Weighted gauge pressure cookers rely on a heavy weight that regulates steam pressure through physical movement, providing consistent and reliable pressure ideal for long, slow pressure-cooking of pet food. Digital sensor pressure cookers offer precise control with programmable settings and real-time pressure monitoring, allowing for customized cooking times and temperatures tailored to specific pet dietary needs. Choosing between these two depends on the desired level of control and convenience, with weighted gauge models favoring simplicity and digital sensors emphasizing versatility.

Table of Comparison

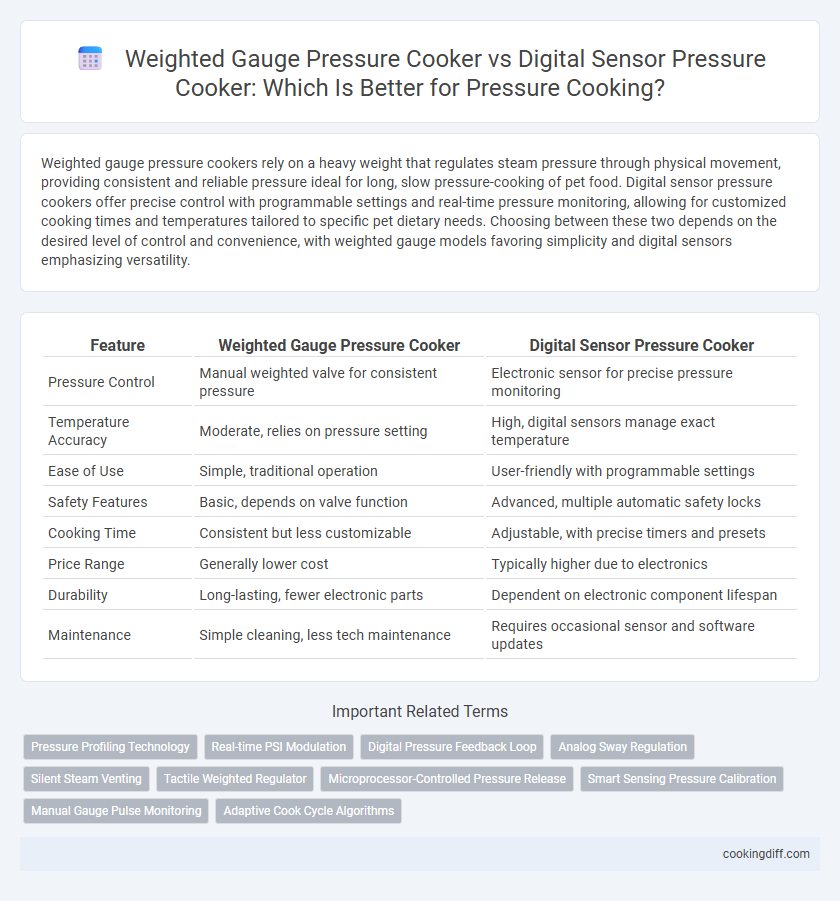

| Feature | Weighted Gauge Pressure Cooker | Digital Sensor Pressure Cooker |

|---|---|---|

| Pressure Control | Manual weighted valve for consistent pressure | Electronic sensor for precise pressure monitoring |

| Temperature Accuracy | Moderate, relies on pressure setting | High, digital sensors manage exact temperature |

| Ease of Use | Simple, traditional operation | User-friendly with programmable settings |

| Safety Features | Basic, depends on valve function | Advanced, multiple automatic safety locks |

| Cooking Time | Consistent but less customizable | Adjustable, with precise timers and presets |

| Price Range | Generally lower cost | Typically higher due to electronics |

| Durability | Long-lasting, fewer electronic parts | Dependent on electronic component lifespan |

| Maintenance | Simple cleaning, less tech maintenance | Requires occasional sensor and software updates |

Introduction to Pressure-Cooking: Gauges vs Sensors

Weighted gauge pressure cookers use a simple weight to regulate pressure by releasing steam at a preset pressure level, ensuring consistent cooking. Digital sensor pressure cookers employ electronic sensors to monitor and adjust pressure and temperature with high precision for customizable cooking settings. Both types optimize pressure-cooking by maintaining ideal pressure, but digital models offer enhanced control and safety features.

How Weighted Gauge Pressure Cookers Work

Weighted gauge pressure cookers operate by using a weight that sits on a vent pipe, which regulates the pressure inside the pot by allowing excess steam to escape at a set pressure level. This mechanical system maintains a steady cooking pressure without electronic components, making it simple and reliable for traditional pressure-cooking methods.

- Weight mechanism controls pressure - The weight creates audible hissing sounds as it releases excess steam to maintain a consistent pressure.

- No electronic sensors involved - Pressure regulation depends entirely on the physical presence and movement of the weighted gauge.

- Pressure level depends on weight size - Different weighted gauges correspond to different pressure ratings essential for cooking various foods.

Weighted gauge pressure cookers provide a straightforward, effective method of pressure control favored for its durability and ease of use.

Digital Sensor Pressure Cookers: Function and Features

Digital sensor pressure cookers use advanced microprocessor technology to monitor and adjust cooking parameters such as temperature and pressure in real-time, ensuring precise and consistent results. These cookers feature programmable settings and touchscreen interfaces for customizable cooking modes, enhanced safety protocols, and automatic pressure release mechanisms. Unlike weighted gauge pressure cookers, digital sensor models offer greater versatility and convenience by integrating smart functions that simplify complex cooking tasks.

Cooking Precision: Accuracy of Weighted Gauges vs Digital Sensors

Weighted gauge pressure cookers maintain pressure through a simple weighted mechanism that fluctuates slightly, offering reliable but less precise control. Digital sensor pressure cookers use advanced sensors to monitor and adjust cooking pressure with high accuracy, providing consistent results.

Weighted gauge cookers are favored for their durability and straightforward operation, but pressure levels may vary by a few psi, affecting cooking precision. Digital sensors deliver exact pressure control, improving cooking consistency and enabling programmable settings for diverse recipes. Home cooks seeking precise cooking outcomes often prefer digital sensor cookers for their accuracy and versatility in pressure management.

Safety Comparison: Traditional vs Modern Pressure Cookers

Which pressure cooker offers better safety features, weighted gauge or digital sensor models? Weighted gauge pressure cookers rely on a mechanical weight to regulate steam pressure, providing a simple and reliable safety mechanism that has proven effective over decades. Digital sensor pressure cookers incorporate electronic controls and multiple sensors to monitor pressure and temperature precisely, reducing the risk of over-pressurization but requiring regular maintenance to ensure sensor accuracy.

Ease of Use: Manual Control vs Digital Interfaces

| Weighted Gauge Pressure Cooker | Operates using a simple weighted valve to maintain pressure, allowing intuitive manual control and real-time pressure adjustments. Its mechanical design requires user experience to manage cooking times and pressure levels effectively. |

| Digital Sensor Pressure Cooker | Features preset digital interfaces with touch controls and automated sensors, providing precise pressure regulation and user-friendly programming options. It offers convenience with programmable cooking cycles, timers, and alerts for consistent results. |

| Ease of Use Comparison | Weighted gauge cookers depend on tactile feedback and manual monitoring, which can be challenging for beginners, while digital sensor cookers simplify the process through automation and guided interfaces, enhancing usability and reducing guesswork during pressure-cooking. |

Maintenance and Durability: Weighted Gauge vs Digital Sensor

Weighted gauge pressure cookers feature simple mechanical parts that require minimal maintenance and offer long-lasting durability, often functioning reliably for decades without electronic failures. Digital sensor pressure cookers contain complex electronic components that may need occasional software updates and repairs, potentially increasing long-term maintenance efforts.

The sealed pressure release mechanism in weighted gauge models is less prone to damage from moisture and heat, contributing to a robust design suitable for frequent heavy use. Digital sensor pressure cookers depend on sensitive sensors and electronic controls that can degrade over time, particularly in high-humidity kitchen environments.

Versatility in Cooking Methods and Recipes

Weighted gauge pressure cookers offer reliable pressure regulation through a simple, visible weight system, making them ideal for traditional recipes and consistent cooking results. They excel in versatility by accommodating a wide range of cooking methods such as steaming, braising, and slow cooking without complex settings.

Digital sensor pressure cookers provide precise control over pressure levels and cooking times, enhancing flexibility for diverse recipes like yogurt making, cake baking, and multi-stage cooking. Their programmable features allow users to customize and save cooking profiles, increasing efficiency and adaptability in the kitchen.

Energy Efficiency: Analog vs Digital Pressure Cookers

Weighted gauge pressure cookers maintain pressure through a physical weight, offering consistent energy use with minimal electronic components. Digital sensor pressure cookers optimize energy consumption by continuously adjusting temperature and pressure, potentially enhancing cooking efficiency.

- Analog Pressure Control - Weighted gauge models rely on simple mechanical systems that evenly distribute heat but lack real-time energy adjustments.

- Energy Consumption - Digital sensor cookers often reduce energy usage by automatically modulating cooking cycles based on precise sensory feedback.

- Operational Efficiency - Sensors in digital cookers enable faster cooking times and reduced power consumption compared to the steady pressure of weighted gauge cookers.

Related Important Terms

Pressure Profiling Technology

Weighted gauge pressure cookers rely on a mechanical pressure regulator that maintains consistent pressure by releasing steam at specific levels, whereas digital sensor pressure cookers use advanced Pressure Profiling Technology to precisely monitor and adjust internal pressure and temperature throughout the cooking process. This technology enables customizable cooking programs and real-time adjustments, resulting in improved consistency, flavor retention, and energy efficiency compared to traditional weighted gauge models.

Real-time PSI Modulation

Weighted gauge pressure cookers regulate pressure through a physical weight that maintains a steady PSI by releasing steam when the set pressure level is reached, providing real-time mechanical pressure control. Digital sensor pressure cookers utilize electronic sensors to monitor and adjust PSI more precisely and dynamically, offering accurate real-time modulation for optimal cooking performance.

Digital Pressure Feedback Loop

Digital sensor pressure cookers utilize a precise pressure feedback loop that continuously monitors internal pressure and adjusts heat to maintain optimal cooking conditions, ensuring consistent results. Weighted gauge pressure cookers rely on manual adjustments through the weight on the vent, which offers less accuracy and can lead to pressure fluctuations during cooking.

Analog Sway Regulation

Weighted gauge pressure cookers utilize a traditional analog sway regulation system that maintains pressure by physically adjusting the weight on the vent, providing reliable and consistent steam release. Digital sensor pressure cookers rely on electronic sensors and microprocessors for precise pressure control but lack the tactile feedback and mechanical simplicity of analog sway regulation found in weighted gauges.

Silent Steam Venting

Weighted gauge pressure cookers release steam through a weighted valve, producing a characteristic hissing sound during pressure regulation, while digital sensor pressure cookers utilize electronic controls that enable silent steam venting by precisely monitoring and adjusting internal pressure. Silent steam venting in digital models enhances kitchen comfort and safety by minimizing noise and preventing sudden steam bursts common in weighted gauge systems.

Tactile Weighted Regulator

The tactile weighted regulator in pressure cookers provides a reliable, physical method for maintaining consistent pressure by adjusting weight and steam release, ensuring precise cooking without electronic dependency. Unlike digital sensor pressure cookers, the weighted gauge model offers simplicity, durability, and immediate tactile feedback, making it ideal for traditional pressure-cooking techniques.

Microprocessor-Controlled Pressure Release

Microprocessor-controlled pressure cookers use digital sensors to precisely manage pressure release, ensuring consistent cooking results and enhanced safety compared to weighted gauge pressure cookers that rely on steam weight for pressure regulation. The digital sensor technology enables adaptive pressure adjustments and automated release, reducing the risk of overcooking and providing greater convenience and accuracy in pressure-cooking.

Smart Sensing Pressure Calibration

Weighted gauge pressure cookers rely on a mechanical weight to maintain consistent pressure, providing reliable and straightforward pressure control during cooking. Digital sensor pressure cookers use advanced smart sensing technology to precisely monitor and calibrate internal pressure, ensuring optimal cooking performance and safety through real-time adjustments.

Manual Gauge Pulse Monitoring

Weighted gauge pressure cookers rely on manual pulse monitoring through a visible weight that jiggles to maintain steady pressure, providing a tactile and auditory cue for pressure regulation. Digital sensor pressure cookers use built-in sensors to automatically monitor and adjust pressure levels, offering precision control without requiring manual intervention.

Weighted gauge pressure cooker vs digital sensor pressure cooker for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com