Aluminum pressure cookers heat up quickly and offer excellent thermal conductivity, making them efficient for pressure-cooking, but they may react with acidic ingredients and discolor over time. Stainless steel pressure cookers provide superior durability, resist corrosion, and do not affect food flavor, making them ideal for long-term use. Choosing between aluminum and stainless steel pressure cookers depends on priorities like heat performance, maintenance, and long-term safety for pet food preparation.

Table of Comparison

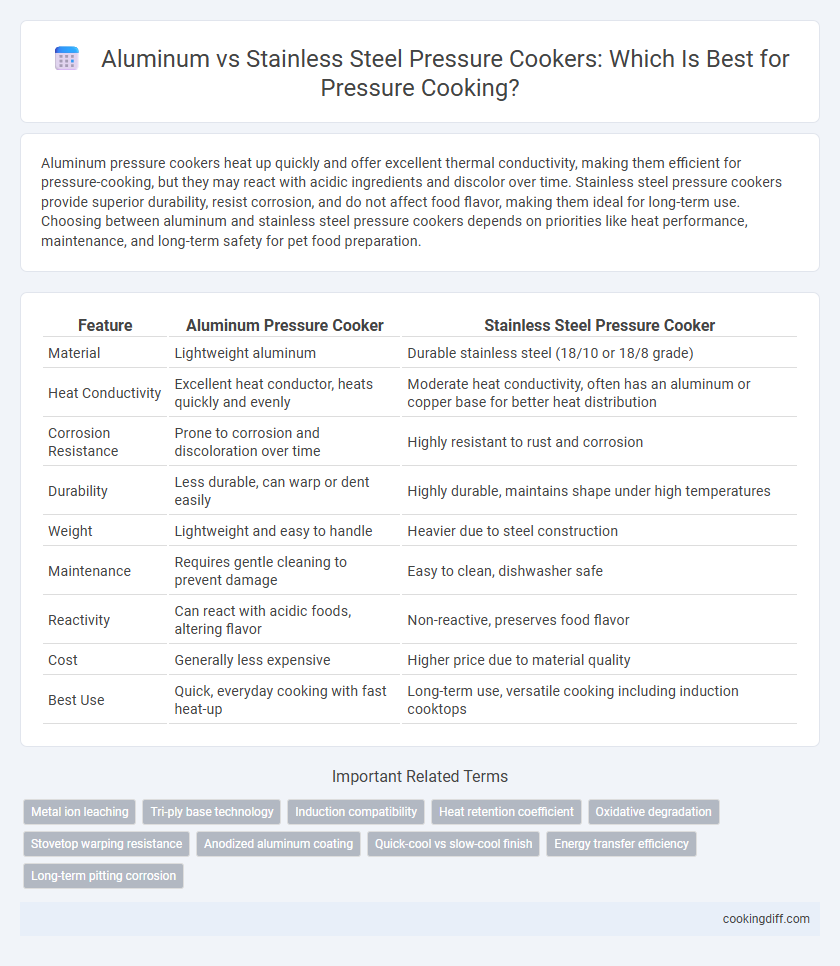

| Feature | Aluminum Pressure Cooker | Stainless Steel Pressure Cooker |

|---|---|---|

| Material | Lightweight aluminum | Durable stainless steel (18/10 or 18/8 grade) |

| Heat Conductivity | Excellent heat conductor, heats quickly and evenly | Moderate heat conductivity, often has an aluminum or copper base for better heat distribution |

| Corrosion Resistance | Prone to corrosion and discoloration over time | Highly resistant to rust and corrosion |

| Durability | Less durable, can warp or dent easily | Highly durable, maintains shape under high temperatures |

| Weight | Lightweight and easy to handle | Heavier due to steel construction |

| Maintenance | Requires gentle cleaning to prevent damage | Easy to clean, dishwasher safe |

| Reactivity | Can react with acidic foods, altering flavor | Non-reactive, preserves food flavor |

| Cost | Generally less expensive | Higher price due to material quality |

| Best Use | Quick, everyday cooking with fast heat-up | Long-term use, versatile cooking including induction cooktops |

Introduction to Aluminum vs Stainless Steel Pressure Cookers

Aluminum and stainless steel are the two most common materials used in pressure cookers, each offering unique benefits for cooking. Understanding their differences helps in selecting the ideal pressure cooker for durability, heat conductivity, and maintenance.

- Aluminum Pressure Cookers - Lightweight and excellent heat conductors, aluminum cookers heat food quickly but may react with acidic ingredients.

- Stainless Steel Pressure Cookers - Known for durability and resistance to corrosion, stainless steel models provide even cooking and better longevity.

- Material Impact on Cooking - Aluminum's fast heat response suits quick cooking while stainless steel's sturdiness supports high-pressure cooking and long-term use.

Material Composition and Durability Comparison

Aluminum pressure cookers are lightweight and offer excellent heat conductivity, making them energy-efficient for quick cooking. However, aluminum is prone to corrosion and can react with acidic foods, potentially affecting flavor and safety.

Stainless steel pressure cookers boast superior durability and resistance to rust, staining, and corrosion due to their strong alloy composition, including chromium and nickel. These cookers maintain their appearance over time and provide a non-reactive cooking surface, ensuring food integrity. Although heavier and often more expensive than aluminum models, stainless steel pressure cookers deliver long-term reliability and safety for diverse cooking needs.

Heat Conductivity and Cooking Efficiency

Aluminum pressure cookers offer superior heat conductivity, allowing for faster and more even heat distribution compared to stainless steel models. This efficient heat transfer reduces cooking time and energy consumption, making aluminum ideal for quick pressure-cooking tasks. However, stainless steel pressure cookers excel in durability and resistance to corrosion, though their lower heat conductivity may require higher heat settings to achieve similar cooking efficiency.

Safety Features and Pressure Handling

Which material offers better safety features and pressure handling in pressure cookers, aluminum or stainless steel? Stainless steel pressure cookers provide superior durability and resistance to corrosion, enhancing safety during high-pressure cooking. Aluminum pressure cookers heat up faster but may be less robust under prolonged pressure, making stainless steel a safer choice for consistent pressure handling.

Weight, Portability, and Storage Considerations

Aluminum pressure cookers are lightweight and highly portable, making them ideal for frequent use and easy storage in small kitchens. Stainless steel pressure cookers are heavier but offer superior durability and a sleek appearance suitable for long-term kitchen setup.

- Weight - Aluminum models are significantly lighter, reducing user strain during handling and transportation.

- Portability - The lightweight nature of aluminum enhances portability, especially for outdoor cooking or travel.

- Storage Considerations - Stainless steel pressure cookers require more storage space due to their heavier and bulkier design.

Choosing between aluminum and stainless steel depends on balancing portability needs with durability preferences for pressure cooking.

Maintenance, Cleaning, and Longevity

Aluminum pressure cookers require frequent polishing to prevent discoloration and are prone to scratching, which can affect their performance over time. They are lightweight but may degrade faster with regular exposure to acidic foods and high heat.

Stainless steel pressure cookers offer superior durability and resist rust, making maintenance easier and extending their lifespan significantly. Their non-reactive surface allows for simpler cleaning without the risk of corrosion or staining, ensuring long-term usability.

Pricing and Value for Money

Aluminum pressure cookers are generally more affordable, making them a popular choice for budget-conscious buyers. Their lightweight nature offers good heat conductivity, ensuring efficient cooking at a lower price point.

Stainless steel pressure cookers tend to be pricier but provide superior durability and corrosion resistance, often resulting in longer product lifespan. The higher initial investment in stainless steel models delivers better value for money through enhanced safety and maintenance benefits.

Compatibility with Heat Sources

Aluminum pressure cookers heat up quickly and are compatible with most traditional gas and electric stovetops but generally do not work on induction cooktops. Stainless steel pressure cookers offer superior compatibility, functioning efficiently on gas, electric, induction, and even ceramic cooktops due to their magnetic properties.

- Aluminum cookers and induction heat - Aluminum lacks magnetic properties, rendering it incompatible with induction stovetops requiring a magnetic base.

- Stainless steel and versatility - Stainless steel pressure cookers typically contain a magnetic base, enabling use on all common heat sources including induction.

- Heat conductivity differences - Aluminum provides faster heat conduction, while stainless steel offers durability and more even heat distribution across diverse heat sources.

Health Implications and Food Reactivity

Aluminum pressure cookers may leach small amounts of aluminum into food, raising health concerns especially with acidic or salty dishes. Stainless steel pressure cookers are non-reactive, preventing metal transfer and preserving food safety during high-pressure cooking. Choosing stainless steel reduces the risk of food contamination and potential oxidative reactions that can occur with aluminum cookware.

Related Important Terms

Metal ion leaching

Aluminum pressure cookers tend to exhibit higher levels of metal ion leaching, especially when cooking acidic foods, potentially affecting food safety and taste. Stainless steel pressure cookers, composed primarily of iron, chromium, and nickel, offer superior resistance to corrosion and minimal metal ion leaching, making them a safer choice for long-term use in pressure-cooking applications.

Tri-ply base technology

Aluminum pressure cookers with tri-ply base technology offer superior heat conductivity and fast, even cooking, making them ideal for quick pressure-cooking tasks. Stainless steel pressure cookers with tri-ply base combine durability and corrosion resistance with efficient heat distribution, ensuring long-lasting performance and consistent cooking results.

Induction compatibility

Stainless steel pressure cookers are fully compatible with induction cooktops due to their magnetic properties, ensuring efficient and even heat distribution. Aluminum pressure cookers typically lack induction compatibility unless they feature a special magnetic base, making stainless steel the preferred choice for induction pressure cooking.

Heat retention coefficient

Aluminum pressure cookers offer a high heat retention coefficient, allowing for rapid heat distribution and efficient cooking times, ideal for quick pressure-cooking. Stainless steel pressure cookers have a lower heat retention coefficient but provide durability and even heating with a layered base that compensates for slower heat retention.

Oxidative degradation

Aluminum pressure cookers are prone to oxidative degradation due to their reactive surface, which can deteriorate faster under high heat and pressure during cooking. Stainless steel pressure cookers resist oxidative degradation effectively, maintaining structural integrity and food safety with superior corrosion resistance in pressure-cooking environments.

Stovetop warping resistance

Stainless steel pressure cookers exhibit superior resistance to stovetop warping due to their robust alloy composition and higher melting point compared to aluminum models. Aluminum pressure cookers, while lightweight and efficient in heat conduction, are more prone to deformation under high heat and prolonged use on stovetops.

Anodized aluminum coating

Anodized aluminum pressure cookers offer enhanced corrosion resistance and durability compared to regular aluminum, preventing food reactions and ensuring safer pressure cooking. Stainless steel pressure cookers provide superior strength and non-reactivity, but anodized aluminum combines lightweight convenience with a protective coating that resists warping and extends the lifespan of the cooker.

Quick-cool vs slow-cool finish

Aluminum pressure cookers offer faster heat conduction, enabling quicker cooling times due to their excellent thermal conductivity, while stainless steel pressure cookers cool more slowly because of their lower heat transfer efficiency but provide greater durability and resistance to corrosion. Choosing between these materials depends on whether speed in the quick-cool process or long-term resilience during slow-cool finish is a priority for your pressure-cooking needs.

Energy transfer efficiency

Aluminum pressure cookers offer superior energy transfer efficiency due to aluminum's high thermal conductivity, allowing for faster heat distribution and reduced cooking times. Stainless steel pressure cookers, while more durable and resistant to corrosion, typically have lower thermal conductivity, requiring longer heating periods and slightly higher energy consumption.

Aluminum pressure cooker vs Stainless steel pressure cooker for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com