Pressure cookers use steam pressure to cook food quickly and are ideal for home kitchens due to their size and ease of use. Autoclave cookers generate higher pressure and temperature, primarily for sterilization in medical or industrial settings rather than everyday cooking. Choosing between the two depends on the specific need for food preparation or sterilization, with pressure cookers being the practical choice for culinary purposes.

Table of Comparison

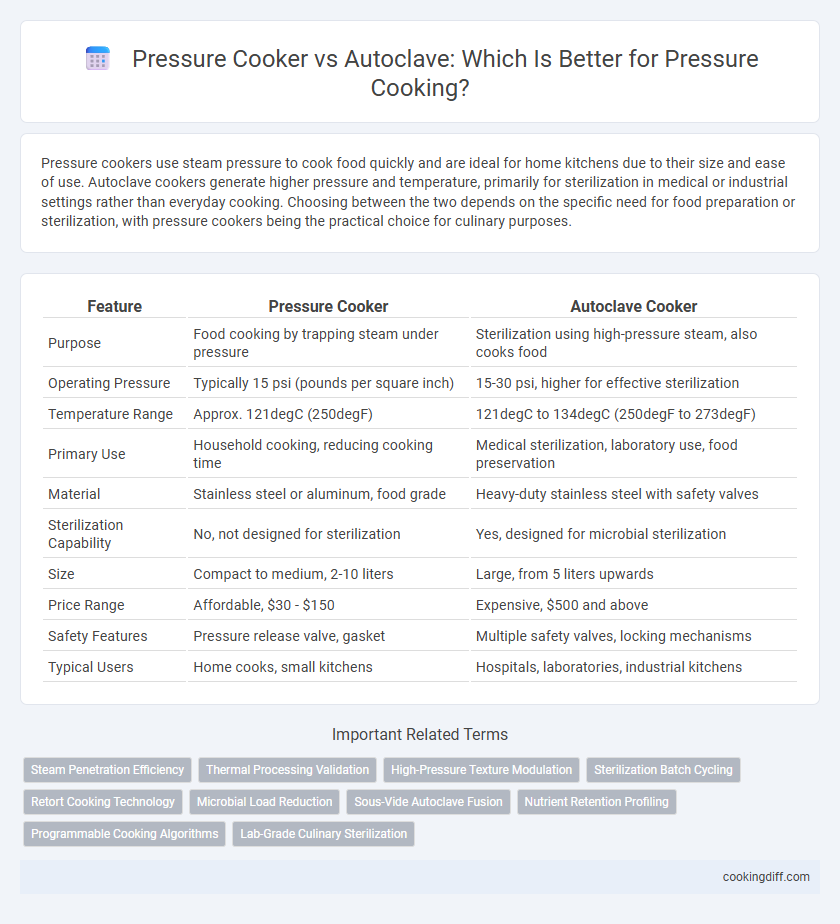

| Feature | Pressure Cooker | Autoclave Cooker |

|---|---|---|

| Purpose | Food cooking by trapping steam under pressure | Sterilization using high-pressure steam, also cooks food |

| Operating Pressure | Typically 15 psi (pounds per square inch) | 15-30 psi, higher for effective sterilization |

| Temperature Range | Approx. 121degC (250degF) | 121degC to 134degC (250degF to 273degF) |

| Primary Use | Household cooking, reducing cooking time | Medical sterilization, laboratory use, food preservation |

| Material | Stainless steel or aluminum, food grade | Heavy-duty stainless steel with safety valves |

| Sterilization Capability | No, not designed for sterilization | Yes, designed for microbial sterilization |

| Size | Compact to medium, 2-10 liters | Large, from 5 liters upwards |

| Price Range | Affordable, $30 - $150 | Expensive, $500 and above |

| Safety Features | Pressure release valve, gasket | Multiple safety valves, locking mechanisms |

| Typical Users | Home cooks, small kitchens | Hospitals, laboratories, industrial kitchens |

Introduction: Pressure Cooker vs Autoclave Cooker

Pressure cookers and autoclave cookers both use high-pressure steam to cook food efficiently, but their primary applications differ significantly. Pressure cookers are designed for household cooking, while autoclave cookers are mainly used for sterilization in medical and laboratory settings.

Pressure cookers operate at lower pressure levels, typically around 15 psi, to reduce cooking times and preserve nutrients. Autoclave cookers achieve higher pressures and temperatures to ensure complete sterilization of equipment and materials.

Understanding Pressure Cookers: Basics and Uses

Pressure cookers utilize steam pressure to cook food quickly while preserving nutrients, making them ideal for everyday kitchen use. Autoclave cookers operate at higher pressures and temperatures, primarily designed for sterilization in medical and laboratory settings rather than typical cooking. Understanding these distinctions helps users select the appropriate device based on cooking needs and safety requirements.

What Is an Autoclave Cooker?

| Autoclave Cooker Definition | An autoclave cooker is a high-pressure device primarily used for sterilization but can also cook food by using saturated steam under pressure. |

| Pressure Levels | Operates at pressures up to 15 psi or higher, ensuring temperatures exceed 121degC (250degF) for effective sterilization and cooking. |

| Use Case | Commonly used in medical sterilization, food preservation, and canning, differentiating it from regular pressure cookers designed mainly for daily cooking tasks. |

Cooking Principles: Pressure Cooker vs Autoclave Cooker

How do the cooking principles of pressure cookers differ from those of autoclave cookers? Pressure cookers use high-pressure steam to raise the boiling point of water, accelerating the cooking process for everyday meals. Autoclave cookers operate at even higher pressures and temperatures, using pressurized steam primarily for sterilization rather than typical cooking tasks.

Safety Features Compared

Pressure cookers incorporate multiple built-in safety features such as pressure release valves, locking lids, and gasket release mechanisms to prevent accidents during cooking. These devices are designed for household use with safety standards that minimize the risk of explosion under normal operating conditions.

Autoclave cookers, used primarily for sterilization in medical and laboratory settings, employ more advanced safety systems including precise pressure monitoring, automatic shutdown protocols, and heavy-duty locking mechanisms. Their rigorous design standards focus on maintaining sterile environments while ensuring operator safety under higher pressure and temperature conditions.

Cooking Results and Food Texture Differences

Pressure cookers use high steam pressure to cook food faster while preserving moisture, resulting in tender textures ideal for everyday meals. Autoclave cookers operate at higher pressures and temperatures primarily for sterilization, often producing firmer textures unsuitable for culinary uses.

- Pressure Cooker yields tender, evenly cooked food - Its moderate pressure preserves natural moisture and flavor, enhancing texture without overcooking.

- Autoclave Cooker produces firmer, sometimes tougher textures - Designed for sterilization, it uses harsher conditions that can alter food structure significantly.

- Cooking results differ due to pressure and temperature settings - Pressure cookers prioritize palatable textures, while autoclaves focus on microbial elimination over culinary quality.

Efficiency and Cooking Time

Pressure cookers use high steam pressure to cook food quickly and efficiently, reducing cooking times by up to 70% compared to conventional methods. Autoclave cookers operate at higher pressures and temperatures, primarily designed for sterilization rather than culinary use.

Pressure cookers are ideal for home cooking, delivering faster meal preparation with energy savings. Autoclaves ensure complete sterilization by maintaining consistent high pressure and heat for extended periods, making them less efficient for everyday cooking. Efficiency in cooking time heavily favors pressure cookers, while autoclaves excel in sterilization processes beyond culinary applications.

Cost and Accessibility

Pressure cookers are generally more affordable and widely accessible for everyday cooking compared to autoclave cookers, which are specialized and costly equipment primarily used for sterilization. Autoclave cookers require a higher initial investment and are less common in household kitchens due to their industrial design and purpose.

- Pressure Cooker Cost - Typically priced between $30 and $150, suitable for home use and budget-conscious consumers.

- Autoclave Cooker Cost - Can exceed $1,000 due to advanced features and sterilization capabilities.

- Accessibility - Pressure cookers are readily available in supermarkets and online stores, unlike autoclave cookers, which are primarily sold through specialized medical or laboratory suppliers.

Common Culinary Applications

Pressure cookers and autoclave cookers both use high-pressure steam to cook food quickly, but pressure cookers are primarily designed for everyday culinary applications such as cooking meats, legumes, and vegetables efficiently at home. Autoclave cookers are more commonly used for sterilization purposes in laboratories and medical settings, with limited use in food preservation or canning processes. The pressure cooker's versatility and ease of use make it the preferred choice for most culinary tasks involving tenderizing tough ingredients and reducing cooking time.

Related Important Terms

Steam Penetration Efficiency

Pressure cookers achieve efficient steam penetration by maintaining high pressure and temperature, rapidly cooking food while preserving nutrients. Autoclave cookers, designed primarily for sterilization, use higher pressures and temperatures, ensuring deeper steam penetration but are less practical for everyday cooking purposes.

Thermal Processing Validation

Pressure cookers and autoclave cookers differ significantly in thermal processing validation, with autoclaves offering precise temperature and pressure controls validated through rigorous industrial standards critical for sterilization. Unlike typical pressure cookers used for home cooking, autoclaves maintain strict parameters to ensure consistent thermal lethality, essential for eliminating microbial contaminants in medical and laboratory settings.

High-Pressure Texture Modulation

Pressure cookers and autoclave cookers both utilize high-pressure steam to rapidly cook food, but autoclave cookers operate at higher pressures (typically up to 121degC and 15 psi) compared to standard pressure cookers (usually around 15 psi and 120degC), enabling more precise texture modulation for denser, tougher ingredients. This high-pressure environment in autoclaves allows greater control over protein denaturation and starch gelatinization, resulting in optimized texture and enhanced flavor profiles in foods requiring intensive cooking processes.

Sterilization Batch Cycling

Pressure cookers achieve sterilization through high-temperature steam under pressure, suitable for batch cooking of food but lack precise control for repeated sterilization cycles. Autoclave cookers are specifically designed for sterilization batch cycling with regulated pressure, temperature, and timing, ensuring consistent microbial inactivation ideal for medical or laboratory use.

Retort Cooking Technology

Pressure cookers utilize steam pressure to cook food quickly by raising the boiling point of water, while autoclave cookers apply higher pressure and temperature for sterilization and retort cooking technology, ensuring shelf-stable food products. Retort cooking technology in autoclave cookers enables uniform heat penetration and microbial inactivation, critical for preserving nutritional quality and extending shelf life in canned and packaged foods.

Microbial Load Reduction

Pressure cookers achieve microbial load reduction by utilizing steam pressure typically around 15 psi, raising temperatures to 121degC, effectively inactivating common foodborne pathogens and spores. Autoclave cookers, designed for sterilization in medical or laboratory settings, maintain precise control over temperature and pressure cycles, ensuring complete microbial sterilization beyond standard cooking requirements.

Sous-Vide Autoclave Fusion

Sous-vide autoclave fusion combines precise temperature control of sous-vide with the high-pressure environment of autoclave cookers, enabling faster cooking times while preserving texture and nutrients more effectively than traditional pressure cookers. This method offers enhanced flavor infusion and food safety by leveraging sterilization standards typical of autoclaves alongside the gentle, even cooking characteristic of sous-vide techniques.

Nutrient Retention Profiling

Pressure cookers and autoclave cookers both utilize high-pressure steam to accelerate cooking times while preserving nutrient integrity, but autoclaves typically achieve higher pressure levels, resulting in greater microbial sterilization but potential overcooking of heat-sensitive nutrients. Nutrient retention profiling reveals pressure cookers maintain higher levels of vitamins C and B-complex due to lower pressure and shorter cooking durations, whereas autoclave cookers excel in food safety but may compromise delicate nutrient content.

Programmable Cooking Algorithms

Pressure cookers use programmable cooking algorithms to precisely control temperature and pressure, ensuring efficient and consistent food preparation. Autoclave cookers employ similar algorithms but at higher pressure and temperature settings designed primarily for sterilization rather than culinary purposes, making pressure cookers more suitable for everyday cooking applications.

Pressure Cooker vs Autoclave Cooker for cooking. Infographic

cookingdiff.com

cookingdiff.com