Traditional stock reduction relies on prolonged simmering to concentrate flavors, resulting in deeper, richer taste profiles but requiring extensive time. Pressure-infused reduction leverages high pressure to accelerate liquid evaporation and flavor extraction, achieving similar or enhanced intensity in a fraction of the time. This method preserves aromatic compounds more effectively while ensuring optimal texture and nutrient retention in pressure-cooking applications.

Table of Comparison

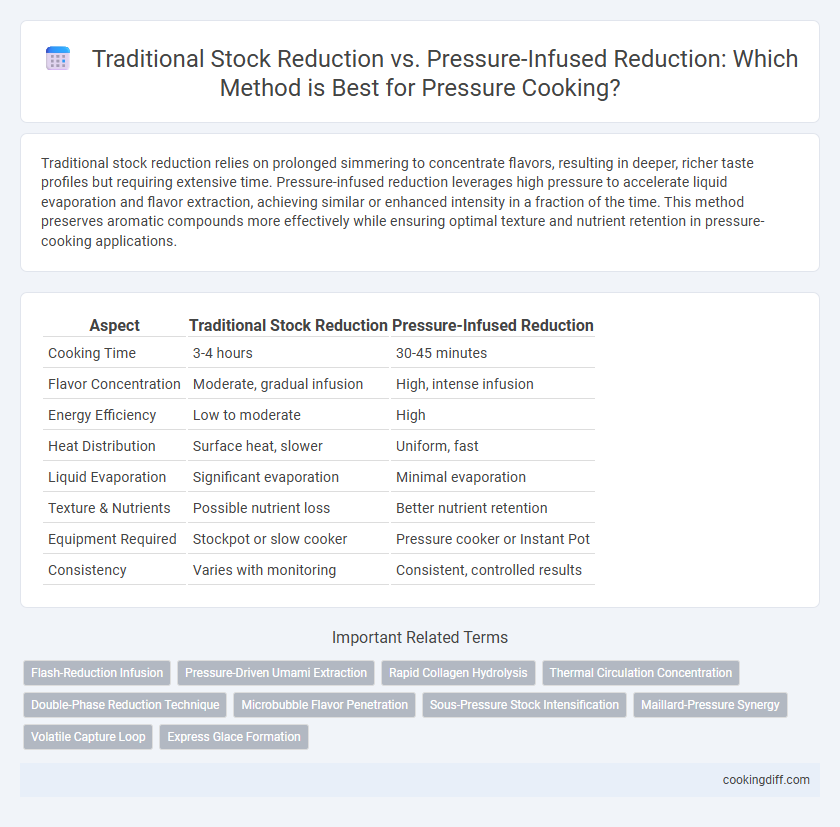

| Aspect | Traditional Stock Reduction | Pressure-Infused Reduction |

|---|---|---|

| Cooking Time | 3-4 hours | 30-45 minutes |

| Flavor Concentration | Moderate, gradual infusion | High, intense infusion |

| Energy Efficiency | Low to moderate | High |

| Heat Distribution | Surface heat, slower | Uniform, fast |

| Liquid Evaporation | Significant evaporation | Minimal evaporation |

| Texture & Nutrients | Possible nutrient loss | Better nutrient retention |

| Equipment Required | Stockpot or slow cooker | Pressure cooker or Instant Pot |

| Consistency | Varies with monitoring | Consistent, controlled results |

Introduction to Stock Reduction Techniques

Traditional stock reduction involves simmering broth slowly over low heat to concentrate flavors through evaporation. This method can take several hours to achieve a rich, flavorful stock.

Pressure-infused reduction accelerates this process by utilizing high pressure to increase boiling points and speed up flavor extraction. This technique significantly reduces cooking time while preserving the depth and complexity of the stock.

What is Traditional Stock Reduction?

| Traditional Stock Reduction | Traditional stock reduction involves simmering broth or stock over extended periods, often several hours, to concentrate flavors and thicken the liquid by evaporating water. This slow cooking method relies on gradual heat and time to extract collagen, gelatin, and nutrients from bones and vegetables, creating a rich and flavorful base. The process requires constant attention to maintain a gentle simmer and prevent boiling, ensuring clarity and depth in the final stock. |

The Pressure-Infused Reduction Method Explained

The Pressure-Infused Reduction Method accelerates stock concentration by using high-pressure steam to enhance the extraction of flavors and gelatin from bones and vegetables. This technique significantly reduces cooking time compared to Traditional Stock Reduction, which relies on prolonged simmering.

Under pressure, the increased temperature raises the vapor point, intensifying the breakdown of collagen and minerals into the stock. This results in a rich, deeply flavored reduction with superior mouthfeel and nutritional density.

Key Differences Between Traditional and Pressure-Infused Reduction

What are the key differences between traditional stock reduction and pressure-infused reduction in pressure-cooking? Traditional stock reduction relies on prolonged simmering to evaporate liquid and concentrate flavors, often taking several hours. Pressure-infused reduction achieves faster concentration by using high pressure to raise boiling points, significantly cutting cooking time while intensifying taste and nutrients.

Flavor Concentration: Slow Simmer vs Pressure Cooking

Traditional stock reduction relies on slow simmering for hours, allowing gradual evaporation that deepens flavor complexity and concentrates umami. Pressure-infused reduction uses high-pressure steam to drastically cut cooking time while intensifying flavors by extracting collagen and amino acids more efficiently. Both methods enhance flavor concentration, but pressure cooking delivers rich, robust stock in a fraction of the time.

Time Efficiency: Classic Methods vs Modern Shortcuts

Traditional stock reduction requires several hours of simmering to concentrate flavors effectively, while pressure-infused reduction drastically cuts this time to under an hour without compromising taste. This method leverages high-pressure steam to accelerate the extraction of flavors and gelatin from bones, optimizing overall cooking efficiency.

- Time Savings - Pressure-infused reduction can reduce cooking time by up to 75% compared to classic simmering methods.

- Flavor Concentration - Despite the shorter duration, pressure-cooking achieves a rich, deeply concentrated stock equivalent to traditional reductions.

- Energy Efficiency - Reduced cooking times translate to lower energy use and less heat generation in the kitchen.

Nutrient Retention in Both Reduction Processes

Traditional stock reduction involves slow simmering, which often leads to significant nutrient loss due to prolonged heat exposure. Pressure-infused reduction in pressure-cooking preserves more vitamins and minerals by reducing cooking time and limiting oxidation.

Pressure-cooking maintains higher levels of heat-sensitive nutrients like vitamin C and folate compared to traditional methods. The sealed environment minimizes nutrient leaching into cooking water, enhancing overall nutrient retention. This makes pressure-infused reduction a superior choice for preserving the nutritional profile of stocks and broths.

Equipment and Tools: Pots vs Pressure Cookers

Traditional stock reduction relies on large, heavy pots designed for slow simmering over extended periods, requiring constant heat management and occasional stirring to prevent burning. Pressure-infused reduction utilizes specialized pressure cookers that create a sealed environment, increasing internal pressure and temperature to drastically cut cooking times while intensifying flavor extraction. Pressure cookers often feature safety valves, tight-sealing lids, and durable materials optimized for sustained high-pressure use, contrasting with the open design and lower heat tolerance of conventional pots.

Culinary Applications: When to Use Each Method

Traditional stock reduction allows for gradual flavor development and is preferred for delicate stocks requiring clarity and subtlety. Pressure-infused reduction excels in speeding up the concentration process, ideal for robust, quick culinary preparations.

- Delicate Soups and Sauces - Use traditional reduction to maintain clarity and nuanced flavors in refined dishes.

- Time-Sensitive Meals - Opt for pressure-infused reduction to rapidly intensify flavors without prolonged cooking.

- Hearty Broths - Pressure-infused methods enhance richness quickly, perfect for stews and braises.

Related Important Terms

Flash-Reduction Infusion

Flash-Reduction Infusion in pressure-cooking accelerates the traditional stock reduction process by trapping steam and intensifying heat, which enhances flavor concentration and reduces cooking time by up to 70%. This method preserves volatile aromatics and nutrients more effectively than open simmering, resulting in richer, more complex stocks with improved mouthfeel.

Pressure-Driven Umami Extraction

Pressure-infused reduction in pressure-cooking accelerates umami extraction by intensifying molecular breakdown of proteins and amino acids under high pressure, yielding richer, deeper flavors compared to traditional slow stock reduction. This method significantly shortens cooking time while maximizing savory compounds like glutamates, enhancing the overall taste profile of broths and sauces.

Rapid Collagen Hydrolysis

Pressure-infused reduction accelerates collagen hydrolysis by exposing bones and connective tissues to high-pressure steam, significantly shortening the time required to extract gelatin compared to traditional stock reduction methods that rely on prolonged simmering. This rapid collagen breakdown results in a richer, more viscous stock with enhanced mouthfeel and depth of flavor in a fraction of the time.

Thermal Circulation Concentration

Traditional stock reduction relies on slow simmering to evaporate liquids and concentrate flavors, resulting in uneven thermal circulation and longer cooking times. Pressure-infused reduction enhances thermal circulation by increasing internal pressure and temperature, accelerating flavor concentration while preserving nutrients and depth.

Double-Phase Reduction Technique

The Double-Phase Reduction Technique combines traditional stock reduction with pressure-infused reduction by first simmering the stock to concentrate flavors before applying pressure cooking to accelerate and deepen the infusion of taste compounds. This method maximizes flavor extraction while significantly reducing cooking time compared to conventional reduction processes.

Microbubble Flavor Penetration

Traditional stock reduction relies on prolonged simmering to concentrate flavors, often resulting in slower infusion of taste compounds. Pressure-infused reduction utilizes microbubble technology during pressure-cooking to accelerate flavor penetration at a molecular level, enhancing depth and intensity in a fraction of the time.

Sous-Pressure Stock Intensification

Traditional stock reduction relies on prolonged simmering to concentrate flavors, often consuming hours, while pressure-infused reduction accelerates this process by using high pressure and steam to enhance flavor extraction within a fraction of the time. Sous-pressure stock intensification combines controlled pressure cooking with precise temperature regulation, yielding deeply concentrated, richly flavored stocks with improved gelatin extraction and reduced cooking time compared to conventional methods.

Maillard-Pressure Synergy

Traditional stock reduction relies on slow simmering to concentrate flavors through evaporation, often requiring hours to develop deep, caramelized notes. Pressure-infused reduction leverages increased temperature and pressure to accelerate Maillard reactions, producing rich, complex flavors and enhanced aroma profiles in a fraction of the time.

Volatile Capture Loop

Traditional stock reduction relies on prolonged simmering to concentrate flavors, often losing key aromatics due to evaporation; the pressure-infused reduction method employs a volatile capture loop that traps and reintroduces these aromatic compounds, enhancing flavor intensity and preserving essential oils. This closed-loop system accelerates reduction time while maximizing volatile retention, resulting in richer, more robust stock profiles compared to conventional methods.

Traditional Stock Reduction vs Pressure-Infused Reduction for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com