Standard inner pots for pressure cooking often feature stainless steel, providing excellent durability, fast heat conduction, and easy cleaning. Ceramic-coated inner pots offer a non-stick surface that reduces the need for oil and simplifies food release while maintaining even heat distribution. Choosing between them depends on priorities like durability, ease of maintenance, and cooking preferences.

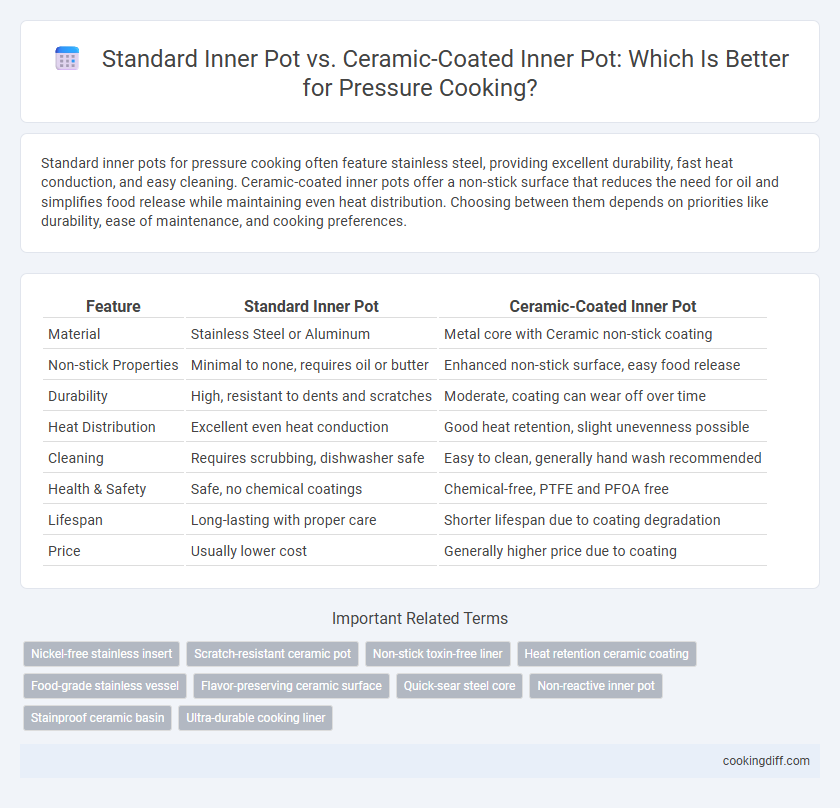

Table of Comparison

| Feature | Standard Inner Pot | Ceramic-Coated Inner Pot |

|---|---|---|

| Material | Stainless Steel or Aluminum | Metal core with Ceramic non-stick coating |

| Non-stick Properties | Minimal to none, requires oil or butter | Enhanced non-stick surface, easy food release |

| Durability | High, resistant to dents and scratches | Moderate, coating can wear off over time |

| Heat Distribution | Excellent even heat conduction | Good heat retention, slight unevenness possible |

| Cleaning | Requires scrubbing, dishwasher safe | Easy to clean, generally hand wash recommended |

| Health & Safety | Safe, no chemical coatings | Chemical-free, PTFE and PFOA free |

| Lifespan | Long-lasting with proper care | Shorter lifespan due to coating degradation |

| Price | Usually lower cost | Generally higher price due to coating |

Introduction to Pressure-Cooker Inner Pots

Pressure-cooking relies heavily on the quality and material of the inner pot to ensure even heat distribution and optimal cooking results. Standard inner pots are typically made of stainless steel, offering durability and excellent resistance to high temperatures.

Ceramic-coated inner pots provide a non-stick surface that simplifies cleaning and reduces the need for excessive oil, enhancing healthy cooking. These pots also improve heat retention but may require more careful handling to avoid chipping or damage during pressure cooking.

Material Overview: Stainless Steel vs. Ceramic-Coated

Which inner pot material is better for pressure-cooking, stainless steel or ceramic-coated? Stainless steel inner pots are durable, resistant to scratches and corrosion, and provide even heat distribution for consistent cooking results. Ceramic-coated inner pots offer a non-stick surface with easier cleaning but may be less durable over time and prone to chipping under high pressure conditions.

Heat Distribution and Cooking Performance

Standard inner pots made of stainless steel offer uniform heat distribution critical for consistent pressure-cooking performance, while ceramic-coated inner pots provide more gradual heat transfer, reducing the risk of hotspots and burning. The non-reactive surface of ceramic-coated pots also helps preserve food flavor and texture during high-pressure cooking cycles.

- Heat distribution efficiency - Stainless steel conducts heat quickly and evenly, optimizing cooking speed.

- Non-stick properties - Ceramic coating minimizes sticking, easing cleanup without compromising heat flow.

- Durability under pressure - Standard pots withstand multiple pressure cycles without wear, whereas ceramic coatings may chip over time.

Choosing between these inner pots depends on balancing heat performance with ease of maintenance and longevity.

Durability and Longevity Comparison

Standard inner pots are typically made from stainless steel, offering exceptional durability and resistance to scratches and dents, making them ideal for long-term use. Ceramic-coated inner pots, while providing a non-stick surface, tend to wear down over time and are more susceptible to chipping and degradation with frequent pressure-cooking.

- Standard Inner Pot Durability - Stainless steel construction resists corrosion and physical damage, ensuring long-lasting performance.

- Ceramic-Coated Pot Longevity - The ceramic coating can deteriorate after extended use, reducing its effectiveness and lifespan.

- Maintenance Impact - Standard pots require minimal care to maintain durability, while ceramic-coated pots need gentle handling to avoid scratching and chipping.

Non-stick Properties: Pros and Cons

Standard inner pots typically feature a traditional non-stick coating that offers reliable food release and easy cleaning, but they may degrade faster with frequent use and abrasive utensils. Ceramic-coated inner pots provide a chemical-free, eco-friendly non-stick surface that is generally more scratch-resistant but can lose effectiveness over time if not properly maintained.

- Standard Non-Stick Efficiency - Provides excellent initial food release but may wear off due to high heat or metal tools.

- Ceramic Coating Safety - Free from PTFE and PFOA, offering a safer option for health-conscious cooks.

- Durability Trade-off - Ceramic coatings tend to be more scratch-resistant but require gentle cleaning to maintain non-stick properties.

Ease of Cleaning and Maintenance

Standard inner pots for pressure cooking are typically made of stainless steel, which offers durability and resistance to staining, making them relatively easy to clean with common kitchen detergents. Ceramic-coated inner pots provide a non-stick surface that simplifies food release and reduces the need for vigorous scrubbing, but the coating requires careful handling to prevent chipping and maintain its effectiveness. Regular maintenance of both types involves thorough drying to avoid rust in standard pots and gentle cleaning methods to preserve the ceramic coating's longevity.

Food Safety and Health Considerations

Standard inner pots for pressure cookers are typically made of stainless steel, which is non-reactive and resistant to corrosion, ensuring food safety during high-pressure cooking. Ceramic-coated inner pots offer a non-toxic, PTFE/PFOA-free surface that reduces the risk of harmful chemical exposure but may be less durable over time. Both materials avoid leaching harmful substances into food, but ceramic coatings require careful handling to prevent chipping and maintain health benefits.

Compatibility with Recipes and Ingredients

Standard inner pots are typically made of stainless steel, providing excellent heat distribution and durability, making them compatible with a wide range of pressure-cooking recipes and ingredients. Their non-reactive nature ensures that acidic foods like tomatoes or citrus maintain their flavor without any metallic taste.

Ceramic-coated inner pots offer a non-stick surface that can enhance the cooking of delicate ingredients and reduce the need for oils, making them ideal for recipes that require gentle heat and even cooking. However, they may be less suitable for high-heat recipes or those involving metal utensils, as the ceramic coating can wear over time and affect recipe compatibility.

Cost and Value for Money

| Standard Inner Pot | More affordable upfront cost, typically made from stainless steel or aluminum, offering durability and even heat distribution. Provides strong value for budget-conscious users prioritizing long-term reliability and fast cooking. Often compatible with most electric pressure cookers, ensuring versatility without extra investment. |

| Ceramic-Coated Inner Pot | Higher initial price due to non-stick, eco-friendly coating that reduces need for oil and simplifies cleaning. Offers value through health benefits and ease of maintenance, but coating may wear over time, potentially requiring earlier replacement. Ideal for users prioritizing non-toxic materials and gentle cooking surfaces despite greater upfront cost. |

Related Important Terms

Nickel-free stainless insert

Pressure cookers featuring a nickel-free stainless steel inner pot offer superior durability and resistance to corrosion compared to ceramic-coated inner pots, which may chip or wear over time. Nickel-free stainless steel ensures safe, allergen-free cooking while maintaining even heat distribution for optimal pressure-cooking performance.

Scratch-resistant ceramic pot

Scratch-resistant ceramic-coated inner pots for pressure cooking offer enhanced durability and non-reactive cooking surfaces that preserve food flavor and prevent metal leaching compared to standard stainless steel or aluminum inner pots. These ceramic coatings provide superior heat distribution and are easier to clean, making them ideal for frequent use and maintaining long-term pot integrity.

Non-stick toxin-free liner

Ceramic-coated inner pots offer a toxin-free, non-stick surface ideal for pressure cooking, preventing harmful chemical leaching often associated with traditional non-stick coatings. Standard inner pots typically lack this ceramic layer, making ceramic-coated options safer and easier to clean while maintaining food integrity under high pressure.

Heat retention ceramic coating

Ceramic-coated inner pots excel in heat retention during pressure cooking, promoting even temperature distribution and reducing energy consumption compared to standard stainless steel pots. This enhanced heat retention ensures consistent cooking results and protects delicate ingredients from overcooking or hot spots.

Food-grade stainless vessel

Food-grade stainless steel inner pots offer superior durability and non-reactive cooking surfaces essential for safe pressure-cooking, resisting corrosion and maintaining flavor integrity. Ceramic-coated inner pots provide a non-stick surface but may wear over time, potentially compromising safety and performance compared to the robust stainless steel vessels.

Flavor-preserving ceramic surface

The ceramic-coated inner pot in pressure cookers offers a non-reactive, flavor-preserving surface that prevents metal-induced taste alterations, enhancing the natural aromas and richness of cooked foods. Its smooth, non-porous texture resists staining and retains heat evenly, providing consistent cooking results while maintaining the integrity of delicate flavors compared to standard stainless steel or aluminum inner pots.

Quick-sear steel core

The Quick-sear steel core in a standard inner pot ensures rapid and even heat distribution, optimizing pressure-cooking efficiency and reducing cooking time. Ceramic-coated inner pots offer non-stick benefits but typically lack the same thermal conductivity and searing performance, making them less ideal for quick-sear applications.

Non-reactive inner pot

Non-reactive inner pots, such as ceramic-coated options, prevent chemical reactions with acidic or alkaline ingredients during pressure cooking, preserving food flavor and preventing discoloration. Standard stainless steel inner pots offer durability and corrosion resistance but may sometimes impart a metallic taste when cooking highly acidic dishes.

Stainproof ceramic basin

Ceramic-coated inner pots in pressure cookers offer superior stainproof properties compared to standard stainless steel or aluminum pots, preventing discoloration from acidic or colorful foods. This stain resistance enhances durability and maintains a clean, attractive cooking surface over extended use, making ceramic basins ideal for consistent, hassle-free pressure cooking.

Standard inner pot vs ceramic-coated inner pot for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com