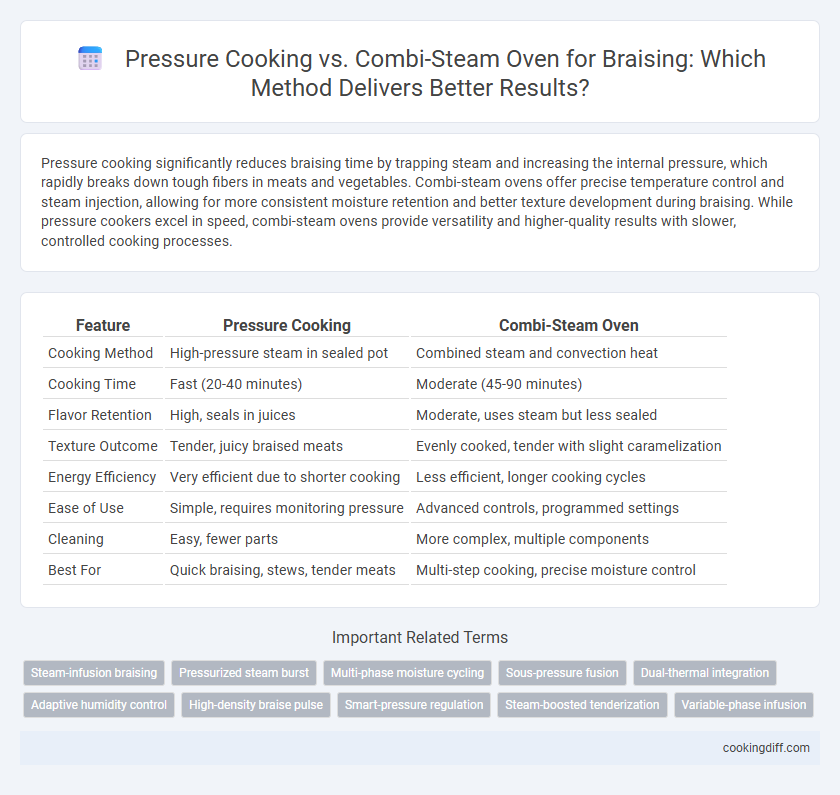

Pressure cooking significantly reduces braising time by trapping steam and increasing the internal pressure, which rapidly breaks down tough fibers in meats and vegetables. Combi-steam ovens offer precise temperature control and steam injection, allowing for more consistent moisture retention and better texture development during braising. While pressure cookers excel in speed, combi-steam ovens provide versatility and higher-quality results with slower, controlled cooking processes.

Table of Comparison

| Feature | Pressure Cooking | Combi-Steam Oven |

|---|---|---|

| Cooking Method | High-pressure steam in sealed pot | Combined steam and convection heat |

| Cooking Time | Fast (20-40 minutes) | Moderate (45-90 minutes) |

| Flavor Retention | High, seals in juices | Moderate, uses steam but less sealed |

| Texture Outcome | Tender, juicy braised meats | Evenly cooked, tender with slight caramelization |

| Energy Efficiency | Very efficient due to shorter cooking | Less efficient, longer cooking cycles |

| Ease of Use | Simple, requires monitoring pressure | Advanced controls, programmed settings |

| Cleaning | Easy, fewer parts | More complex, multiple components |

| Best For | Quick braising, stews, tender meats | Multi-step cooking, precise moisture control |

Introduction to Braising Methods

Braising methods combine moist and dry heat to tenderize tougher cuts of meat while preserving flavor through slow cooking. Pressure cooking uses sealed steam at high pressure to significantly reduce braising times compared to traditional methods.

Combi-steam ovens offer precise temperature and humidity control, allowing for consistent braising results with enhanced texture and moisture retention. Each method optimizes the cooking environment differently, impacting the tenderness and overall quality of braised dishes.

What Is Pressure Cooking?

Pressure cooking uses high-pressure steam to cook food faster by increasing the boiling point of water, which traps heat inside a sealed pot. This method is highly efficient for braising, as it tenderizes tough cuts of meat quickly while preserving moisture and flavor. Compared to a combi-steam oven, pressure cooking requires less time and energy, making it ideal for rapid braising without sacrificing texture.

Understanding Combi-Steam Ovens

Combi-steam ovens blend steam and convection heat, offering precise control over moisture and temperature for perfect braising results. This technology allows for gradual cooking that preserves texture and enhances flavor in meats and vegetables.

- Steam Injection - Injects controlled steam to maintain moisture during cooking, preventing drying out of braised dishes.

- Convection Heat - Circulates hot air to evenly cook food while forming a desirable crust or browning.

- Programmable Settings - Allows customization of temperature and humidity levels to tailor the braising process to specific recipes.

Understanding these features helps chefs achieve consistent, tender braised dishes using combi-steam ovens, contrasting the faster but different results from pressure cooking.

Speed and Efficiency Comparison

Pressure cooking significantly reduces braising time by using high steam pressure, often cooking dishes in one-third of the time required by combi-steam ovens. This method enhances energy efficiency by trapping heat and steam in a sealed environment, minimizing heat loss and reducing overall cooking energy consumption.

Combi-steam ovens offer versatility with precise temperature and humidity controls, allowing for consistent texture and flavor development during braising. However, they generally require longer cooking times compared to pressure cookers, which can impact kitchen throughput. For commercial kitchens aiming for speed and efficiency, pressure cookers present a substantial advantage, though combi-steam ovens excel in culinary control and quality.

Flavor Development and Texture

How does pressure cooking compare to a combi-steam oven for braising in terms of flavor development and texture? Pressure cooking intensifies flavors by trapping moisture and cooking food at high pressure, resulting in tender, juicy textures without drying out the meat. Combi-steam ovens use controlled steam and convection heat, preserving natural flavors and creating a more uniform texture with a delicate crust on braised dishes.

Nutrient Retention and Health Impacts

Pressure cooking preserves more vitamins and minerals due to shorter cooking times and reduced exposure to heat and water compared to combi-steam ovens. Combi-steam ovens offer gentle cooking with steam, maintaining texture but potentially causing slight nutrient loss through longer cooking periods.

- Pressure cooking enhances nutrient retention - High pressure shortens cooking time, limiting nutrient degradation in braised foods.

- Combi-steam ovens provide even cooking - Steam preserves moisture and texture but may reduce heat-sensitive vitamins due to longer exposure.

- Health impacts favor pressure cooking - Reduced nutrient loss contributes to higher antioxidant levels and better overall food quality.

Versatility in Braising Recipes

Pressure cooking offers rapid, high-pressure heat that excels at tenderizing tougher cuts of meat in braising recipes, significantly reducing cooking time. This method infuses flavors deeply while retaining moisture, ideal for stews and pot roasts.

Combi-steam ovens provide versatile braising options by combining steam and convection heat, allowing precise control over moisture levels and temperature. This results in evenly cooked dishes with a delicate texture, suitable for a wider range of ingredients such as vegetables and poultry.

Energy Consumption and Cost

Pressure cooking uses high pressure to cook food rapidly, significantly reducing energy consumption compared to combi-steam ovens that operate at lower pressures and longer cooking times. Combi-steam ovens typically consume more electricity due to prolonged steaming cycles and preheating phases. The lower energy use of pressure cookers translates into cost savings, making them more economical for braising tasks in both home and commercial kitchens.

Maintenance and Ease of Use

| Pressure Cooking Maintenance | Requires regular gasket and valve inspection to ensure sealing efficiency and safety; parts may need replacement over time due to wear from high pressure and temperature. |

| Combi-Steam Oven Maintenance | Involves periodic descaling and water filter changes to prevent mineral buildup; cleaning cycles are often automated, reducing manual effort and prolonging appliance lifespan. |

| Ease of Use Pressure Cooker | Offers rapid cooking with straightforward controls but demands careful pressure monitoring and release techniques, which can be challenging for beginners. |

| Ease of Use Combi-Steam Oven | Features programmable settings and touch controls for precise braising, ideal for user convenience and consistent results without extensive user intervention. |

Related Important Terms

Steam-infusion braising

Steam-infusion braising in pressure cooking achieves faster tenderization by combining high-pressure steam with intense heat, preserving moisture and flavor more efficiently than combi-steam ovens. Combi-steam ovens offer precise temperature control and gentle steam circulation, resulting in evenly cooked braised dishes but with longer cooking times compared to pressure cooking.

Pressurized steam burst

Pressure cooking uses a high-pressurized steam burst to rapidly break down tough fibers in braised dishes, significantly reducing cooking time compared to a combi-steam oven. While combi-steam ovens offer precise temperature control and moisture regulation, they lack the intense steam pressure that accelerates tenderness and flavor development during pressure cooking.

Multi-phase moisture cycling

Pressure cooking accelerates braising by sealing moisture and maintaining high steam pressure, ensuring rapid heat transfer and tender results, while multi-phase moisture cycling in combi-steam ovens alternates steam and dry heat to enhance flavor development and texture complexity; both methods optimize moisture control but differ in heat application dynamics and cooking duration.

Sous-pressure fusion

Sous-pressure fusion combines the rapid, high-pressure cooking of a pressure cooker with the precise steam control of a combi-steam oven, optimizing braising by preserving moisture and enhancing flavor infusion. This hybrid technique accelerates tenderization while maintaining the texture and nutritional quality superior to traditional methods, making it ideal for complex braised dishes.

Dual-thermal integration

Pressure cooking uses high-pressure steam to cook food rapidly by increasing the boiling point of water, allowing quicker braising with intense heat penetration. Combi-steam ovens combine convection heat and controlled steam injection, offering precise temperature and humidity control, which enhances the braising process through dual-thermal integration for tender and evenly cooked results.

Adaptive humidity control

Pressure cooking uses sealed, high-pressure steam to rapidly braise meats, locking in moisture and enhancing tenderness, while combi-steam ovens offer adaptive humidity control by precisely adjusting steam levels throughout the cooking cycle for consistent braising results. This adaptive humidity control in combi-steam ovens optimizes moisture retention and browning, providing greater flexibility and precision compared to the constant high-pressure environment of pressure cookers.

High-density braise pulse

Pressure cooking offers high-density braise pulses that rapidly tenderize tough cuts by maintaining intense steam pressure, resulting in deeply infused flavors and uniform texture. Combi-steam ovens provide controlled steam and convection heat but lack the concentrated pressure environment, making them less efficient for quick, high-intensity braising processes.

Smart-pressure regulation

Smart-pressure regulation in pressure cooking ensures precise control of steam levels and temperature, accelerating the braising process while preserving texture and flavor. In contrast, combi-steam ovens provide more gradual heat application with controlled humidity but less intense pressure, resulting in longer braising times and different moisture retention.

Steam-boosted tenderization

Pressure cooking uses high-pressure steam to rapidly break down connective tissues, resulting in faster, more efficient tenderization compared to a combi-steam oven. While combi-steam ovens offer precise temperature and humidity control for gradual braising, pressure cookers leverage steam-boosted cooking to achieve tender results in a fraction of the time.

Pressure cooking vs combi-steam oven for braising. Infographic

cookingdiff.com

cookingdiff.com