A pressure cooker and a pressure canner both use steam pressure to cook food quickly, but their designs and purposes differ significantly. Pressure cookers are ideal for fast cooking of meals, while pressure canners are specifically engineered to safely preserve low-acid foods by reaching higher pressures and maintaining precise temperature control to prevent bacterial contamination. Understanding these differences ensures safe and effective pressure-cooking tailored to your culinary needs.

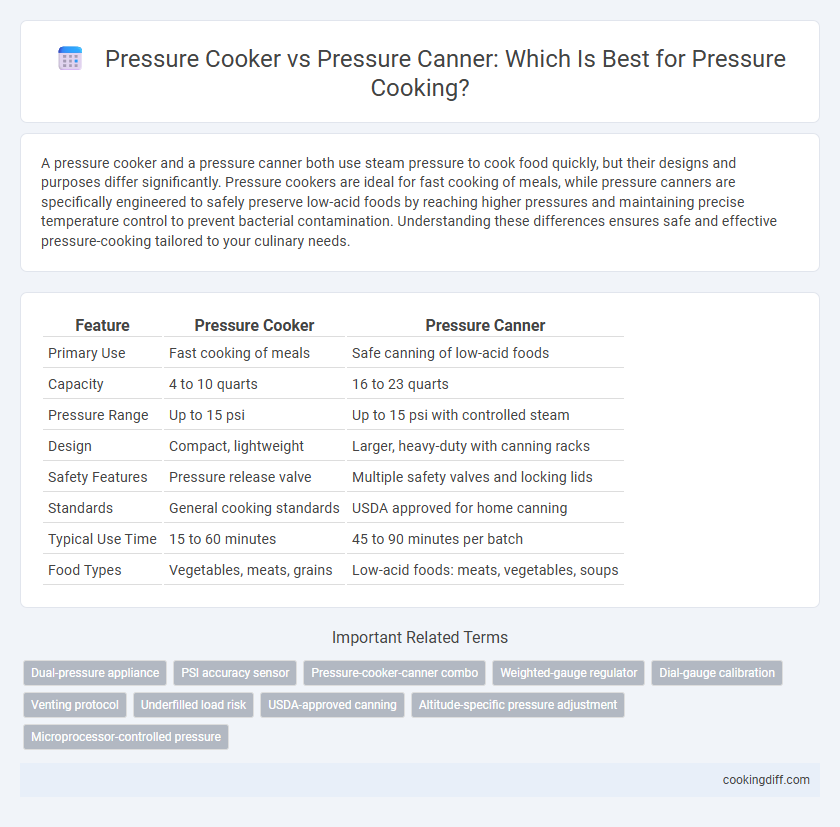

Table of Comparison

| Feature | Pressure Cooker | Pressure Canner |

|---|---|---|

| Primary Use | Fast cooking of meals | Safe canning of low-acid foods |

| Capacity | 4 to 10 quarts | 16 to 23 quarts |

| Pressure Range | Up to 15 psi | Up to 15 psi with controlled steam |

| Design | Compact, lightweight | Larger, heavy-duty with canning racks |

| Safety Features | Pressure release valve | Multiple safety valves and locking lids |

| Standards | General cooking standards | USDA approved for home canning |

| Typical Use Time | 15 to 60 minutes | 45 to 90 minutes per batch |

| Food Types | Vegetables, meats, grains | Low-acid foods: meats, vegetables, soups |

Understanding Pressure Cookers and Pressure Canners

What distinguishes a pressure cooker from a pressure canner in pressure-cooking applications? Pressure cookers are designed for rapid cooking of meals at high pressure, using temperatures typically around 240degF (116degC). Pressure canners, however, achieve and maintain higher pressures and temperatures, often reaching up to 250degF (121degC), essential for safely preserving low-acid foods in sealed jars during canning.

Key Differences Between Pressure Cookers and Canners

Pressure cookers and pressure canners both use steam under pressure but serve distinct purposes in the kitchen. Understanding their key differences is essential for safe and effective food preservation and cooking.

- Purpose - Pressure cookers are designed primarily for faster cooking of meals, while pressure canners are intended for safe home canning of low-acid foods.

- Size and Capacity - Pressure canners are larger to accommodate multiple jars and ensure even heat distribution during processing, whereas pressure cookers are smaller and focused on single-pot cooking.

- Pressure Control and Safety Features - Pressure canners maintain steady pressure levels for extended periods required in canning, with enhanced safety features to prevent underprocessing.

Choosing the appropriate device depends on whether the goal is quick cooking or safe food preservation through canning.

Safety Features: Pressure Cooker vs Pressure Canner

Pressure cookers and pressure canners both use high pressure to cook food efficiently, but pressure canners include enhanced safety features such as pressure gauges and locking lids to prevent opening under pressure, ensuring safe preservation of low-acid foods. Pressure cookers often have simpler safety mechanisms, like pressure release valves and overpressure plugs, suitable for everyday cooking but not designed for the rigorous demands of canning. When selecting between the two, understanding these safety distinctions is essential to prevent accidents and ensure food safety during pressure-based cooking or canning processes.

Pressure Cooking Functions: What Each Appliance Does

Pressure cookers are designed for quick meal preparation by using steam pressure to significantly reduce cooking time. Pressure canners, on the other hand, are engineered to safely preserve low-acid foods through high-pressure sterilization.

- Pressure Cooker Functionality - Utilizes high-pressure steam to cook food rapidly, optimizing texture and flavor in home cooking.

- Pressure Canner Functionality - Employs controlled high pressure and temperature to eliminate bacteria, ensuring safe long-term storage of canned foods.

- Key Difference - Pressure cookers focus on cooking speed, while pressure canners prioritize food safety in preservation processes.

Food Types: Suitable Uses for Cookers and Canners

Pressure cookers are ideal for quickly cooking foods like meats, vegetables, and grains, optimizing texture and flavor. Pressure canners are specifically designed to process low-acid foods such as meats, vegetables, and soups to ensure safe long-term preservation.

- Pressure cookers - Best for everyday meal preparation, reducing cooking times significantly.

- Pressure canners - Suitable for safely preserving low-acid foods in jars through high-temperature sterilization.

- Food types - Pressure cookers handle a wide variety of foods while pressure canners focus on safe home canning of acidic and low-acid foods.

Capacity and Size Comparisons

Pressure cookers typically range from 4 to 8 quarts, making them ideal for everyday cooking tasks and smaller batch meals. Pressure canners, designed for home canning, usually have a larger capacity of 16 to 23 quarts to accommodate multiple jars simultaneously. The size difference impacts cooking volume and heat distribution, with pressure canners requiring more stovetop space and higher heat input to maintain pressure.

Time Efficiency: Cooking vs Canning

Pressure cookers are designed for rapid cooking of meals, typically reducing cooking times by up to 70% compared to conventional methods. This makes them highly time-efficient for preparing everyday dishes quickly.

Pressure canners, while similar in appearance, are specifically engineered to reach and maintain the higher pressures necessary for safe canning of low-acid foods. Canning cycles in pressure canners are significantly longer, often taking an hour or more to ensure proper sterilization and preservation.

Cost Considerations and Long-Term Investment

| Pressure Cooker | Typically lower cost, ranging from $50 to $150, ideal for daily cooking tasks and small batch food preparation. Offers versatility but may require replacement more frequently due to wear, impacting long-term investment value. |

| Pressure Canner | Higher initial cost, often between $100 and $250, designed specifically for safe home canning with larger capacity. Durable construction provides a long-term investment for preserving large quantities, reducing future equipment expenses. |

Maintenance and Cleaning Tips

Pressure cookers require regular cleaning of the gasket and vent to maintain proper sealing and prevent food residue buildup. Pressure canners demand thorough cleaning of the lid, gasket, and pressure gauge to ensure safety and accurate pressure maintenance.

Both appliances benefit from inspecting the gasket for cracks or deformations and replacing it annually or as needed. Avoid submerging the pressure gauge in water; instead, wipe it clean to maintain its functionality. Proper drying of all components before storage prevents rust and extends the lifespan of the equipment.

Related Important Terms

Dual-pressure appliance

A dual-pressure appliance combines the features of a pressure cooker and a pressure canner, offering versatile cooking at both high and low pressures for pressure-cooking and safe food preservation. This dual functionality is ideal for canning acidic and low-acid foods while also enabling faster cooking times for stews, beans, and tougher cuts of meat.

PSI accuracy sensor

Pressure cookers typically operate at 10-15 PSI and rely on less precise pressure release valves, whereas pressure canners feature PSI accuracy sensors calibrated to maintain consistent pressure levels between 10-15 PSI for safe home canning. Accurate PSI monitoring in pressure canners ensures the destruction of harmful bacteria, such as Clostridium botulinum, which is critical for preserving food safety during pressure-cooking.

Pressure-cooker-canner combo

Pressure-cooker-canner combos offer versatile pressure-cooking capabilities, combining the compact size of pressure cookers with the higher pressure and large capacity required for safe home canning. These multi-use appliances optimize heat retention and pressure control, enabling efficient cooking and preserving of low-acid foods with USDA-recommended processing times.

Weighted-gauge regulator

A weighted-gauge regulator on a pressure cooker maintains consistent pressure by releasing steam at a preset level, ideal for cooking times and textures, while in pressure canners, it is critical for safely processing and preserving low-acid foods by ensuring precise pressure control. The weighted-gauge regulator's accuracy directly impacts the safety and effectiveness of pressure canning, preventing under or over-processing that could lead to food spoilage or health risks.

Dial-gauge calibration

Dial-gauge calibration is crucial for both pressure cookers and pressure canners to ensure accurate pressure levels during cooking and canning processes, preventing underprocessing or overprocessing. Pressure canners require more precise calibration and regular testing of the dial gauge compared to pressure cookers due to their use in safely preserving low-acid foods.

Venting protocol

Pressure cookers require a shorter venting time, typically around 10 minutes, to release steam before pressure builds, while pressure canners demand a longer venting period of 10 to 15 minutes to ensure all air is expelled for safe, even processing. Proper venting protocols in pressure canning prevent air pockets that can compromise vacuum seal integrity and food preservation.

Underfilled load risk

Pressure cookers underfilled with food risk uneven heating and potential damage due to excessive steam accumulation, while pressure canners require a full load to maintain consistent temperature and pressure for safe, effective sterilization. Underfilling a pressure canner compromises vacuum formation and heat distribution, increasing the risk of food spoilage or unsafe preservation.

USDA-approved canning

Pressure canners are specifically designed to reach the higher temperatures and maintain consistent pressure levels required for USDA-approved canning of low-acid foods, ensuring food safety by effectively eliminating harmful bacteria such as Clostridium botulinum. Pressure cookers, while similar in function for cooking, typically do not achieve or consistently maintain the necessary pressure and volume capacity for safe home canning, making them unsuitable for USDA-approved pressure canning processes.

Altitude-specific pressure adjustment

Pressure cookers and pressure canners both require altitude-specific pressure adjustments to ensure safe and efficient cooking, with pressure canners typically needing higher pressures to achieve proper food preservation at elevated altitudes. Accurate gauge calibration and adherence to recommended pressure settings are critical in preventing underprocessing or overprocessing when pressure-cooking at varying elevations.

Pressure cooker vs Pressure canner for pressure-cooking Infographic

cookingdiff.com

cookingdiff.com