Traditional pressure valves rely on gravity and steam pressure to regulate cooking pressure, offering a simple and reliable mechanism for pet food preparation. Spring valves use a spring to maintain consistent pressure, providing more precise control and faster pressure adjustments for pressure-cooking pet meals. Choosing between the two depends on the desired pressure stability and speed of cooking in pet food preparation.

Table of Comparison

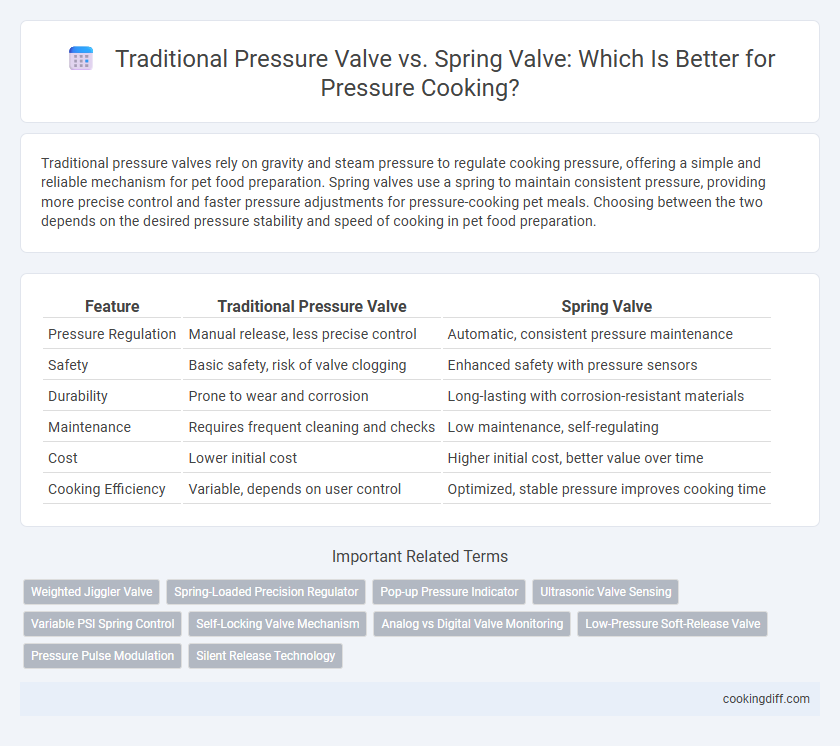

| Feature | Traditional Pressure Valve | Spring Valve |

|---|---|---|

| Pressure Regulation | Manual release, less precise control | Automatic, consistent pressure maintenance |

| Safety | Basic safety, risk of valve clogging | Enhanced safety with pressure sensors |

| Durability | Prone to wear and corrosion | Long-lasting with corrosion-resistant materials |

| Maintenance | Requires frequent cleaning and checks | Low maintenance, self-regulating |

| Cost | Lower initial cost | Higher initial cost, better value over time |

| Cooking Efficiency | Variable, depends on user control | Optimized, stable pressure improves cooking time |

Introduction: Understanding Pressure Cooker Valve Types

What are the key differences between traditional pressure valves and spring valves in pressure cookers? Traditional pressure valves rely on gravity and steam pressure to regulate cooking pressure, offering simplicity and durability. Spring valves use a metal spring mechanism to maintain consistent pressure, providing more precise control and enhanced safety features.

What is a Traditional Pressure Valve?

A traditional pressure valve in pressure cooking is a simple weight-based mechanism that regulates steam release by balancing pressure inside the pot. This valve maintains a consistent cooking pressure by lifting and dropping the weight, allowing excess steam to escape safely. Known for reliability, traditional pressure valves are commonly used in stovetop pressure cookers for their durability and ease of maintenance.

How Does a Spring Valve Work?

| Traditional Pressure Valve | Uses a weighted valve stack that releases steam once a set pressure is reached, maintaining consistent pressure inside the cooker. |

| Spring Valve | Operates using a spring mechanism that compresses under pressure, allowing precise control by adjusting the spring tension to maintain the desired steam pressure. |

| How Does a Spring Valve Work? | The spring valve compresses as internal pressure rises until force balances the spring tension, then steam is released to keep pressure steady, enabling more accurate pressure regulation compared to traditional weighted valves. |

Pressure Regulation: Comparing Both Valve Systems

Traditional pressure valves maintain pressure by releasing steam once a set threshold is reached, providing a straightforward pressure regulation method. Spring valves use a spring mechanism to adjust pressure release more precisely, allowing finer control within the cooking vessel.

Spring valve systems tend to offer more consistent pressure maintenance, reducing the risk of overpressure and enhancing cooking accuracy. Traditional valves may experience slight pressure fluctuations due to direct steam release, potentially impacting cooking times and results.

Safety Features: Traditional vs. Spring Valve

Traditional pressure valves in pressure cookers rely on weighted mechanisms to regulate internal pressure, offering a straightforward and reliable safety feature by releasing excess steam when pressure surpasses safe levels. These valves require manual adjustment and monitoring to maintain optimal pressure during cooking.

Spring valves use a spring-loaded mechanism that automatically adjusts to pressure changes, providing enhanced safety by maintaining consistent pressure without manual intervention. The responsive design of spring valves reduces the risk of pressure-related accidents by quickly releasing steam when necessary.

Cooking Performance and Consistency

Traditional pressure valves often provide less precise pressure regulation, leading to slight variations in cooking times and texture. Spring valves maintain consistent pressure levels, ensuring uniform cooking performance and reducing the risk of food overcooking or undercooking.

- Pressure Stability - Spring valves offer better pressure stability for consistent cooking results.

- Cooking Time Accuracy - Traditional valves may cause fluctuating cooking times due to variable pressure release.

- Food Texture Consistency - Spring valves help achieve uniform texture by maintaining steady internal pressure.

Maintenance and Durability of Valves

Traditional pressure valves often require more frequent cleaning due to their simpler mechanical design, which can accumulate food residues and affect performance. Spring valves typically offer enhanced durability with fewer maintenance needs, thanks to their enclosed spring mechanism that resists clogging and wear.

- Cleaning frequency - Traditional valves need regular manual cleaning to maintain optimal sealing and pressure levels.

- Durability - Spring valves are generally more robust, providing longer service life under high-temperature conditions.

- Maintenance complexity - Spring valves involve more complex internal parts but reduce overall maintenance time and effort.

User Experience: Noise and Ease of Use

The traditional pressure valve produces a distinct hissing noise that signals pressure release, which some users find reassuring but others may find disruptive in quiet kitchens. Spring valves operate more quietly with a smooth pressure regulation mechanism, enhancing user comfort during cooking. Ease of use is often higher with spring valves, as they typically require less manual adjustment and provide consistent performance.

Cost and Availability Comparison

Traditional pressure valves are generally more affordable and widely available due to their long-standing use in pressure-cooking appliances. Spring valves tend to be more expensive and less common, often found in premium or newer models.

Cost differences arise from the simpler design and manufacturing process of traditional valves compared to the more complex spring mechanism. Availability of traditional valves is higher with numerous replacement parts accessible in most markets. Spring valves require specialized components, making replacements costlier and less accessible in local stores.

Related Important Terms

Weighted Jiggler Valve

Weighted jiggler valves in traditional pressure cookers regulate steam release through a heavy, movable weight that jiggles to maintain consistent pressure, offering simple visual feedback on pressure status. Unlike spring valves that rely on internal coil springs to control pressure, weighted jiggler valves are highly durable and less prone to mechanical failure, making them favored for their reliability in long-term pressure-cooking applications.

Spring-Loaded Precision Regulator

Spring-loaded precision regulators in pressure cookers provide consistent steam release, maintaining accurate pressure levels for even cooking. Unlike traditional pressure valves, these regulators enhance safety and cooking efficiency by automatically adjusting to pressure fluctuations.

Pop-up Pressure Indicator

The pop-up pressure indicator in traditional pressure valves provides a simple visual cue when the cooker reaches the desired pressure, relying on steam pressure to lift the indicator. Spring valves, however, integrate a more precise spring-loaded mechanism that maintains consistent pressure levels and offers enhanced safety by regulating pressure more accurately during cooking.

Ultrasonic Valve Sensing

Traditional pressure valves rely on mechanical springs to regulate pressure during cooking, which can have slower response times and less precise control. Ultrasonic valve sensing technology offers faster, more accurate detection of pressure changes by using high-frequency sound waves, improving safety and cooking efficiency in pressure-cooking.

Variable PSI Spring Control

Variable PSI spring control in spring valves offers precise pressure regulation by adjusting the spring tension, enabling consistent cooking results across different recipes. Traditional pressure valves rely on fixed pressure levels, limiting flexibility and often causing fluctuations that affect texture and cooking time.

Self-Locking Valve Mechanism

Traditional pressure valves rely on gravity or basic locking systems that can sometimes release pressure unpredictably, whereas spring valves incorporate a self-locking valve mechanism ensuring consistent, secure sealing during pressure-cooking. The self-locking valve in spring valve systems responds dynamically to internal pressure changes, enhancing safety and maintaining optimal cooking conditions without manual intervention.

Analog vs Digital Valve Monitoring

Traditional pressure valves rely on analog mechanisms to regulate and release steam, offering tactile feedback but limited precision in pressure control. Digital valves integrate electronic sensors and microprocessors for real-time monitoring and automatic adjustments, enhancing safety and cooking accuracy in pressure-cooking applications.

Low-Pressure Soft-Release Valve

The low-pressure soft-release valve, often featured in spring valve pressure cookers, allows gradual steam release to prevent food overcooking and reduce the risk of sudden depressurization. In contrast, traditional pressure valves rely on a fixed pressure threshold, releasing steam abruptly, which can affect cooking precision and safety.

Pressure Pulse Modulation

Traditional pressure valves maintain cooking pressure through a fixed release mechanism, resulting in steady but less responsive pressure control. Spring valves utilize Pressure Pulse Modulation to dynamically adjust pressure by rapidly opening and closing, enhancing precision and reducing cooking time.

Traditional pressure valve vs spring valve for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com