Pressure release methods significantly impact flavor retention in pressure cooking. Quick pressure release can cause the abrupt loss of volatile aroma compounds, resulting in less intense flavors. Natural release allows the pressure to drop gradually, preserving delicate flavors and enhancing the overall taste of the dish.

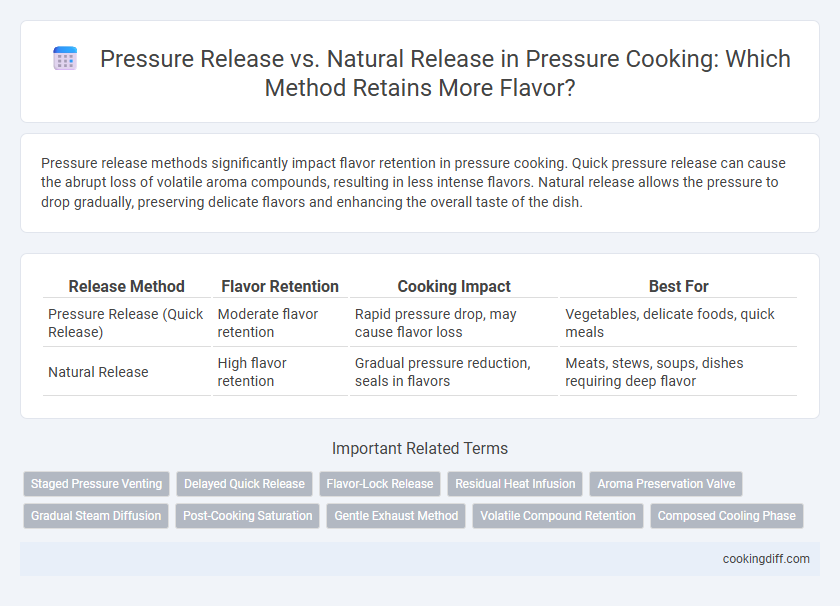

Table of Comparison

| Release Method | Flavor Retention | Cooking Impact | Best For |

|---|---|---|---|

| Pressure Release (Quick Release) | Moderate flavor retention | Rapid pressure drop, may cause flavor loss | Vegetables, delicate foods, quick meals |

| Natural Release | High flavor retention | Gradual pressure reduction, seals in flavors | Meats, stews, soups, dishes requiring deep flavor |

Understanding Pressure Release and Natural Release

Pressure release rapidly reduces internal pressure, stopping the cooking process quickly but may cause flavor loss due to sudden moisture evaporation. Natural release allows pressure to drop gradually, preserving delicate flavors by retaining steam and moisture within the food.

Understanding pressure release involves recognizing its impact on texture and taste, often preferred for quick-cooking items. Natural release enhances flavor retention in dense or slow-cooked dishes by maintaining a controlled environment until the pressure subsides naturally.

How Pressure Release Methods Impact Flavor

Pressure release methods significantly impact the flavor retention of pressure-cooked meals. Quick pressure release expels steam rapidly, which can cause some subtle aromas and volatile compounds to dissipate, potentially reducing flavor intensity.

Natural pressure release allows steam to escape gradually, preserving essential oils and enhancing the depth of taste in dishes like stews and braised meats. This slower method helps maintain moisture and locks in robust flavors by preventing sudden temperature drops.

Science Behind Flavor Retention in Pressure Cooking

Pressure release methods impact the retention of volatile flavor compounds in pressure-cooked foods by controlling the rate of steam and temperature drop. Natural release allows gradual pressure reduction, minimizing the loss of aromatic molecules, while quick pressure release causes rapid depressurization that can expel these volatile compounds. Studies indicate that slow pressure release preserves essential oils and enhances overall flavor intensity in dishes prepared with a pressure cooker.

Comparing Quick Release and Natural Release Techniques

Quick release expels steam rapidly, preserving the bright, fresh notes in delicate ingredients like vegetables, while natural release allows gradual pressure decrease, enhancing deep, complex flavors in meats and stews. Choosing the right pressure release method significantly impacts texture and taste, with natural release supporting better flavor melding and moisture retention.

- Quick Release - Immediately releases pressure to prevent overcooking and maintain vibrant flavors.

- Natural Release - Allows gradual pressure drop for continued cooking and enhanced flavor development.

- Flavor Retention - Natural release generally retains more juices and intensifies taste, especially in long-cooked dishes.

Adapting pressure release techniques based on the dish type optimizes flavor and texture outcomes.

Evaporation and Aroma Loss During Pressure Release

Rapid pressure release causes sudden evaporation, leading to significant aroma loss in pressure-cooked dishes. Natural release allows gradual pressure reduction, preserving volatile flavor compounds more effectively.

- Rapid pressure release increases evaporation - The sudden drop in pressure forces steam and volatile flavor molecules out of the pot quickly.

- Natural release minimizes aroma loss - Gradual pressure decrease retains essential oils and aromatic compounds within the food.

- Flavor retention depends on release method - Choosing natural release enhances taste profiles by reducing aroma dissipation during cooking.

When to Use Quick Release for Maximum Flavor

Quick release is ideal for pressure-cooked dishes where locking in fresh, vibrant flavors is critical, such as vegetables and seafood. It rapidly stops the cooking process, preserving delicate aromas and textures that can be lost during prolonged natural release.

- Preserves Freshness - Quick release immediately reduces pressure to maintain the bright, natural flavors of light ingredients.

- Prevents Overcooking - Using quick release avoids the gradual heat exposure that can dull flavor intensity and texture.

- Enhances Aroma Retention - Rapid pressure drops minimize evaporation of volatile flavor compounds for more aromatic results.

Benefits of Natural Release for Delicate Dishes

| Natural release allows gradual pressure reduction, preserving delicate textures and enhancing flavor retention in dishes like seafood, poultry, and custards. This method prevents sudden temperature and moisture changes, reducing the risk of overcooking and flavor loss. Benefits include improved taste, juiciness, and a more tender bite, essential for sensitive ingredients. |

Effect on Texture and Moisture Retention

Pressure release methods directly impact texture and moisture retention in pressure-cooked foods, with natural release allowing gradual cooling and better moisture absorption. Rapid pressure release can cause tougher textures and moisture loss as steam escapes quickly. Natural release preserves tenderness and juiciness, especially in meats and stews, by maintaining internal moisture balance.

Tips for Choosing the Best Release Method

Choosing between pressure release and natural release methods significantly impacts flavor retention in pressure-cooked meals. Fast pressure release can preserve texture but may cause flavors to dissipate quickly.

Natural release allows steam to condense gradually, enhancing the melding of spices and ingredients for richer taste. For dense or slow-cooked dishes like stews and braises, natural release is preferable to maintain depth of flavor. Use quick release for delicate ingredients to avoid overcooking while sacrificing some flavor intensity.

Related Important Terms

Staged Pressure Venting

Staged pressure venting balances pressure release and natural release methods, enhancing flavor retention by gradually reducing pressure to preserve volatile aromatics and maintain texture. This technique prevents sudden pressure drops that can cause moisture loss, ensuring superior taste and tenderness in pressure-cooked dishes.

Delayed Quick Release

Delayed Quick Release in pressure cooking involves a brief natural release period before finishing with a quick release, optimizing flavor retention by allowing juices to redistribute while preventing overcooking. This method balances pressure and heat reduction, enhancing the depth and complexity of flavors in meats and stews.

Flavor-Lock Release

Pressure-Lock Release technology enhances flavor retention by gradually releasing steam, allowing the ingredients to finish cooking in their own juices and preserve maximum aroma and taste. Unlike traditional quick pressure release, which can cause flavor loss and dryness, natural release combined with Pressure-Lock seals in rich, concentrated flavors for superior culinary results.

Residual Heat Infusion

Natural release in pressure cooking allows residual heat infusion to gently continue cooking, preserving delicate flavors and enhancing overall taste complexity compared to immediate pressure release which may cause abrupt temperature drops, leading to flavor loss. Residual heat infusion promotes gradual flavor melding and moisture retention, ensuring optimal depth and richness in dishes such as stews and braised meats.

Aroma Preservation Valve

Pressure release methods directly impact aroma preservation in pressure cooking, with natural release allowing gradual pressure decrease that enhances flavor retention by preventing the loss of volatile aromatic compounds. The Aroma Preservation Valve, designed to control steam escape gently during natural release, optimizes flavor and aroma by minimizing rapid pressure drops that can dissipate essential oils and fragrances.

Gradual Steam Diffusion

Gradual steam diffusion during natural pressure release preserves volatile flavor compounds by minimizing sudden pressure drops, enhancing taste intensity. In contrast, quick pressure release can cause abrupt steam escape, leading to flavor loss and less aromatic dishes.

Post-Cooking Saturation

Pressure release methods significantly affect post-cooking saturation, with natural release allowing gradual depressurization that better retains volatile flavor compounds within the food. Rapid pressure release can cause abrupt evaporation of aromatics, resulting in diminished flavor intensity and less saturated taste profiles.

Gentle Exhaust Method

The gentle exhaust method for pressure release gradually reduces pressure, preserving volatile aromatics and enhancing flavor retention in pressure-cooked dishes. Compared to natural release, this approach minimizes nutrient loss and maintains texture while ensuring a balanced infusion of flavors.

Volatile Compound Retention

Pressure release methods significantly impact volatile compound retention, with natural release better preserving delicate aromatics and flavors by preventing rapid depressurization that can cause volatile loss. Studies show natural release maintains higher concentrations of essential oils and volatile compounds, enhancing overall flavor intensity compared to immediate pressure release.

Pressure release vs natural release for flavor retention. Infographic

cookingdiff.com

cookingdiff.com