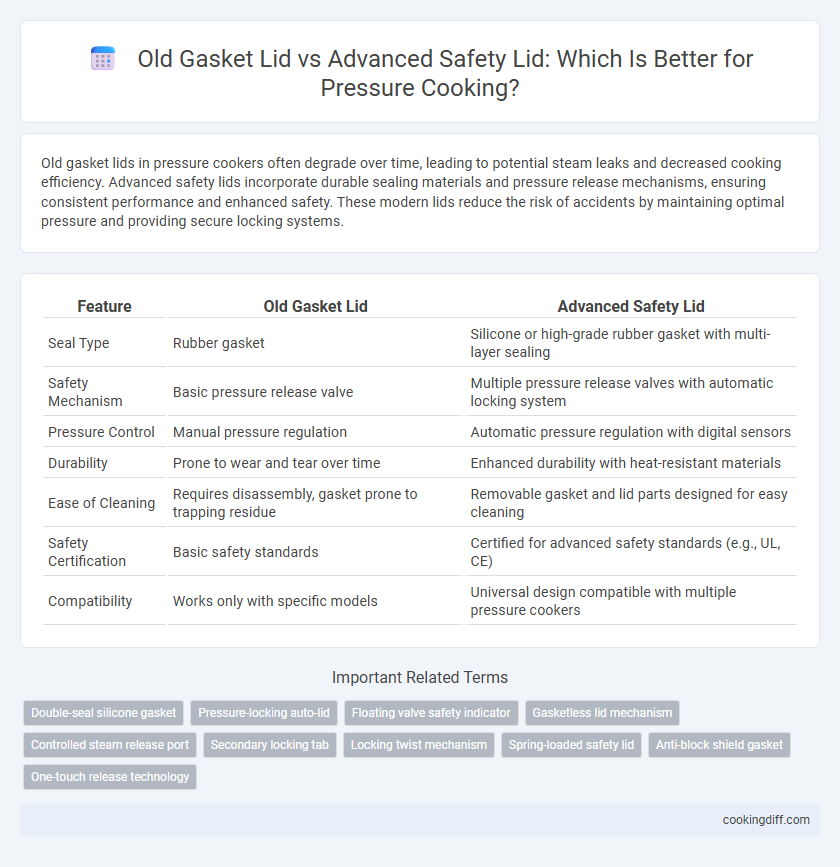

Old gasket lids in pressure cookers often degrade over time, leading to potential steam leaks and decreased cooking efficiency. Advanced safety lids incorporate durable sealing materials and pressure release mechanisms, ensuring consistent performance and enhanced safety. These modern lids reduce the risk of accidents by maintaining optimal pressure and providing secure locking systems.

Table of Comparison

| Feature | Old Gasket Lid | Advanced Safety Lid |

|---|---|---|

| Seal Type | Rubber gasket | Silicone or high-grade rubber gasket with multi-layer sealing |

| Safety Mechanism | Basic pressure release valve | Multiple pressure release valves with automatic locking system |

| Pressure Control | Manual pressure regulation | Automatic pressure regulation with digital sensors |

| Durability | Prone to wear and tear over time | Enhanced durability with heat-resistant materials |

| Ease of Cleaning | Requires disassembly, gasket prone to trapping residue | Removable gasket and lid parts designed for easy cleaning |

| Safety Certification | Basic safety standards | Certified for advanced safety standards (e.g., UL, CE) |

| Compatibility | Works only with specific models | Universal design compatible with multiple pressure cookers |

Introduction: Evolution of Pressure Cooker Lids

Pressure cooker lids have evolved significantly from traditional gasket designs to advanced safety mechanisms, enhancing cooking efficiency and user security. This evolution reflects improvements in materials, sealing technology, and integrated safety features.

- Old Gasket Lid - Utilizes a rubber gasket for sealing steam, requiring manual alignment and frequent replacement due to wear.

- Advanced Safety Lid - Incorporates multiple safety valves and locking systems to prevent accidental opening under pressure, ensuring enhanced protection.

- Material and Design Improvements - Transition from simple metal and rubber components to durable, heat-resistant materials that improve durability and seal integrity.

Construction Material: Old Gasket Lid vs Advanced Safety Lid

The old gasket lid is typically made from basic silicone or rubber materials that offer adequate sealing but can degrade quickly under high heat and pressure. These materials may lose flexibility over time, increasing the risk of steam leaks during cooking.

In contrast, the advanced safety lid uses high-grade silicone combined with reinforced stainless steel or polymer composites, enhancing durability and heat resistance. This innovative construction ensures a more reliable seal and significantly improves pressure retention and overall safety in modern pressure cookers.

Sealing Mechanism: Traditional vs Modern Approaches

The old gasket lid relies on a rubber or silicone ring to create an airtight seal, which can wear out over time and compromise pressure retention. The advanced safety lid incorporates multiple sealing layers and pressure-sensitive locks to enhance durability and prevent accidental openings during cooking.

Traditional pressure cooker lids depend primarily on a single gasket for sealing, which requires regular maintenance and replacement to ensure safety. In contrast, modern lids use engineered seals combined with mechanical locking systems that not only improve pressure stability but also provide fail-safe mechanisms. These innovations significantly reduce the risk of steam leaks and overheating, making pressure cooking safer and more efficient.

Safety Features: What’s New in Advanced Lids?

Old gasket lids rely primarily on a simple rubber seal that can wear out or crack over time, increasing the risk of steam leaks and pressure loss. Advanced safety lids incorporate multi-layered silicone gaskets with enhanced durability and heat resistance, significantly reducing the chance of failure during cooking.

Modern lids also feature integrated locking mechanisms and pressure indicators that provide real-time feedback to ensure the cooker remains securely closed under pressure. These updated safety components prevent accidental openings and improve overall user protection compared to traditional gasket lids.

Pressure Regulation: Consistency and Reliability Compared

| Feature | Old Gasket Lid | Advanced Safety Lid |

|---|---|---|

| Pressure Regulation | Relies on manual sealing and basic rubber gaskets that can wear out, leading to inconsistent pressure levels and potential leaks during pressure-cooking. | Incorporates silicone or multi-layer gaskets with precise locking mechanisms, ensuring stable pressure maintenance and enhanced reliability for uniform cooking results. |

| Durability | Susceptible to deformation and cracking, often requiring frequent gasket replacement to maintain effective pressure control. | Constructed with resilient materials designed for long-term use, minimizing gasket deterioration and ensuring durable, airtight sealing over time. |

| Safety Features | Limited pressure release options increase risk of uncontrolled pressure buildup, requiring close monitoring during cooking. | Equipped with integrated pressure indicators and automatic release valves to prevent overpressure, enhancing user safety and operational consistency. |

Durability and Maintenance: Longevity of Each Lid Type

How does the longevity of old gasket lids compare to advanced safety lids in pressure cooking? Old gasket lids often require frequent replacements due to wear and tear on the rubber seal, impacting durability. Advanced safety lids feature more resilient materials and design improvements that extend their lifespan and reduce maintenance needs significantly.

User Experience: Ease of Use and Convenience

Old gasket lids in pressure cookers often require more effort to align and seal properly, which can lead to occasional steam leaks and user frustration. Advanced safety lids feature improved locking mechanisms and intuitive designs that simplify the sealing process, enhancing overall cooking convenience and safety.

- Alignment Precision - Advanced safety lids incorporate clear indicators to ensure correct placement, reducing error and stress during use.

- Sealing Reliability - Upgraded gaskets in modern lids create more consistent seals, preventing steam escape and improving cooking efficiency.

- Safety Features - Built-in pressure release valves and secure locks in advanced lids offer an added layer of user protection and peace of mind.

The enhanced usability of advanced safety lids significantly improves the pressure-cooking experience for both novice and experienced users.

Cooking Performance: Culinary Results Side-by-Side

Old gasket lids often suffer from pressure inconsistencies, leading to uneven cooking and variable texture in meals. Advanced safety lids feature improved sealing technology, ensuring stable pressure levels that enhance the flavor and tenderness of dishes. This results in more reliable, evenly cooked food with better retention of nutrients and moisture.

Compatibility with Modern Pressure Cookers

Old gasket lids often lack the precise sealing mechanisms required for modern pressure cookers, leading to potential safety hazards and inefficient cooking. Advanced safety lids are designed with compatibility in mind, ensuring a secure fit and enhanced performance across current pressure cooker models.

- Old gasket incompatibility - Older lids may not fit newer pressure cookers due to size and design changes in sealing surfaces.

- Enhanced sealing technology - Advanced safety lids feature improved gaskets that provide airtight seals tailored for modern cookers.

- Safety compliance - Safety lids meet current regulatory standards, reducing risks associated with pressure cooking failures.

Related Important Terms

Double-seal silicone gasket

The advanced safety lid for pressure cooking features a double-seal silicone gasket that enhances airtightness and prevents steam leaks, ensuring optimal pressure retention and safety. In contrast, the old gasket lid typically uses a single-seal design, which may compromise sealing efficiency and increase the risk of pressure loss during cooking.

Pressure-locking auto-lid

The pressure-locking auto-lid offers enhanced safety by securely sealing and automatically locking the pressure cooker lid, minimizing the risk of accidental opening during high-pressure cooking compared to traditional old gasket lids that rely on manual sealing and can wear out over time. Advanced safety lids also often include multiple safety mechanisms such as pressure sensors and release valves, ensuring consistent pressure maintenance and safer cooking performance.

Floating valve safety indicator

The advanced safety lid in pressure cookers features a floating valve safety indicator that provides a clear, visual cue when internal pressure is at a safe level to open, enhancing user safety and reducing accidental lid removal. In contrast, old gasket lids often lack this precise indicator, relying on less reliable pressure signals that may increase the risk of improper handling during cooking.

Gasketless lid mechanism

The advanced safety lid for pressure-cooking features a gasketless lid mechanism that eliminates the traditional rubber gasket, reducing maintenance and preventing common issues like wear and leakage. This innovation enhances durability and ensures a more reliable seal by utilizing precision-engineered locking systems and pressure sensors.

Controlled steam release port

Old gasket lids often lack a dedicated controlled steam release port, increasing the risk of sudden pressure bursts during cooking. Advanced safety lids feature integrated steam release mechanisms that regulate pressure more precisely, enhancing both cooking efficiency and user safety.

Secondary locking tab

Old gasket lids rely on basic sealing mechanisms without a secondary locking tab, increasing the risk of accidental lid release during pressure cooking. Advanced safety lids incorporate a secondary locking tab that securely locks the lid once pressure builds, enhancing user safety and preventing hazardous openings.

Locking twist mechanism

Old gasket lids rely on a basic rubber seal and simple locking mechanisms that may wear out quickly, while advanced safety lids feature reinforced locking twist mechanisms designed for secure closure and enhanced pressure retention. These modern lids improve cooker durability and user safety by preventing accidental opening under pressure through precise, multi-point locking systems.

Spring-loaded safety lid

The spring-loaded safety lid in advanced pressure cookers offers enhanced sealing and pressure regulation compared to the old gasket lid, minimizing the risk of steam leaks and lid blow-offs. Designed with integrated pressure release mechanisms, this lid type ensures safer cooking by automatically locking when the ideal pressure is reached and releasing excess steam efficiently.

Anti-block shield gasket

The advanced safety lid for pressure-cooking features an anti-block shield gasket designed to prevent food particles from clogging the vent, enhancing safety and maintaining optimal pressure levels. In contrast, the traditional old gasket lid lacks this specialized shield, increasing the risk of blockage and pressure buildup during cooking.

Old gasket lid vs Advanced safety lid for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com