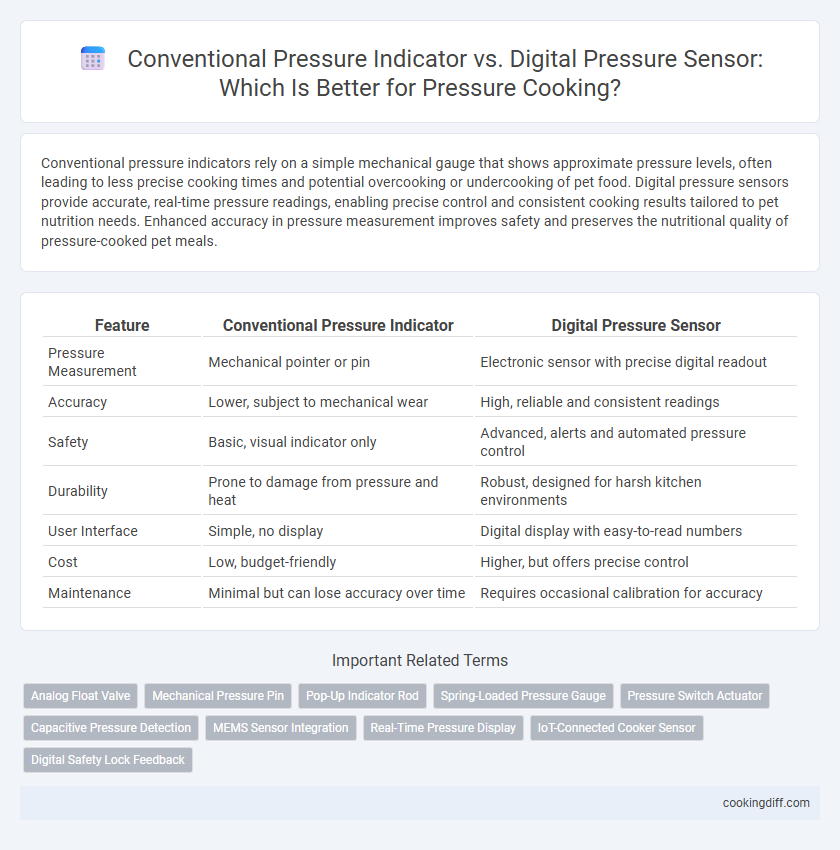

Conventional pressure indicators rely on a simple mechanical gauge that shows approximate pressure levels, often leading to less precise cooking times and potential overcooking or undercooking of pet food. Digital pressure sensors provide accurate, real-time pressure readings, enabling precise control and consistent cooking results tailored to pet nutrition needs. Enhanced accuracy in pressure measurement improves safety and preserves the nutritional quality of pressure-cooked pet meals.

Table of Comparison

| Feature | Conventional Pressure Indicator | Digital Pressure Sensor |

|---|---|---|

| Pressure Measurement | Mechanical pointer or pin | Electronic sensor with precise digital readout |

| Accuracy | Lower, subject to mechanical wear | High, reliable and consistent readings |

| Safety | Basic, visual indicator only | Advanced, alerts and automated pressure control |

| Durability | Prone to damage from pressure and heat | Robust, designed for harsh kitchen environments |

| User Interface | Simple, no display | Digital display with easy-to-read numbers |

| Cost | Low, budget-friendly | Higher, but offers precise control |

| Maintenance | Minimal but can lose accuracy over time | Requires occasional calibration for accuracy |

Introduction: Understanding Pressure Indicators in Modern Cooking

Conventional pressure indicators in pressure cookers provide a basic visual cue, usually a weighted valve or pop-up button, to signal when the optimal cooking pressure is reached. These mechanical indicators rely on steam pressure to physically move a part of the cooker, offering a simple but sometimes imprecise measurement.

Digital pressure sensors use electronic components to monitor pressure levels with high accuracy and provide real-time feedback on an LCD or LED display. This advanced technology allows for precise control over cooking conditions, enhancing safety and improving food quality in modern pressure cooking appliances.

Conventional Pressure Indicators: How They Work

Conventional pressure indicators in pressure cookers rely on a spring-loaded valve or weighted gauge that rises or moves to signal the pressure level inside the pot. These mechanical devices provide a simple, visual cue but lack precise pressure readings compared to digital sensors. Their design allows users to monitor pressure through physical movement relevant to the internal steam pressure, ensuring safety without the need for electronic components.

Digital Pressure Sensors: Advanced Technology Explained

Digital pressure sensors in pressure-cooking use advanced MEMS technology to provide precise and real-time pressure readings. These sensors offer higher accuracy compared to conventional pressure indicators, enabling better control over cooking conditions.

Unlike traditional mechanical indicators that rely on visible markers, digital sensors deliver continuous electronic feedback, facilitating smarter pressure regulation. Integration with smart kitchen appliances allows for automated adjustments, enhancing safety and cooking efficiency. Their ability to detect minute pressure variations helps maintain optimal cooking times and textures, revolutionizing pressure-cooking performance.

Accuracy: Conventional vs Digital Sensors

| Conventional Pressure Indicator | Relies on visual gauge with mechanical parts that may lag or show inconsistent readings under fluctuating pressure conditions. |

| Digital Pressure Sensor | Offers precise, real-time pressure monitoring with electronic accuracy, minimizing errors and enhancing cooking consistency in pressure-cooking. |

Safety Considerations Between Indicator Types

Conventional pressure indicators rely on mechanical parts that can wear out, potentially leading to inaccurate pressure readings and safety risks. Digital pressure sensors offer precise monitoring and alert systems that enhance safety by reducing the chance of overpressure incidents.

- Mechanical wear risk - Conventional indicators may degrade over time, compromising pressure accuracy.

- Real-time monitoring - Digital sensors provide continuous and exact pressure data for safer cooking.

- Automated alerts - Digital systems can trigger alarms or shutoffs to prevent accidents.

User Experience: Traditional vs Digital Control

How does user experience differ between conventional pressure indicators and digital pressure sensors in pressure-cooking? Conventional pressure indicators provide a tactile, visual cue but can lack precision in maintaining exact pressure levels. Digital pressure sensors offer accurate control and real-time feedback, enhancing safety and cooking consistency through precise pressure monitoring.

Maintenance and Durability Comparison

Conventional pressure indicators in pressure cookers require regular manual checks and are prone to wear from mechanical parts. Digital pressure sensors offer enhanced durability with minimal maintenance due to solid-state components and precise electronic monitoring.

- Maintenance Frequency - Conventional indicators need frequent cleaning and inspection to ensure accurate pressure readings.

- Durability - Digital sensors have a longer lifespan as they lack moving parts that commonly deteriorate over time.

- Reliability Under Stress - Digital sensors maintain consistent performance under high-pressure conditions, reducing risk of failure compared to mechanical indicators.

Cost Analysis: Which Pressure Indicator Is More Economical?

Conventional pressure indicators are generally more affordable upfront compared to digital pressure sensors, making them a cost-effective option for budget-conscious users. However, digital pressure sensors offer long-term savings through enhanced accuracy and reduced cooking errors, potentially lowering energy and ingredient waste.

- Initial Cost - Conventional indicators have a lower purchase price, making initial setup cheaper.

- Maintenance - Digital sensors require minimal maintenance, while conventional indicators may need regular calibration or replacement.

- Operational Efficiency - Digital sensors optimize cooking times and pressure levels, reducing resource consumption.

Considering both upfront and long-term expenses, digital pressure sensors can be more economical depending on usage frequency and precision needs.

Suitability for Home and Commercial Use

Conventional pressure indicators are reliable and straightforward, making them suitable for most home pressure cookers due to their ease of use and low cost. Digital pressure sensors provide precise pressure monitoring and control, ideal for commercial kitchens requiring consistent cooking results and enhanced safety features. Home users benefit from the simplicity of conventional indicators, while commercial settings leverage the advanced accuracy of digital pressure sensors for efficiency and scalability.

Related Important Terms

Analog Float Valve

The conventional analog float valve pressure indicator relies on mechanical movement to signal pressure levels, offering a straightforward and reliable visual cue for pressure-cooking safety. Unlike digital pressure sensors that provide precise electronic readings and enhanced accuracy, the analog float valve excels in durability and simplicity without requiring power sources or complex calibration.

Mechanical Pressure Pin

Mechanical pressure pins in conventional pressure indicators offer a simple visual cue for pressure levels in pressure-cooking, relying on physical displacement to signal when cooking pressure is reached. Digital pressure sensors provide precise, real-time pressure monitoring and accuracy but lack the mechanical reliability and straightforward feedback of a pressure pin.

Pop-Up Indicator Rod

The conventional pressure indicator with a pop-up indicator rod provides a simple, visual cue for pressure levels but lacks precise measurement, leading to potential inconsistencies in cooking results. In contrast, a digital pressure sensor offers accurate, real-time pressure data that enhances cooking precision and safety by continuously monitoring and adjusting the pressure inside the cooker.

Spring-Loaded Pressure Gauge

Spring-loaded pressure gauges in conventional pressure cookers use a weighted valve to release steam at a specific pressure, providing a visual and audible pressure indicator. Digital pressure sensors offer more precise pressure monitoring by electronically measuring internal pressure levels, allowing for better control and safety during pressure cooking.

Pressure Switch Actuator

Conventional pressure indicators in pressure cookers rely on mechanical pressure switch actuators that respond to steam pressure by physically moving a valve or rod, providing a simple and reliable pressure boundary control. Digital pressure sensors utilize electronic pressure switch actuators for precise real-time pressure monitoring and control, enhancing safety by automatically adjusting heat or releasing pressure based on sensor input.

Capacitive Pressure Detection

Conventional pressure indicators rely on mechanical gauges that measure pressure through physical displacement, often resulting in less precise readings and slower response times. Digital pressure sensors using capacitive pressure detection offer higher accuracy and faster response by converting pressure changes into electrical signals, enhancing safety and cooking control in pressure-cooking appliances.

MEMS Sensor Integration

Conventional pressure indicators rely on mechanical components that provide basic pressure readings, whereas digital pressure sensors with MEMS sensor integration offer precise, real-time monitoring and enhanced accuracy in pressure-cooking. MEMS technology enables compact, reliable sensors that improve safety and cooking consistency by delivering continuous digital feedback within pressure cookers.

Real-Time Pressure Display

Digital pressure sensors offer a precise real-time pressure display during pressure cooking, enabling better control and safety compared to conventional pressure indicators that rely on basic mechanical signals. The continuous electronic monitoring of digital sensors ensures accurate pressure readings, reducing the risk of overcooking or undercooking.

IoT-Connected Cooker Sensor

Conventional pressure indicators rely on mechanical gauges that provide basic pressure readings but lack real-time data connectivity and precise monitoring capabilities. Digital pressure sensors integrated into IoT-connected cookers enable continuous, accurate pressure tracking with remote monitoring and automated adjustments, enhancing safety and cooking efficiency through smart technology.

Conventional pressure indicator vs Digital pressure sensor for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com