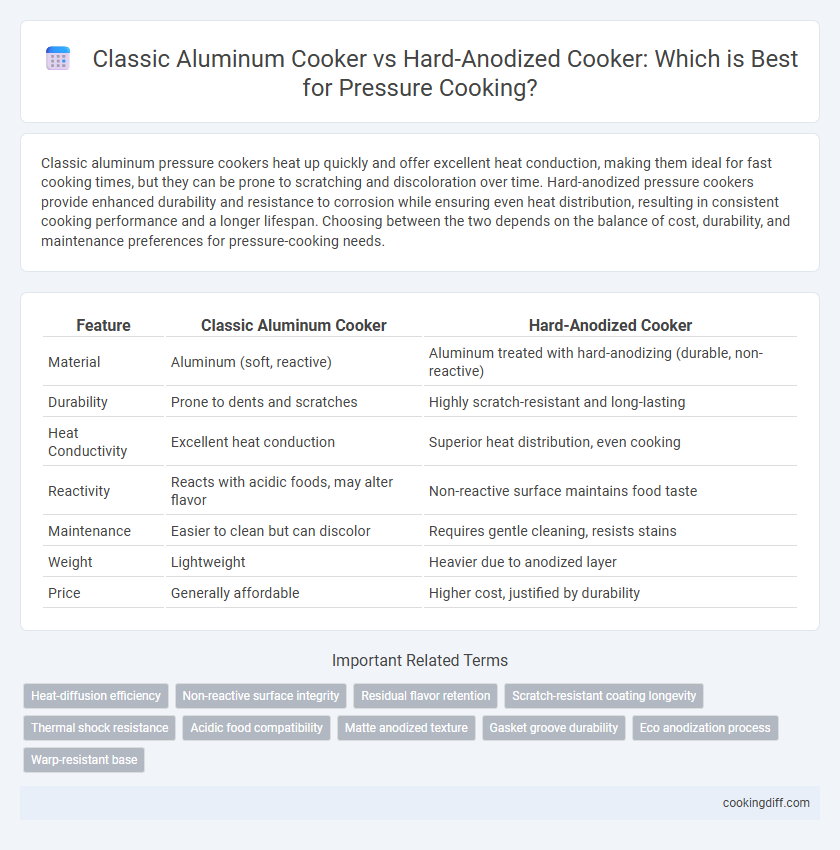

Classic aluminum pressure cookers heat up quickly and offer excellent heat conduction, making them ideal for fast cooking times, but they can be prone to scratching and discoloration over time. Hard-anodized pressure cookers provide enhanced durability and resistance to corrosion while ensuring even heat distribution, resulting in consistent cooking performance and a longer lifespan. Choosing between the two depends on the balance of cost, durability, and maintenance preferences for pressure-cooking needs.

Table of Comparison

| Feature | Classic Aluminum Cooker | Hard-Anodized Cooker |

|---|---|---|

| Material | Aluminum (soft, reactive) | Aluminum treated with hard-anodizing (durable, non-reactive) |

| Durability | Prone to dents and scratches | Highly scratch-resistant and long-lasting |

| Heat Conductivity | Excellent heat conduction | Superior heat distribution, even cooking |

| Reactivity | Reacts with acidic foods, may alter flavor | Non-reactive surface maintains food taste |

| Maintenance | Easier to clean but can discolor | Requires gentle cleaning, resists stains |

| Weight | Lightweight | Heavier due to anodized layer |

| Price | Generally affordable | Higher cost, justified by durability |

Introduction to Pressure Cooking: Aluminum vs Hard-Anodized

Pressure cooking significantly reduces cooking time by using steam pressure to raise the boiling point of water. Classic aluminum cookers and hard-anodized cookers are two popular types used in this method, each offering distinct benefits.

- Classic Aluminum Cooker - Lightweight and excellent at conducting heat quickly, providing even cooking.

- Hard-Anodized Cooker - Features a durable, non-reactive surface that resists corrosion and scratches for long-lasting use.

- Heat Conductivity - Aluminum cookers heat faster than hard-anodized but may require more careful handling to prevent damage.

Choosing between aluminum and hard-anodized pressure cookers depends on priorities such as durability, heat conduction, and maintenance preferences.

Material Composition: How Aluminum and Hard-Anodized Cookers Differ

| Material Composition | Classic Aluminum Cooker | Hard-Anodized Cooker |

|---|---|---|

| Base Material | Raw aluminum, lightweight and highly conductive | Aluminum treated through hard-anodization process for enhanced durability |

| Surface Coating | Uncoated or lightly coated, prone to scratches and oxidation | Hard, non-reactive anodized layer resists corrosion and abrasion |

| Heat Distribution | Excellent thermal conductivity but uneven heat retention | Improved heat retention and uniform distribution due to anodized surface |

| Durability | Less scratch-resistant, potential to warp under high heat | Highly durable and warp-resistant under temperature stress |

Heat Conductivity and Cooking Efficiency

Classic aluminum pressure cookers feature excellent heat conductivity, allowing rapid and even heat distribution that enhances cooking efficiency. Their lightweight structure enables quick temperature adjustments, reducing overall cooking time.

Hard-anodized pressure cookers offer superior durability with enhanced heat retention, promoting consistent cooking temperatures and energy savings. Although heat conductivity is slightly lower than aluminum, their non-reactive surface ensures better cooking performance for acidic foods.

Durability and Longevity Comparison

Which pressure cooker offers better durability and longevity: classic aluminum or hard-anodized? Hard-anodized cookers feature a dense, non-reactive surface that resists scratches and corrosion, extending their lifespan significantly compared to classic aluminum models. While aluminum cookers heat quickly, they are prone to dents and wear, resulting in shorter durability under frequent pressure-cooking use.

Safety Features: Classic Aluminum vs Hard-Anodized Cookers

Hard-anodized pressure cookers offer enhanced safety features compared to classic aluminum models due to their durable, non-reactive surface and resistance to corrosion. Classic aluminum cookers are lightweight but may wear down faster, increasing the risk of pressure leaks over time.

- Material Durability - Hard-anodized cookers provide a stronger, scratch-resistant surface that maintains integrity under high pressure.

- Corrosion Resistance - The non-porous hard-anodized finish prevents corrosion, reducing wear and potential failure points.

- Pressure Sealing - Classic aluminum cookers may degrade more quickly, compromising gasket seals and increasing pressure-related hazards.

Maintenance and Cleaning Requirements

Classic aluminum cookers require frequent seasoning and careful drying to prevent oxidation and discoloration, while hard-anodized cookers offer a more durable, non-porous surface that resists corrosion and staining. Maintenance for hard-anodized options is generally easier, as they typically clean well with mild detergents without special treatments.

- Classic Aluminum Maintenance - Needs regular seasoning to maintain its protective layer and avoid rusting.

- Hard-Anodized Durability - Features a tougher surface that withstands scrubbing and resists corrosion better than aluminum.

- Cleaning Ease - Hard-anodized pressure cookers clean effortlessly with standard dish soap, unlike aluminum which requires gentle handling.

Cooking Performance: Taste, Texture, and Nutrition

Classic aluminum pressure cookers provide rapid heat conduction that ensures evenly cooked meals, preserving natural flavors and nutrients effectively. Hard-anodized pressure cookers, with their non-reactive surface, enhance the texture by preventing food from sticking and improving browning for richer taste profiles. Both materials maintain vitamins and minerals well, but hard-anodized cookware offers superior durability and a slightly better retention of food texture under high-pressure cooking conditions.

Price Differences and Value for Money

Classic aluminum pressure cookers are generally more affordable, offering budget-friendly options for everyday cooking, while hard-anodized cookers come at a higher price due to their enhanced durability and corrosion resistance. The hard-anodized models provide better heat distribution and longevity, which justifies their premium cost for frequent users seeking long-term value. For occasional use, aluminum cookers deliver satisfactory performance at minimal expense, but those prioritizing durability may find the investment in hard-anodized cookers more cost-effective over time.

Compatibility with Modern Cooktops

Classic aluminum pressure cookers provide excellent heat conduction but may not be suitable for induction cooktops due to their non-magnetic nature. Hard-anodized pressure cookers feature a layered aluminum core with a magnetic stainless steel base, ensuring broad compatibility with induction, gas, and electric cooktops.

While classic aluminum cookers excel in even heat distribution, their use is typically limited to gas and electric coil stoves. Hard-anodized models offer superior durability with a non-reactive surface and enhanced resistance to scratches and corrosion. Their reinforced bases guarantee stability and efficient performance on modern induction cooktops, making them a versatile choice for contemporary kitchens.

Related Important Terms

Heat-diffusion efficiency

Classic aluminum pressure cookers excel in heat diffusion due to aluminum's high thermal conductivity, allowing rapid and even heating. Hard-anodized pressure cookers, while more durable and resistant to corrosion, have slightly lower thermal conductivity, resulting in less efficient heat diffusion compared to classic aluminum models.

Non-reactive surface integrity

Hard-anodized pressure cookers feature a non-reactive surface that prevents food from interacting with the metal, preserving flavor and preventing discoloration, unlike classic aluminum cookers which can react with acidic ingredients. This non-reactive quality enhances durability and maintains the cooker's integrity over time, making hard-anodized models ideal for consistent pressure-cooking performance.

Residual flavor retention

Classic aluminum pressure cookers tend to retain more residual flavors from previous meals due to their porous surface, potentially affecting the taste of subsequent dishes. Hard-anodized pressure cookers feature a non-porous, smooth surface that minimizes flavor retention, ensuring cleaner taste profiles with each use.

Scratch-resistant coating longevity

Classic aluminum pressure cookers offer rapid heat conduction but are prone to scratches that can compromise their surface integrity over time, reducing cookware lifespan. Hard-anodized pressure cookers feature a durable, scratch-resistant coating that enhances longevity by preventing wear and maintaining non-stick performance under frequent pressure-cooking conditions.

Thermal shock resistance

Classic aluminum pressure cookers offer excellent heat conductivity but are more prone to thermal shock, increasing the risk of warping or cracking under sudden temperature changes. Hard-anodized pressure cookers provide superior thermal shock resistance due to their durable oxide layer, ensuring greater structural integrity and longevity during rapid heating and cooling cycles.

Acidic food compatibility

Classic aluminum pressure cookers react with acidic foods, leading to metallic taste and potential discoloration, whereas hard-anodized pressure cookers have a non-reactive surface that ensures safe cooking of tomatoes, citrus, and other acidic ingredients without affecting flavor or appearance. The hard-anodized construction provides enhanced corrosion resistance, making it ideal for pressure-cooking acidic dishes with durability and food safety.

Matte anodized texture

Classic aluminum pressure cookers offer excellent heat conductivity and affordability, but often lack durability and develop scratches easily. Hard-anodized pressure cookers feature a matte anodized texture that provides enhanced surface hardness, corrosion resistance, and non-reactive qualities, making them ideal for long-lasting, efficient pressure-cooking performance.

Gasket groove durability

Classic aluminum pressure cookers typically feature a softer gasket groove that may wear out faster under high pressure and frequent use, impacting the seal integrity over time. Hard-anodized pressure cookers offer enhanced gasket groove durability through a tougher, corrosion-resistant surface that maintains a reliable seal and extends the lifespan of the gasket system.

Eco anodization process

Hard-anodized pressure cookers, produced through the eco anodization process, offer superior corrosion resistance and enhanced durability compared to classic aluminum cookers, which are prone to wear and reactive with acidic foods. The eco anodization method creates a non-toxic, environmentally friendly oxide layer that improves heat distribution and ensures safer, longer-lasting performance in pressure-cooking applications.

Classic aluminum cooker vs hard-anodized cooker for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com