Weighted valves in pressure cookers maintain consistent pressure by using a heavy weight that balances steam release, ensuring precise cooking without frequent adjustments. Spring valves rely on a spring mechanism to regulate pressure, offering faster response but sometimes less stability under fluctuating heat. Choosing between weighted and spring valves depends on cooking preferences, with weighted valves favoring steady pressure and spring valves providing quicker pressure changes.

Table of Comparison

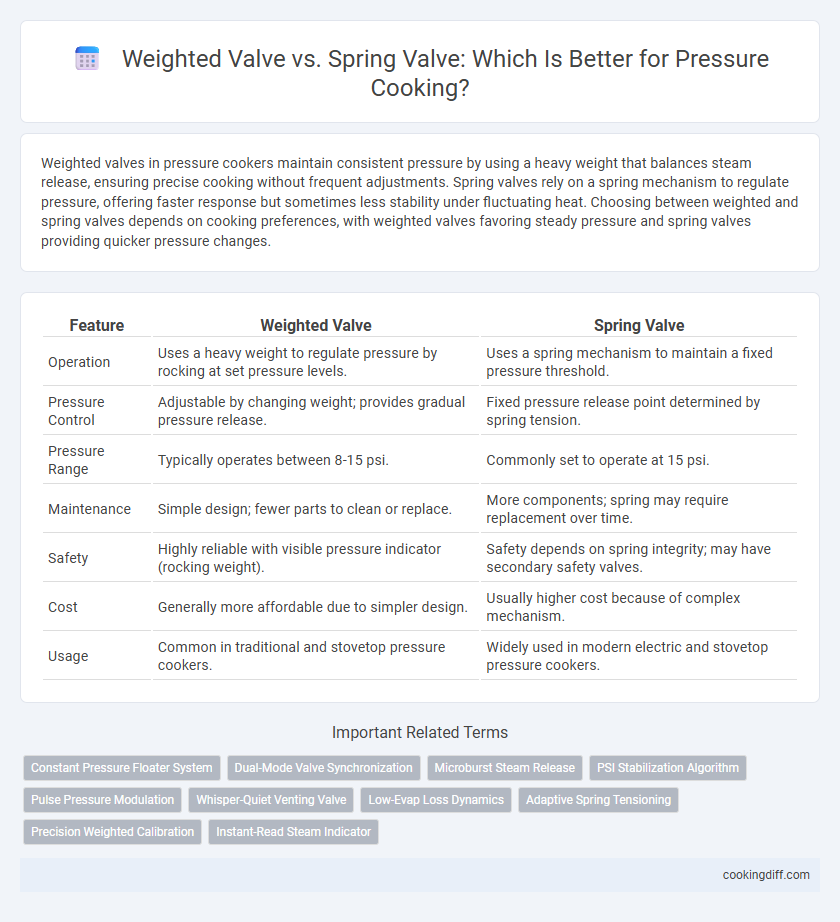

| Feature | Weighted Valve | Spring Valve |

|---|---|---|

| Operation | Uses a heavy weight to regulate pressure by rocking at set pressure levels. | Uses a spring mechanism to maintain a fixed pressure threshold. |

| Pressure Control | Adjustable by changing weight; provides gradual pressure release. | Fixed pressure release point determined by spring tension. |

| Pressure Range | Typically operates between 8-15 psi. | Commonly set to operate at 15 psi. |

| Maintenance | Simple design; fewer parts to clean or replace. | More components; spring may require replacement over time. |

| Safety | Highly reliable with visible pressure indicator (rocking weight). | Safety depends on spring integrity; may have secondary safety valves. |

| Cost | Generally more affordable due to simpler design. | Usually higher cost because of complex mechanism. |

| Usage | Common in traditional and stovetop pressure cookers. | Widely used in modern electric and stovetop pressure cookers. |

Introduction to Pressure-Cooker Valves

Pressure-cooker valves are essential components that regulate internal pressure to ensure safe and efficient cooking. Weighted and spring valves are the two main types used, each offering unique operational features and pressure control mechanisms.

- Weighted valve - Uses a heavy weight to control steam release, maintaining consistent pressure through physical weight adjustments.

- Spring valve - Employs a spring mechanism to regulate pressure, providing precise control and automatic pressure release.

- Safety function - Both valves prevent over-pressurization by releasing excess steam, safeguarding the cooker and user.

How Weighted Valves Work in Pressure-Cooking

Weighted valves regulate pressure in pressure cookers by using a specific weight that sits on a vent pipe, allowing steam to escape only when the internal pressure reaches a set level. This weight creates a consistent pressure range, ensuring even cooking and enhanced safety by preventing excessive pressure buildup. The simple mechanism of weighted valves makes them reliable and easy to maintain in pressure-cooking applications.

How Spring Valves Function in Pressure-Cooking

Spring valves regulate pressure by compressing a spring to maintain a specific pressure level inside the cooker. When the internal pressure exceeds the spring's tension, excess steam is released to prevent over-pressurization.

Spring valves provide consistent pressure control by responding dynamically to changes in steam pressure, ensuring safe cooking conditions. Unlike weighted valves, they rely on spring tension rather than gravity to release steam. This makes spring valves suitable for electric pressure cookers, where automatic pressure regulation is essential.

Pressure Regulation: Weighted vs Spring Valve

Weighted valves regulate pressure by using a specific weight that lifts to release steam at a consistent pressure level, providing precise and stable cooking conditions. This method ensures reliable pressure control especially in traditional pressure cookers commonly used in Indian cuisine.

Spring valves rely on a calibrated spring mechanism to maintain pressure, offering quicker response to pressure changes but sometimes less consistent regulation. This type is often found in modern electric pressure cookers where safety features and pressure control automation are prioritized.

Safety Features: A Comparative Analysis

Which valve provides superior safety features for pressure cooking: weighted valve or spring valve? Weighted valves rely on gravity to maintain pressure, offering a simple and reliable safety mechanism that releases excess steam slowly. Spring valves use a calibrated spring to regulate pressure, providing precise control but requiring regular maintenance to ensure safety performance.

Ease of Use and Maintenance

| Weighted Valve | Offers simple operation by regulating pressure through the weight, requiring minimal adjustment during cooking. |

| Spring Valve | Features a compact design but may need careful calibration for accurate pressure control and occasional cleaning to prevent valve sticking. |

| Maintenance | Weighted valves require less frequent maintenance, while spring valves demand regular inspection to ensure spring tension and sealing integrity remain optimal. |

Cooking Results and Food Texture

Weighted valves provide consistent pressure release, resulting in evenly cooked meals with tender textures, while spring valves offer more precise pressure control that can yield firmer or softer food depending on settings. The choice between the two valves significantly impacts cooking results, influencing moisture retention and food texture outcomes.

- Consistency in Cooking - Weighted valves maintain a steady pressure level, ensuring uniform cooking across different food types.

- Texture Variation - Spring valves allow for adjustable pressure, enabling tailored textures from firm to delicate in dishes.

- Moisture Control - Weighted valves often preserve moisture better, which enhances tenderness and juiciness.

Durability and Longevity

Weighted valves in pressure cookers typically offer greater durability due to their simple mechanical design and fewer moving parts, reducing wear over time. These valves are often made from robust materials like brass or stainless steel, enhancing their longevity under high pressure conditions.

Spring valves rely on a spring mechanism that can weaken with frequent use, potentially compromising their sealing effectiveness and requiring more frequent replacements. Maintenance of spring valves is more critical to ensure longevity, as the spring component is susceptible to corrosion and fatigue.

Price Comparison and Market Availability

Weighted valves for pressure cookers generally come at a lower price point compared to spring valves, making them more accessible for budget-conscious consumers. Market availability of weighted valve cookers is higher in traditional and developing regions, whereas spring valve models are more prevalent in modern kitchens and urban markets.

- Cost Efficiency - Weighted valves typically cost 20-30% less than spring valves due to simpler mechanics and materials.

- Market Penetration - Weighted valve cookers dominate markets in Asia and Africa, supported by widespread local production.

- Urban Demand - Spring valve pressure cookers are favored in North America and Europe, reflecting higher consumer demand for advanced features.

Choosing between weighted and spring valves depends on balancing price sensitivity with feature preferences in various market segments.

Related Important Terms

Constant Pressure Floater System

The Constant Pressure Floater System in pressure cooking utilizes a weighted valve to maintain precise pressure levels by balancing steam release, ensuring consistent cooking performance and safety. Compared to spring valves, weighted valves offer enhanced durability and reliability under high-pressure conditions, minimizing pressure fluctuations for optimal food texture and flavor.

Dual-Mode Valve Synchronization

Weighted valves in pressure cookers offer precise pressure control through adjustable weights, while spring valves provide consistent pressure regulation via spring tension. Dual-mode valve synchronization combines the accuracy of weighted valves with the stability of spring valves to enhance safety and cooking efficiency.

Microburst Steam Release

Weighted valves in pressure cookers offer precise microburst steam release, maintaining consistent pressure by allowing small, controlled bursts of steam that optimize cooking efficiency and prevent sudden pressure drops. Spring valves, while providing quicker pressure adjustments, often release steam less gradually, which can result in less stable pressure and potentially uneven cooking.

PSI Stabilization Algorithm

Weighted valves maintain precise PSI levels by releasing steam at set weights, ensuring consistent pressure during cooking cycles, while spring valves rely on calibrated springs to stabilize pressure but can fluctuate due to mechanical wear. The PSI stabilization algorithm in weighted valves continuously monitors pressure variations, adjusting venting dynamically for optimal cooking performance and enhanced safety.

Pulse Pressure Modulation

Weighted valves provide precise pulse pressure modulation by releasing steam at specific weight thresholds, ensuring consistent cooking pressure and improved texture control. Spring valves offer faster pressure release but lack the fine-tuned modulation of weighted valves, making them less effective for delicate pressure-cooking tasks requiring steady pressure variations.

Whisper-Quiet Venting Valve

Weighted valves in pressure cookers offer reliable, adjustable pressure control but tend to produce louder hissing sounds, whereas spring valves provide quieter operation but may require more precise calibration. Whisper-quiet venting valves combine the benefits by minimizing noise during pressure release while maintaining consistent pressure levels for efficient and safe pressure-cooking.

Low-Evap Loss Dynamics

Weighted valves in pressure cookers maintain a consistent pressure by allowing gradual steam release, resulting in lower evaporative loss and better moisture retention. Spring valves tend to release pressure more abruptly, which can increase evaporative loss and reduce cooking efficiency.

Adaptive Spring Tensioning

Adaptive spring tensioning in spring valve pressure cookers offers precise control over steam release, enhancing safety and cooking accuracy compared to weighted valves that rely on fixed mass to regulate pressure. This technology adjusts spring tension dynamically, ensuring consistent pressure maintenance and minimizing the risk of over-pressurization during the cooking process.

Precision Weighted Calibration

Weighted valves in pressure cookers offer precise weighted calibration by allowing exact control of steam pressure through adjustable weights, ensuring consistent cooking results. In contrast, spring valves rely on spring tension, which may vary over time, leading to less accurate pressure regulation and potential fluctuations in cooking performance.

Weighted valve vs Spring valve for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com