Pressure cookers tenderize meat by using high-pressure steam to break down tough fibers quickly, resulting in juicy and flavorful dishes in a fraction of conventional cooking time. Thermal immersion circulators, on the other hand, employ precise temperature control to gently cook meat slowly in a water bath, ensuring even doneness and enhanced tenderness without overcooking. While pressure cookers excel in speed and convenience, immersion circulators provide superior texture and consistency, ideal for delicate cuts and gourmet preparation.

Table of Comparison

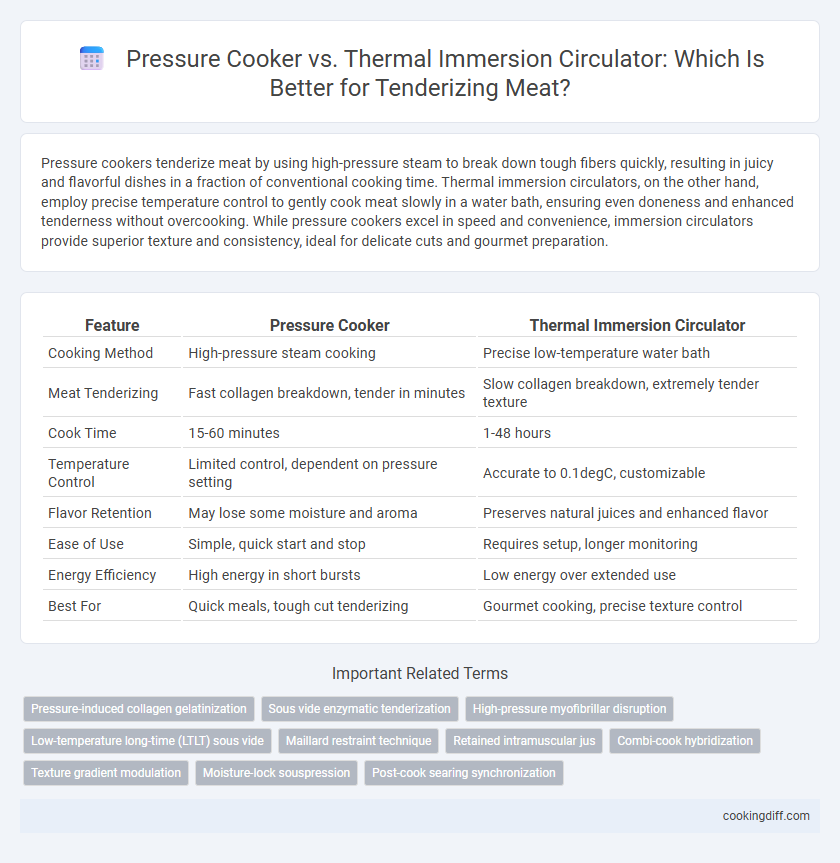

| Feature | Pressure Cooker | Thermal Immersion Circulator |

|---|---|---|

| Cooking Method | High-pressure steam cooking | Precise low-temperature water bath |

| Meat Tenderizing | Fast collagen breakdown, tender in minutes | Slow collagen breakdown, extremely tender texture |

| Cook Time | 15-60 minutes | 1-48 hours |

| Temperature Control | Limited control, dependent on pressure setting | Accurate to 0.1degC, customizable |

| Flavor Retention | May lose some moisture and aroma | Preserves natural juices and enhanced flavor |

| Ease of Use | Simple, quick start and stop | Requires setup, longer monitoring |

| Energy Efficiency | High energy in short bursts | Low energy over extended use |

| Best For | Quick meals, tough cut tenderizing | Gourmet cooking, precise texture control |

Pressure Cooker vs Thermal Immersion Circulator: Which Tenderizes Meat Better?

Pressure cookers tenderize meat rapidly by utilizing high-pressure steam that breaks down connective tissues within minutes, making them ideal for quick meal preparation. Thermal immersion circulators employ precise temperature control through sous vide cooking, allowing meat to tenderize evenly over several hours without losing moisture. While pressure cookers offer speed, thermal immersion circulators provide superior texture and flavor retention, making them the preferred choice for chefs aiming for consistent tenderness.

Key Differences in Meat Tenderization: Pressure Cooking vs Sous Vide

Pressure cooking tenderizes meat by using high pressure and temperature to break down collagen quickly, resulting in a faster cooking time. In contrast, a thermal immersion circulator (sous vide) gently cooks meat at precise low temperatures over several hours, preserving moisture and enhancing texture.

- Pressure Cooking Accelerates Collagen Breakdown - High-pressure steam rapidly softens tough fibers, significantly reducing cooking times compared to traditional methods.

- Sous Vide Maintains Juiciness and Flavor - Controlled low-temperature water baths ensure even cooking without overcooking, locking in natural juices.

- Texture Differences - Pressure-cooked meat tends to be more shredded, while sous vide yields a tender, uniform, and sliceable consistency.

Cooking Times Compared: Pressure Cooker and Thermal Immersion Circulator

Pressure cookers drastically reduce cooking times by using high pressure to raise the boiling point of water, tenderizing meat in 20 to 45 minutes depending on the cut. Thermal immersion circulators employ precise temperature control for slow, even cooking, often requiring 1 to 48 hours to achieve optimal tenderness.

Pressure cooking offers rapid results ideal for busy kitchens, while thermal immersion circulators ensure consistent texture and moisture retention through extended cooking durations. Choosing between them depends on the balance of time constraints and desired meat quality for specific recipes.

Texture and Flavor: What to Expect from Each Method

Which method delivers a more tender and flavorful meat, pressure cooking or using a thermal immersion circulator? Pressure cookers tenderize meat rapidly by breaking down collagen under high pressure and heat, resulting in a rich, concentrated flavor but a less controlled texture. Thermal immersion circulators offer precise temperature control for slow, even cooking, preserving meat's natural juices and achieving an exceptionally tender, uniform texture with enhanced flavor nuances.

Juiciness Retention: Pressure Cooker Versus Sous Vide Results

| Method | Juiciness Retention | Texture Outcome |

|---|---|---|

| Pressure Cooker | High due to sealed environment preventing moisture loss | Rapid tenderization but can risk overcooking and uneven texture |

| Thermal Immersion Circulator (Sous Vide) | Exceptional juiciness retention with precise temperature control | Consistently tender and evenly cooked meat with minimal moisture loss |

Convenience and Ease of Use: Choosing Your Meat Tenderizing Method

Pressure cookers offer rapid tenderizing with straightforward operation, making them ideal for quick meal preparation. Thermal immersion circulators require longer cooking times and precision but provide consistent results with minimal hands-on effort.

- Pressure Cooker Convenience - Quick cooking cycles reduce overall time, perfect for busy schedules.

- Immersion Circulator Precision - Maintains exact temperatures for consistent, tender texture.

- User Experience - Pressure cookers have intuitive controls, while immersion circulators may need digital familiarity.

Nutrient Preservation: Pressure Cooking vs Thermal Immersion Circulator

Pressure cooking retains nutrients by minimizing cooking time and exposure to air, effectively preserving vitamins like vitamin C and B-complex. Thermal immersion circulators maintain nutrient integrity through precise low-temperature cooking, reducing nutrient degradation compared to traditional methods. Studies show thermal immersion circulators better preserve heat-sensitive antioxidants, while pressure cookers excel in retaining water-soluble nutrients due to rapid cooking cycles.

Best Cuts of Meat for Each Tenderizing Technique

Pressure cookers excel at tenderizing tougher, collagen-rich cuts like chuck roast and short ribs by breaking down connective tissues quickly. Thermal immersion circulators are ideal for leaner, tender cuts such as filet mignon and ribeye, allowing precise temperature control to maintain juiciness and texture.

- Pressure cooker - Best for tough, fibrous cuts requiring long cooking times to become tender.

- Immersion circulator - Suited for delicate, tender cuts that benefit from slow, even cooking at controlled temperatures.

- Collagen breakdown - Pressure cookers accelerate gelatinization, transforming tough cuts into succulent dishes.

Selecting the appropriate method based on meat cut optimizes tenderness and flavor.

Cost and Equipment Considerations: Pressure Cooker or Sous Vide?

Pressure cookers offer a cost-effective solution with a one-time purchase typically ranging from $50 to $150, making them accessible for tenderizing meat quickly. In contrast, thermal immersion circulators or sous vide devices, priced between $100 and $300, provide precise temperature control but require additional equipment like vacuum sealers.

Choosing between a pressure cooker and a thermal immersion circulator depends on budget and kitchen space. Pressure cookers are compact and multifunctional, suitable for fast cooking without intricate setup. Sous vide systems deliver consistent tenderness through prolonged cooking times but involve higher initial costs and ongoing electricity use.

Related Important Terms

Pressure-induced collagen gelatinization

Pressure cookers accelerate collagen gelatinization by applying high steam pressure, which breaks down tough connective tissues in meat more rapidly than thermal immersion circulators. This pressure-induced process results in tender, flavorful meat in a fraction of the time required by slow, precise temperature control methods.

Sous vide enzymatic tenderization

A pressure cooker uses high-pressure steam to rapidly break down meat fibers, while a thermal immersion circulator enables precise temperature control for enzymatic tenderization during sous vide cooking, preserving texture and enhancing flavor. Sous vide with enzymatic tenderization activates natural proteases like papain and bromelain, resulting in more uniformly tender meat compared to the intense, fast denaturation in pressure cooking.

High-pressure myofibrillar disruption

Pressure cookers achieve superior tenderizing of meat by utilizing high-pressure myofibrillar disruption, which breaks down muscle fibers rapidly through intense steam pressure, resulting in significantly reduced cooking times. Thermal immersion circulators tenderize meat more gently via precise temperature control, but lack the high-pressure environment necessary to induce the same level of myofibrillar breakdown achieved by pressure cooking.

Low-temperature long-time (LTLT) sous vide

Low-temperature long-time (LTLT) sous vide using a thermal immersion circulator ensures precise temperature control for tenderizing meat, preserving moisture and enhancing flavor through uniform cooking. Pressure cookers tenderize meat rapidly by using high heat and steam pressure, but may sacrifice texture and subtle flavor nuances compared to the gentle, consistent heat of LTLT sous vide.

Maillard restraint technique

Pressure cookers tenderize meat rapidly by trapping steam to raise the internal temperature above boiling, which accelerates collagen breakdown but limits the Maillard reaction due to high moisture. Thermal immersion circulators gently cook meat at precise, lower temperatures that promote Maillard browning while retaining juices, enabling enhanced flavor development through controlled Maillard restraint.

Retained intramuscular jus

Pressure cookers rapidly tenderize meat by trapping steam and maintaining high pressure, which effectively retains intramuscular jus and prevents moisture loss. Thermal immersion circulators gently cook meat at precise low temperatures, preserving the juiciness but often resulting in less collagen breakdown compared to pressure cooking.

Combi-cook hybridization

Combi-cook hybridization combines pressure cooking's high-pressure steam environment with the precise temperature control of thermal immersion circulators, resulting in meat that is both tender and evenly cooked. This method leverages pressure cookers' rapid collagen breakdown while maintaining sous-vide's consistent heat, optimizing texture and flavor for superior meat tenderization.

Texture gradient modulation

Pressure cookers rapidly tenderize meat by applying high steam pressure that breaks down collagen uniformly, resulting in a consistent texture throughout. Thermal immersion circulators allow precise temperature control over extended periods, enabling gradual protein denaturation and the creation of a distinct texture gradient, offering varied tenderness from edge to center.

Moisture-lock souspression

Pressure cookers use steam pressure to rapidly break down meat fibers while locking in moisture, resulting in tender and juicy textures. Thermal immersion circulators rely on precise temperature control for slow, even cooking but may not retain moisture as effectively as the steam-sealed environment of pressure cookers.

Pressure cooker vs thermal immersion circulator for tenderizing meat. Infographic

cookingdiff.com

cookingdiff.com