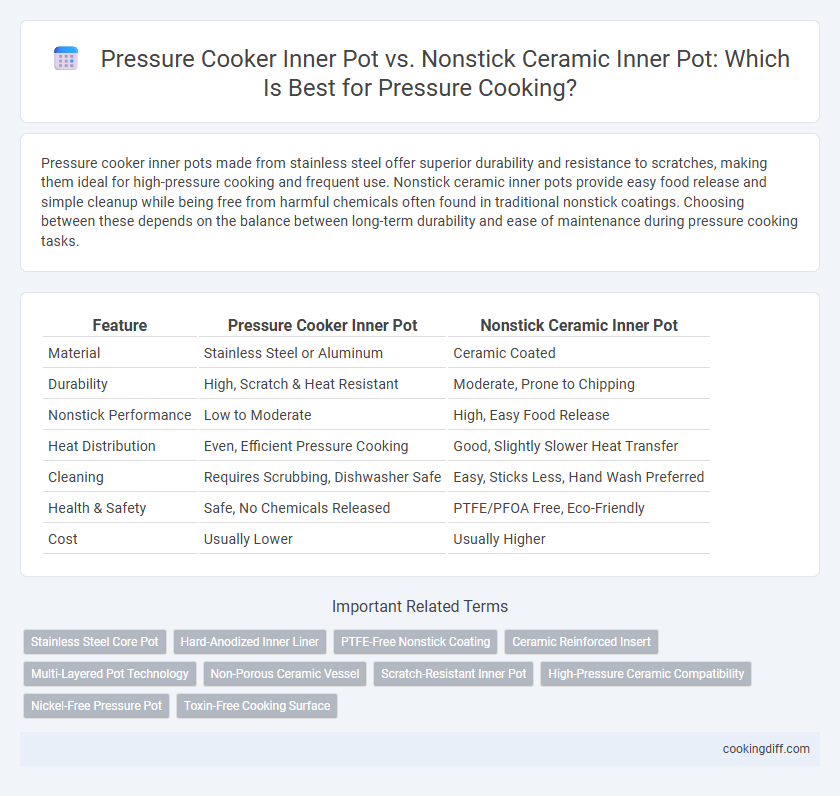

Pressure cooker inner pots made from stainless steel offer superior durability and resistance to scratches, making them ideal for high-pressure cooking and frequent use. Nonstick ceramic inner pots provide easy food release and simple cleanup while being free from harmful chemicals often found in traditional nonstick coatings. Choosing between these depends on the balance between long-term durability and ease of maintenance during pressure cooking tasks.

Table of Comparison

| Feature | Pressure Cooker Inner Pot | Nonstick Ceramic Inner Pot |

|---|---|---|

| Material | Stainless Steel or Aluminum | Ceramic Coated |

| Durability | High, Scratch & Heat Resistant | Moderate, Prone to Chipping |

| Nonstick Performance | Low to Moderate | High, Easy Food Release |

| Heat Distribution | Even, Efficient Pressure Cooking | Good, Slightly Slower Heat Transfer |

| Cleaning | Requires Scrubbing, Dishwasher Safe | Easy, Sticks Less, Hand Wash Preferred |

| Health & Safety | Safe, No Chemicals Released | PTFE/PFOA Free, Eco-Friendly |

| Cost | Usually Lower | Usually Higher |

Introduction to Pressure Cooker Inner Pots

Pressure cooker inner pots are essential for efficient heat distribution and food safety during cooking. Common materials include stainless steel and nonstick ceramic, each offering distinct advantages for pressure-cooking performance.

Stainless steel inner pots provide durability, resistance to scratching, and compatibility with high heat and metal utensils. Nonstick ceramic inner pots offer easy food release and simpler cleaning, reducing the need for excessive oil. Choosing the right inner pot depends on cooking habits, maintenance preferences, and desired longevity of the pressure cooker.

Comparing Stainless Steel and Nonstick Ceramic Inner Pots

Stainless steel inner pots offer superior durability and resistance to scratching, making them ideal for high-pressure cooking environments. Nonstick ceramic inner pots provide easy food release and cleaning but may wear down faster under intense pressure cooking conditions.

- Durability - Stainless steel pots withstand heavy use and resist corrosion, extending the lifespan of the pressure cooker.

- Nonstick Performance - Ceramic coatings prevent food from sticking, reducing the need for excessive oil and simplifying cleanup.

- Heat Distribution - Stainless steel interiors often offer more even heat distribution, enhancing cooking efficiency and consistency.

Heat Distribution: Stainless Steel vs Nonstick Ceramic

| Inner Pot Material | Heat Distribution | Impact on Pressure Cooking |

|---|---|---|

| Stainless Steel | Conducts heat evenly due to its excellent thermal conductivity and durability | Provides consistent cooking temperatures, reducing hot spots and ensuring thorough pressure cooking |

| Nonstick Ceramic | Offers moderate heat distribution but tends to have less even heating compared to stainless steel | May cause uneven cooking or require longer pressure-cooking times to achieve the same results |

Durability and Longevity of Inner Pot Materials

The inner pot of a pressure cooker made from stainless steel offers superior durability and longevity compared to nonstick ceramic pots, as it resists scratches, dents, and warping under high pressure and temperature. Nonstick ceramic inner pots may provide easier food release but tend to degrade faster with frequent use and abrasive cleaning methods. Stainless steel inner pots maintain their structural integrity and performance over years, making them a long-term investment for pressure-cooking durability.

Safety Considerations for Pressure-Cooking

Pressure cooker inner pots made of stainless steel offer superior durability and resistance to high heat, reducing the risk of warping or releasing harmful chemicals during cooking. Nonstick ceramic inner pots provide a safer alternative to traditional nonstick coatings by eliminating PTFE and PFOA, minimizing potential toxic fume emissions under pressure. Ensuring the inner pot fits securely and is free from cracks is crucial for maintaining proper pressure levels and preventing accidents while pressure-cooking.

Maintenance and Cleaning: Which Inner Pot is Easier?

The pressure cooker inner pot, typically made of stainless steel, offers durability and is dishwasher-safe, making maintenance straightforward with minimal risk of damage from scrubbing. In contrast, nonstick ceramic inner pots require gentle cleaning to preserve the ceramic coating and avoid scratches, often needing hand washing with non-abrasive sponges.

Stainless steel pots resist stains and odors better, facilitating longer-lasting cleanliness and easier maintenance under pressure-cooking conditions. Ceramic nonstick surfaces prevent food from sticking but may degrade faster if not carefully cleaned and maintained, impacting ease of use over time.

Cooking Performance Differences

How does the cooking performance of a pressure cooker inner pot compare to a nonstick ceramic inner pot during pressure-cooking? A pressure cooker inner pot, typically made of stainless steel, offers superior heat conduction and durability, ensuring even cooking and consistent pressure buildup. Nonstick ceramic inner pots provide easy food release and convenient cleaning but may heat less evenly, potentially affecting cooking times and texture.

Health Implications: Nonstick Coatings vs Stainless Steel

The stainless steel inner pot in a pressure cooker provides a non-reactive cooking surface, eliminating concerns about chemical leaching, making it a preferred choice for health-conscious users. In contrast, nonstick ceramic inner pots often contain coatings that can degrade under high heat, potentially releasing harmful substances during pressure cooking.

Nonstick ceramic coatings may wear off over time, raising questions about durability and the ingestion of coating particles. Stainless steel pots not only ensure health safety but also offer superior resistance to scratches and corrosion, promoting long-term use without compromising food quality.

Cost Comparison: Stainless Steel vs Ceramic Inner Pots

Stainless steel inner pots for pressure cookers generally come at a lower initial cost compared to nonstick ceramic pots, offering durable performance at a budget-friendly price. Ceramic inner pots tend to be pricier due to their nonstick properties and aesthetic appeal, which can increase the overall expense of pressure-cooking equipment.

- Price Range - Stainless steel pots typically range from $20 to $50, making them more affordable for most users.

- Durability Cost - Ceramic pots can incur higher replacement costs as their nonstick coating may wear out faster than stainless steel.

- Maintenance Expense - Stainless steel pots save money over time with easier cleaning and no special care required compared to ceramic coatings.

Choosing between stainless steel and ceramic inner pots affects both upfront investment and long-term maintenance costs in pressure-cooking.

Related Important Terms

Stainless Steel Core Pot

Pressure cookers with a stainless steel core inner pot offer superior heat distribution and durability compared to nonstick ceramic inner pots, which may wear out faster and are prone to chipping. The stainless steel core enhances even cooking performance and resists staining, making it ideal for high-pressure environments where consistent temperature and longevity are crucial.

Hard-Anodized Inner Liner

Hard-anodized inner liners in pressure cookers provide superior durability and enhanced heat conductivity compared to nonstick ceramic inner pots, ensuring even cooking and resistance to scratches or corrosion. The dense, impervious surface of hard-anodized aluminum optimizes pressure retention and accelerates cooking times, making it a preferred choice for heavy-duty pressure-cooking applications.

PTFE-Free Nonstick Coating

Pressure cooker inner pots with PTFE-free nonstick ceramic coatings provide a safer, toxin-free cooking surface that resists high-temperature breakdown unlike traditional nonstick pots containing PTFE, which can release harmful fumes when overheated. Ceramic inner pots offer excellent heat distribution and durability, enhancing pressure-cooking efficiency while supporting eco-friendly and health-conscious kitchen practices.

Ceramic Reinforced Insert

Ceramic reinforced inserts in pressure cooker inner pots offer superior nonstick properties and enhanced durability compared to traditional metal pots, providing even heat distribution and resistance to scratches and high temperatures. These ceramic coatings are free from PTFE and PFOA, making them a safer, eco-friendly choice for pressure cooking while ensuring easy food release and cleanup.

Multi-Layered Pot Technology

Pressure cooker inner pots with Multi-Layered Pot Technology offer superior heat distribution and durability compared to nonstick ceramic inner pots, ensuring even cooking and enhanced pressure retention. These multi-layer constructions typically combine stainless steel with aluminum cores, which optimizes thermal conductivity and prevents warping under high-pressure conditions.

Non-Porous Ceramic Vessel

Non-porous ceramic inner pots for pressure cooking offer superior resistance to staining, odors, and bacterial buildup compared to traditional pressure cooker inner pots, ensuring a healthier cooking environment. Their smooth, silica-based surface enhances heat distribution and durability while maintaining food's natural flavor without leaching harmful chemicals.

Scratch-Resistant Inner Pot

Pressure cooker inner pots made from stainless steel with a scratch-resistant coating offer superior durability and longevity compared to nonstick ceramic inner pots, which are more prone to chipping and wear over time. The scratch-resistant stainless steel surface maintains optimal heat distribution and prevents damage from metal utensils, ensuring consistent pressure-cooking performance.

High-Pressure Ceramic Compatibility

Pressure cooker inner pots made from stainless steel ensure maximum durability and high-pressure ceramic compatibility, maintaining integrity under extreme temperatures and preventing warping during extended cooking cycles. Nonstick ceramic inner pots offer excellent food release and easy cleaning but may degrade faster under consistent high-pressure, reducing their long-term performance in pressure-cooking applications.

Nickel-Free Pressure Pot

Nickel-free pressure cooker inner pots, often made from stainless steel or ceramic, provide a safer cooking environment by eliminating nickel exposure risks common in traditional metal pots. Nonstick ceramic inner pots enhance pressure-cooking with easy cleanup and even heat distribution, while ensuring a nickel-free surface that benefits users with metal sensitivities or allergies.

Pressure cooker inner pot vs Nonstick ceramic inner pot for pressure-cooking Infographic

cookingdiff.com

cookingdiff.com