Pressure cookers offer faster cooking times and user-friendly controls compared to stovetop autoclaves, making them ideal for everyday pressure-cooking needs. Stovetop autoclaves provide higher pressure capabilities and are preferred for sterilization tasks or cooking large quantities, ensuring thorough heat penetration. Choosing between a pressure cooker and stovetop autoclave depends on the balance between convenience, pressure capacity, and specific pressure-cooking requirements.

Table of Comparison

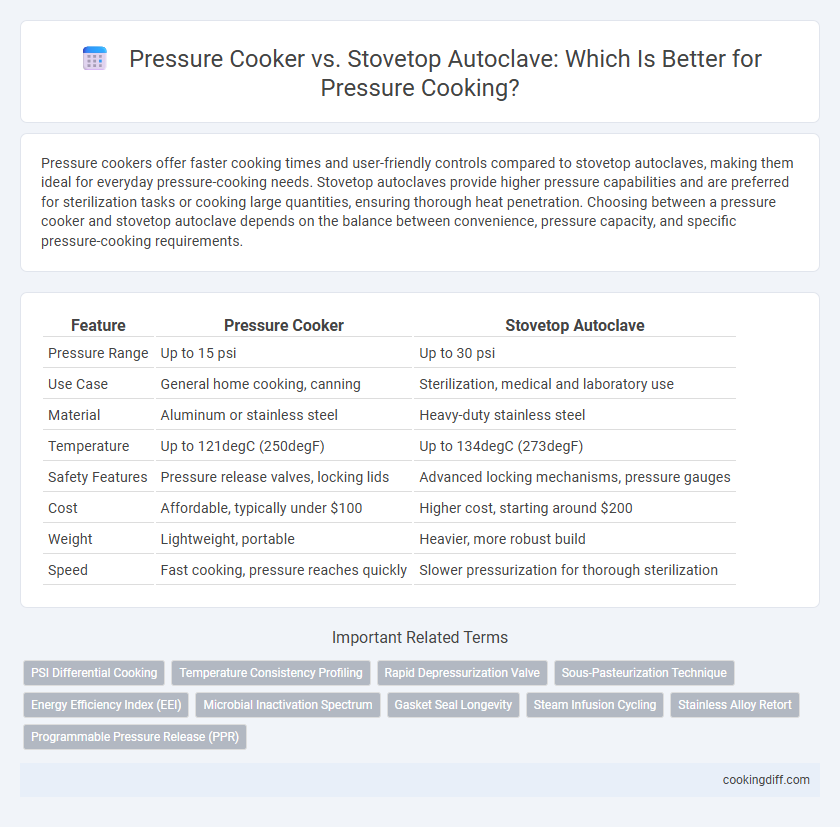

| Feature | Pressure Cooker | Stovetop Autoclave |

|---|---|---|

| Pressure Range | Up to 15 psi | Up to 30 psi |

| Use Case | General home cooking, canning | Sterilization, medical and laboratory use |

| Material | Aluminum or stainless steel | Heavy-duty stainless steel |

| Temperature | Up to 121degC (250degF) | Up to 134degC (273degF) |

| Safety Features | Pressure release valves, locking lids | Advanced locking mechanisms, pressure gauges |

| Cost | Affordable, typically under $100 | Higher cost, starting around $200 |

| Weight | Lightweight, portable | Heavier, more robust build |

| Speed | Fast cooking, pressure reaches quickly | Slower pressurization for thorough sterilization |

Introduction: Pressure Cookers vs Stovetop Autoclaves

Pressure cookers and stovetop autoclaves both use pressurized steam to cook food quickly and safely, but they serve different purposes and operate under varying conditions. Pressure cookers are designed for everyday cooking, while stovetop autoclaves are specialized for sterilization processes in laboratory or medical settings.

- Pressure Cookers - Typically used in kitchens to reduce cooking time by increasing the boiling point of water under pressure.

- Stovetop Autoclaves - Used primarily for sterilizing equipment by maintaining higher pressure and temperature over extended periods.

- Pressure and Temperature Differences - Autoclaves generally operate at higher pressures (up to 15 psi) and temperatures (121degC or higher) than standard pressure cookers.

Choosing between a pressure cooker and a stovetop autoclave depends on the intended use, whether it is for food preparation or sterilization needs.

How Pressure Cookers Work

How do pressure cookers and stovetop autoclaves differ in their pressure-cooking mechanisms? Pressure cookers increase the boiling point of water by trapping steam under high pressure, cooking food faster and preserving nutrients. Stovetop autoclaves operate similarly but reach higher pressures and temperatures, making them ideal for sterilizing canned goods safely.

Understanding Stovetop Autoclaves

Stovetop autoclaves operate by using the pressure generated from boiling water to sterilize food and equipment, often reaching pressures of up to 15 psi. They are typically constructed with heavy-duty metals to withstand high temperatures and pressure, ensuring effective pressure-cooking and sterilization.

- Durability - Stovetop autoclaves are designed with robust materials like stainless steel for long-lasting use under high pressure conditions.

- Pressure Control - They rely on a pressure gauge and weighted release valves to maintain consistent pressure levels during cooking.

- Usage - Commonly used for sterilizing medical instruments and canning food, stovetop autoclaves provide thorough heat penetration and pressure application.

Pressure Control and Accuracy

Pressure cookers use built-in pressure regulators to maintain a consistent cooking pressure, typically around 15 psi, ensuring reliable and repeatable results for most household cooking needs.

Stovetop autoclaves offer higher precision in pressure control, often with adjustable weights or gauges allowing pressure to be finely tuned beyond standard pressure cooker levels. This accuracy makes autoclaves preferable for scientific or medical sterilization where exact pressure is critical. Precise pressure monitoring prevents under or over-pressurization, enhancing safety and effectiveness.

Safety Features: A Comparative Overview

Pressure cookers feature built-in pressure release valves and locking lids that prevent accidental opening under high pressure, enhancing user safety. Stovetop autoclaves incorporate heavy-duty seals and pressure gauges, allowing precise monitoring and control of internal pressure to avoid hazardous conditions. Both appliances prioritize safety through robust mechanisms, but autoclaves typically offer more industrial-grade pressure management suited for sterilization purposes.

Cooking Speed and Efficiency

Pressure cookers significantly reduce cooking time by increasing the boiling point of water through pressurized steam, enabling faster heat transfer and efficient energy use. Stovetop autoclaves operate at higher pressure levels, making them ideal for sterilization in canning but typically require longer cooking durations compared to pressure cookers. For everyday cooking, pressure cookers offer superior speed and efficiency, while stovetop autoclaves prioritize safety and thorough sterilization over quick cooking.

Versatility in the Kitchen

| Pressure Cooker | Offers greater versatility in the kitchen with the ability to cook a wide range of dishes quickly, including stews, rice, and desserts. Suitable for everyday meal preparation and precise timing adjustments. Portable and ideal for both stovetop and electric models. |

| Stovetop Autoclave | Primarily designed for sterilization and pressure canning rather than general cooking. Limited versatility compared to standard pressure cookers, focusing on preserving foods safely under high pressure. Not commonly used for diverse culinary applications. |

Maintenance and Durability

Pressure cookers generally require less maintenance due to their simpler design and fewer parts, making them more user-friendly for everyday cooking tasks. Stovetop autoclaves, built for industrial or lab use, demand regular calibration and thorough cleaning to maintain safety and functionality.

Durability varies with material quality; pressure cookers often feature stainless steel or aluminum construction optimized for frequent household use. Stovetop autoclaves are typically made from heavy-duty stainless steel, designed to withstand higher pressures and rigorous sterilization cycles, resulting in longer lifespan under demanding conditions.

Cost Comparison: Which Is More Affordable?

Pressure cookers are generally more affordable, with prices ranging from $30 to $150 depending on brand and capacity. Stovetop autoclaves, designed for sterilization beyond cooking, usually cost between $200 and $600, making them a pricier investment.

Maintenance and operational costs for pressure cookers remain low, as they require minimal parts replacement and consume less energy. Autoclaves incur higher costs due to specialized components and greater energy consumption during prolonged cycles.

Related Important Terms

PSI Differential Cooking

Pressure cookers typically operate at 15 PSI, providing precise control for faster cooking times and nutrient retention, while stovetop autoclaves reach higher pressures of up to 30 PSI, ensuring sterilization and suitability for canning low-acid foods. The PSI differential directly impacts cooking efficiency and safety standards, with pressure cookers optimized for everyday meal preparation and autoclaves designed for industrial and preservation applications.

Temperature Consistency Profiling

Pressure cookers maintain temperature consistency through sealed environments that rapidly reach and sustain high pressures, typically around 121degC (250degF), ensuring even heat distribution during cooking. Stovetop autoclaves, designed for sterilization, provide more precise temperature control with pressure gauges and safety valves, enabling consistent temperature profiling critical for reliable preservation and microbial kill kinetics.

Rapid Depressurization Valve

The Rapid Depressurization Valve in stovetop autoclaves enables quicker and safer pressure release compared to traditional pressure cookers, minimizing cooking time and reducing the risk of accidents. This valve technology optimizes pressure control, ensuring efficient sterilization while maintaining consistent temperature and pressure levels throughout the cooking process.

Sous-Pasteurization Technique

Pressure cookers enable efficient sous-pasteurization by maintaining stable high pressure and precise temperature control, ideal for preserving nutrients and texture in delicate foods. Stovetop autoclaves, while effective for sterilization, lack the fine temperature regulation required for sous-pasteurization, making pressure cookers the preferred choice for this technique.

Energy Efficiency Index (EEI)

Pressure cookers typically achieve a higher Energy Efficiency Index (EEI) due to faster cooking times and lower energy consumption compared to stovetop autoclaves, which often require prolonged heating and higher energy input to maintain sterilization pressures. The compact design and insulation features of modern pressure cookers contribute to significant reductions in energy use, whereas stovetop autoclaves, designed primarily for sterilization rather than cooking, tend to have lower EEI values due to their extended operational durations.

Microbial Inactivation Spectrum

Pressure cookers typically achieve microbial inactivation at temperatures around 121degC by generating 15 psi of pressure, effectively killing most bacteria, viruses, and spores within a short time frame. Stovetop autoclaves, designed for sterilization, offer a broader microbial inactivation spectrum by maintaining precise temperature and pressure control, ensuring complete eradication of highly resistant microorganisms like bacterial endospores.

Gasket Seal Longevity

Pressure cookers feature durable silicone or rubber gaskets designed for frequent replacement to maintain a tight seal, whereas stovetop autoclaves often use thicker, industrial-grade gaskets built to withstand higher temperatures and prolonged use. The gasket seal longevity in stovetop autoclaves typically surpasses that of pressure cookers due to more robust materials and construction tailored for rigorous sterilization processes.

Steam Infusion Cycling

Steam infusion cycling in pressure cookers ensures rapid and consistent pressure buildup, optimizing cooking speed and flavor retention. Stovetop autoclaves, while capable of sustaining high pressures, often have slower steam infusion cycles, which can result in longer cooking times and variable heat distribution.

Stainless Alloy Retort

Stainless alloy retorts in stovetop autoclaves provide superior durability and corrosion resistance compared to standard pressure cookers, ensuring consistent high-pressure conditions ideal for sterilization and pressure-cooking. Their precision-engineered seals and thicker walls enable safer, more efficient heat retention and pressure control, making them essential for industrial-grade sterilization processes over typical kitchen pressure cookers.

Pressure Cooker vs Stovetop Autoclave for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com