Regular pressure settings in pressure cooking provide consistent and reliable cooking results suitable for most recipes, ensuring safety and efficiency. Custom pressure profiling allows for precise control over pressure levels and timing, which optimizes texture and flavor for specific ingredients or complex dishes. This tailored approach enhances cooking performance by adapting pressure conditions to meet unique culinary needs while maintaining the benefits of traditional pressure cooking.

Table of Comparison

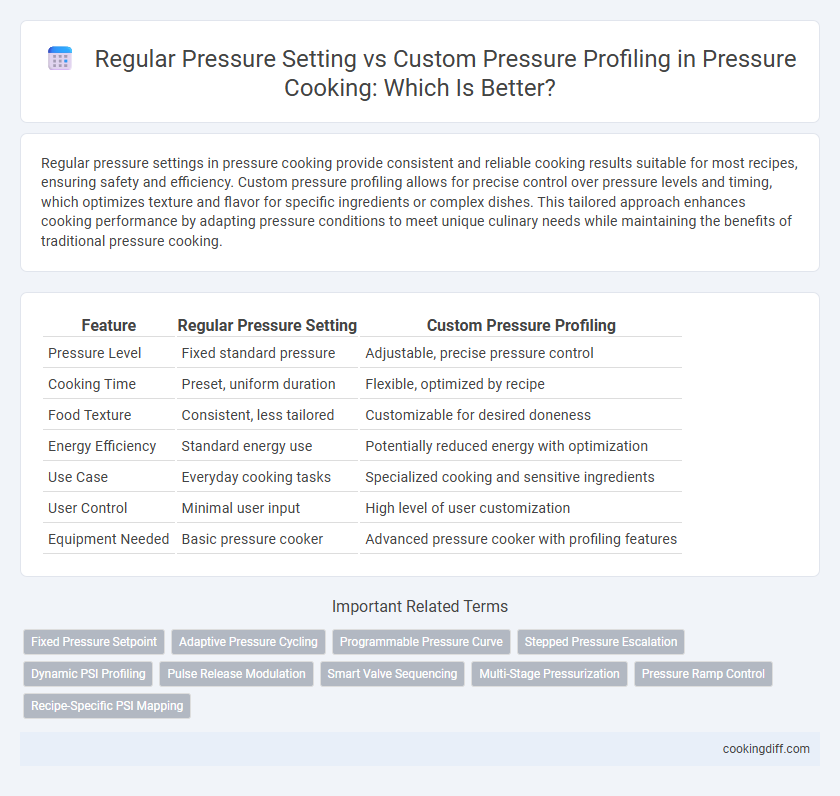

| Feature | Regular Pressure Setting | Custom Pressure Profiling |

|---|---|---|

| Pressure Level | Fixed standard pressure | Adjustable, precise pressure control |

| Cooking Time | Preset, uniform duration | Flexible, optimized by recipe |

| Food Texture | Consistent, less tailored | Customizable for desired doneness |

| Energy Efficiency | Standard energy use | Potentially reduced energy with optimization |

| Use Case | Everyday cooking tasks | Specialized cooking and sensitive ingredients |

| User Control | Minimal user input | High level of user customization |

| Equipment Needed | Basic pressure cooker | Advanced pressure cooker with profiling features |

Understanding Regular Pressure Settings in Pressure Cooking

| Regular pressure settings in pressure cooking use standardized pressure levels, typically measured in pounds per square inch (psi), such as low pressure around 6-8 psi and high pressure around 10-15 psi. These settings ensure consistent cooking times and results for common recipes by maintaining a controlled environment inside the pressure cooker. Understanding these predefined pressure levels helps avoid overcooking and ensures food safety by reaching the necessary temperature and pressure for effective cooking. |

What is Custom Pressure Profiling?

Custom pressure profiling in pressure-cooking allows precise control over pressure levels throughout the cooking cycle, adapting to specific recipe requirements and ingredient textures. This technique enhances flavor development and texture by varying pressure at different cooking stages rather than maintaining a fixed setting.

Unlike the regular pressure setting, which holds a constant pressure, custom profiling adjusts pressure dynamically, enabling improved cooking results for complex dishes. Advanced pressure cookers with programmable features support this method, offering greater culinary flexibility and efficiency.

Key Differences: Regular vs Custom Pressure Control

Regular pressure settings maintain a fixed pressure level throughout the cooking process, ensuring consistent and predictable results ideal for standard recipes like stews and beans. These settings simplify operation by automatically regulating pressure without user adjustments.

Custom pressure profiling allows precise control over pressure levels at different cooking stages, optimizing texture and flavor for complex dishes such as delicate meats or layered stews. This method requires manual input or programmable options, enabling tailored cooking curves for enhanced culinary outcomes.

Benefits of Using Regular Pressure Settings

Regular pressure settings in pressure cooking ensure consistent and reliable results by maintaining optimal pressure levels tailored for a wide range of recipes. These presets simplify the cooking process, reducing the risk of undercooking or overcooking, which enhances food texture and flavor retention. Using standard pressure settings also saves time by eliminating the need for manual adjustments, making it ideal for everyday meal preparation.

Advantages of Custom Pressure Profiling in Cooking

Custom pressure profiling in pressure-cooking allows precise control over pressure levels, optimizing cooking times and enhancing food texture compared to regular pressure settings. This method preserves delicate ingredients and flavors by adjusting pressure according to the recipe's specific needs, resulting in superior taste and nutrient retention. Chefs benefit from increased versatility and consistency, making custom profiles ideal for complex dishes and professional culinary applications.

Impact on Food Texture and Flavor

Regular pressure settings in pressure cooking provide consistent high pressure that tenderizes food efficiently but may lead to uniform texture and muted flavors. Custom pressure profiling allows precise control over pressure levels and cooking times, enhancing food texture complexity and intensifying flavor development.

- Consistent Tenderness - Regular settings ensure even softening of ingredients, ideal for tough cuts of meat.

- Enhanced Flavor Complexity - Custom profiles enable gradual pressure adjustments that deepen and layer flavors.

- Texture Control - Variable pressure settings prevent overcooking, preserving delicate textures in vegetables and seafood.

Cooking Time Comparison: Regular vs Custom Profiles

Regular pressure settings offer consistent cooking times optimized for general recipes, while custom pressure profiling allows precise adjustment of pressure levels throughout the cooking process to better suit specific ingredients. Custom profiles can reduce overall cooking time by fine-tuning pressure stages, enhancing texture and flavor development compared to the fixed times of regular settings.

- Regular pressure setting timing - Usually follows preset pressure and duration for a balance of speed and safety.

- Custom pressure profiling - Enables dynamic changes in pressure to optimize each phase of cooking for ingredient-specific needs.

- Cooking time impact - Custom profiles often shorten total cooking time by targeting precise pressure levels at key moments.

Choosing between regular and custom profiles depends on the desired control over cooking efficiency and end-food quality.

Best Dishes for Standard and Custom Pressure Settings

Which dishes benefit most from regular pressure settings versus custom pressure profiling in pressure cooking? Standard pressure settings excel with stews, beans, and tougher cuts of meat that require consistent, high heat to break down fibers. Custom pressure profiling allows precise control for delicate foods like fish, vegetables, and desserts, optimizing texture and flavor by adjusting pressure and cooking times.

Safety Considerations in Pressure Profiling

Regular pressure settings provide standardized safety limits that prevent excessive pressure buildup, reducing the risk of accidents during pressure cooking. Custom pressure profiling requires precise control and monitoring to ensure these safety parameters are not breached, maintaining safe operation throughout the cooking process.

- Constant Pressure Monitoring - Essential for custom profiling to prevent dangerous pressure fluctuations that can compromise the cooker's integrity.

- Built-in Safety Valves - Regular settings rely on factory-calibrated valves designed to release excess pressure automatically for safety assurance.

- Proper User Training - Crucial in custom profiling to correctly adjust pressure levels and avoid hazardous conditions.

Related Important Terms

Fixed Pressure Setpoint

Regular pressure setting in pressure-cooking relies on a fixed pressure setpoint, ensuring consistent cooking times and outcomes by maintaining a stable environment throughout the process. Custom pressure profiling allows for varying pressure levels at specific intervals, optimizing texture and flavor development for complex recipes.

Adaptive Pressure Cycling

Adaptive pressure cycling in pressure-cooking allows for dynamic adjustments between regular pressure settings and custom pressure profiles, optimizing cooking times and food texture. This technology enhances heat penetration and moisture retention by varying pressure levels, resulting in consistent and precisely controlled cooking outcomes.

Programmable Pressure Curve

Programmable pressure curves allow precise control over pressure cooking by customizing pressure levels and cooking durations, enhancing texture and flavor beyond regular pressure settings. This advanced technique adapts pressure changes dynamically, resulting in optimized cooking outcomes tailored to specific ingredients and recipes.

Stepped Pressure Escalation

Stepped pressure escalation in custom pressure profiling allows precise control over internal pot pressure by gradually increasing it in defined increments, optimizing texture and flavor extraction compared to a regular pressure setting's constant high pressure. This method enhances cooking precision, reduces overcooking risks, and improves the consistency of delicate ingredients in pressure-cooking.

Dynamic PSI Profiling

Dynamic PSI profiling in pressure cooking enables precise control over pressure levels throughout the cooking cycle, enhancing texture and flavor compared to regular pressure settings that maintain a static PSI. Custom pressure profiles adapt dynamically to different ingredients and recipes, optimizing cooking performance and reducing overcooking risks.

Pulse Release Modulation

Regular pressure settings in pressure-cooking maintain consistent pressure levels throughout the process, offering simplicity but less control over texture and flavor development. Custom pressure profiling with Pulse Release Modulation allows precise pressure adjustments during cooking, optimizing moisture retention and tenderness by strategically releasing steam in short bursts.

Smart Valve Sequencing

Regular pressure settings maintain constant pressure levels throughout cooking cycles, ensuring steady heat and time control but limiting flexibility for diverse recipes. Custom pressure profiling with smart valve sequencing dynamically adjusts internal pressure by modulating valve openings, optimizing texture and flavor development through precise pressure variations tailored to specific ingredients.

Multi-Stage Pressurization

Multi-stage pressurization in custom pressure profiling allows precise control over cooking stages by varying pressure levels, enhancing texture and flavor development compared to the fixed, uniform pressure setting of regular pressure cookers. This advanced technique optimizes heat and moisture distribution, leading to superior results in complex recipes like braised meats and layered stews.

Pressure Ramp Control

Regular pressure settings maintain a fixed pressure level throughout cooking, ensuring consistent heat but limiting control over texture and moisture. Custom pressure profiling with precise pressure ramp control adjusts pressure incrementally, optimizing ingredient texture, flavor infusion, and cooking efficiency by tailoring pressure curves to specific recipes.

Regular pressure setting vs Custom pressure profiling for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com