A locking handle on a pressure cooker ensures a secure seal by mechanically clamping the lid in place, providing extra safety and preventing accidental opening under high pressure. In contrast, a twist-lock lid relies on twisting the lid into a locked position, offering a simpler design but potentially less visible security. For pet owners pressure-cooking pet food, a locking handle provides more reliable safety and peace of mind during the cooking process.

Table of Comparison

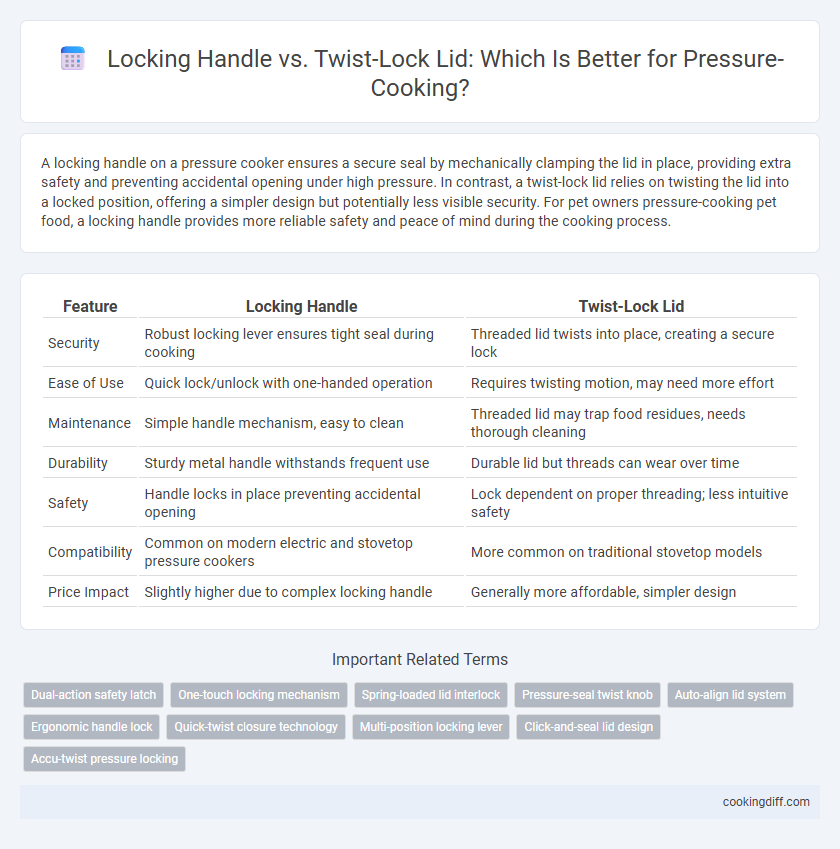

| Feature | Locking Handle | Twist-Lock Lid |

|---|---|---|

| Security | Robust locking lever ensures tight seal during cooking | Threaded lid twists into place, creating a secure lock |

| Ease of Use | Quick lock/unlock with one-handed operation | Requires twisting motion, may need more effort |

| Maintenance | Simple handle mechanism, easy to clean | Threaded lid may trap food residues, needs thorough cleaning |

| Durability | Sturdy metal handle withstands frequent use | Durable lid but threads can wear over time |

| Safety | Handle locks in place preventing accidental opening | Lock dependent on proper threading; less intuitive safety |

| Compatibility | Common on modern electric and stovetop pressure cookers | More common on traditional stovetop models |

| Price Impact | Slightly higher due to complex locking handle | Generally more affordable, simpler design |

Introduction to Pressure Cooker Lid Mechanisms

| Locking Handle | Features a lever that securely clamps the lid onto the pot, ensuring a tight seal for pressure buildup during cooking. |

| Twist-Lock Lid | Requires the lid to be twisted into place, engaging locking lugs that hold the lid firmly to maintain internal pressure safely. |

| Pressure Cooker Lid Mechanisms | Both locking handle and twist-lock lids are essential for creating an airtight seal that enables rapid pressure increase, reducing cooking time and preserving nutrients. |

Understanding Locking Handle Systems

Locking handle systems in pressure cookers ensure a secure seal by physically engaging a locking mechanism when the handle is closed, preventing the lid from being opened under pressure. This system offers a reliable and visible safety feature, as the handle remains locked until the internal pressure is fully released.

Unlike twist-lock lids that rely on twisting motion to seal, locking handles provide an added layer of mechanical safety, often with an audible or tactile click confirming secure closure. Understanding these mechanisms helps users select pressure cookers that prioritize safety and ease of use during high-pressure cooking.

Exploring Twist-Lock Lid Designs

What are the key advantages of twist-lock lid designs in pressure-cooking? Twist-lock lids provide enhanced safety by preventing accidental opening under high pressure, using interlocking mechanisms that secure the lid firmly to the pot body. Their ergonomic design also enables easier handling and faster sealing compared to traditional locking handles, improving overall cooking efficiency.

Safety Comparison: Locking Handle vs Twist-Lock

Locking handles provide a robust safety mechanism by preventing lid removal until internal pressure drops to safe levels, reducing the risk of accidental steam burns. Twist-lock lids rely on threaded engagement, which can wear over time and potentially compromise the seal, posing higher safety risks during prolonged use. Pressure cookers with locking handles often include an additional safety valve, offering a more reliable pressure release system compared to standard twist-lock designs.

Ease of Use: Which Lid Is More User-Friendly?

The locking handle on pressure cookers offers straightforward, one-handed operation, making it intuitive for beginners. Twist-lock lids require precise alignment but provide a secure seal, which some users may find less convenient initially.

- Locking Handle - Engages with a simple downward press, enhancing ease of use for quick locking and unlocking.

- Twist-lock Lid - Requires rotation to align locking tabs, demanding a bit more attention but ensuring a tight seal.

- User Familiarity - Locking handles are generally preferred by novices, while experienced cooks often favor the reliability of twist-lock lids.

Pressure Sealing Effectiveness of Each Lid Type

The locking handle pressure cooker lid provides a secure and airtight seal by mechanically engaging with the pot's rim, ensuring consistent pressure retention during cooking. Twist-lock lids rely on a threaded mechanism to seal the pot, which can sometimes lead to less uniform pressure distribution and potential steam leakage. Overall, locking handle lids tend to offer more reliable pressure sealing effectiveness, reducing the risk of cooking interruptions and safety hazards.

Maintenance and Cleaning Considerations

Locking handles on pressure cookers typically have fewer crevices, making them easier to clean and maintain. Twist-lock lids often require more detailed cleaning due to their intricate locking mechanisms and grooves where food particles can accumulate.

Maintenance of locking handles usually involves simple wiping and occasional lubrication to ensure smooth operation. Twist-lock lids demand regular disassembly to thoroughly clean the sealing ring and locking grooves, preventing buildup that can compromise the cooker's safety and performance. Proper cleaning and maintenance prolong the lifespan and efficiency of both lid types in pressure cookers.

Durability and Longevity of Locking Systems

Locking handles on pressure cookers often feature robust metal components that enhance the durability and longevity of the locking system, resisting wear from frequent high-pressure use. Twist-lock lids, while convenient, may rely more on plastic parts that can degrade faster under heat and pressure conditions.

- Metal construction of locking handle - Provides superior strength and resistance to deformation over time compared to plastic mechanisms.

- Wear resistance - Locking handles are less prone to loosening or failure after repeated pressure cycles, ensuring safer operation.

- Maintenance and replacement - Twist-lock lids typically require more frequent replacement of seals or components due to material fatigue.

Compatibility with Modern Pressure Cookers

Locking handles provide a secure and straightforward mechanism compatible with many modern pressure cookers, enhancing safety during cooking. These handles often fit a wide range of pot sizes and materials commonly used in contemporary kitchen appliances.

Twist-lock lids offer precise sealing mechanisms favored in high-end pressure cookers, ensuring airtight pressure maintenance integral to modern cooking technology. The compatibility of twist-lock lids with smart pressure cookers allows integration with digital controls and safety sensors.

Related Important Terms

Dual-action safety latch

The dual-action safety latch on pressure cookers enhances security by requiring two distinct motions to unlock, reducing the risk of accidental lid release during cooking. This feature is more commonly integrated into locking handles, providing a reliable seal and safer operation compared to twist-lock lids.

One-touch locking mechanism

One-touch locking mechanisms on pressure cookers provide a secure seal with minimal effort, enhancing safety and convenience during cooking. Unlike traditional twist-lock lids, locking handles engage instantly, reducing the risk of steam leakage and ensuring precise pressure control.

Spring-loaded lid interlock

The spring-loaded lid interlock in pressure-cooking enhances safety by automatically locking the handle when pressure builds, preventing accidental lid opening during cooking. This mechanism provides a more secure seal compared to traditional twist-lock lids, ensuring consistent pressure retention and reducing the risk of steam burns.

Pressure-seal twist knob

Pressure-seal twist knob lids offer precise control over steam release and create a secure pressure seal by twisting the lid into place, enhancing safety during pressure cooking. This mechanism minimizes the risk of accidental opening and ensures consistent internal pressure, which improves cooking efficiency compared to traditional locking handles.

Auto-align lid system

The auto-align lid system in pressure cookers ensures precise and secure locking by aligning the lid automatically with the pot, enhancing safety and ease of use compared to traditional locking handles or twist-lock lids. This mechanism reduces user error, improves pressure retention, and streamlines the cooking process for consistent results.

Ergonomic handle lock

Ergonomic handle locks in pressure cookers enhance user safety and comfort by providing secure closure with minimal effort, reducing wrist strain during cooking. Twist-lock lids often require precise alignment and firm twisting, whereas locking handles streamline the process with a more intuitive, one-step locking mechanism designed for ease of use and reliable sealing.

Quick-twist closure technology

Quick-twist closure technology in pressure cooking offers a superior advantage over traditional locking handles by enabling secure and rapid sealing of the lid, reducing preparation time significantly. This innovative mechanism ensures airtight pressure retention, enhancing cooking efficiency and safety while maintaining consistent temperature and moisture for optimal food results.

Multi-position locking lever

The multi-position locking lever in pressure cookers allows for secure and adjustable sealing, enhancing safety by accommodating variations in pressure levels and lid alignment. This feature offers greater flexibility and user control compared to traditional locking handles or twist-lock lids, ensuring a reliable seal and preventing accidental opening during cooking.

Click-and-seal lid design

The click-and-seal lid design in pressure cookers offers superior safety and ease of use compared to traditional locking handles or twist-lock lids by providing a secure, audible seal that ensures proper pressure retention. This mechanism reduces the risk of accidental opening during cooking, enhancing user confidence and maintaining optimal cooking efficiency.

Locking handle vs Twist-lock lid for pressure-cooking Infographic

cookingdiff.com

cookingdiff.com