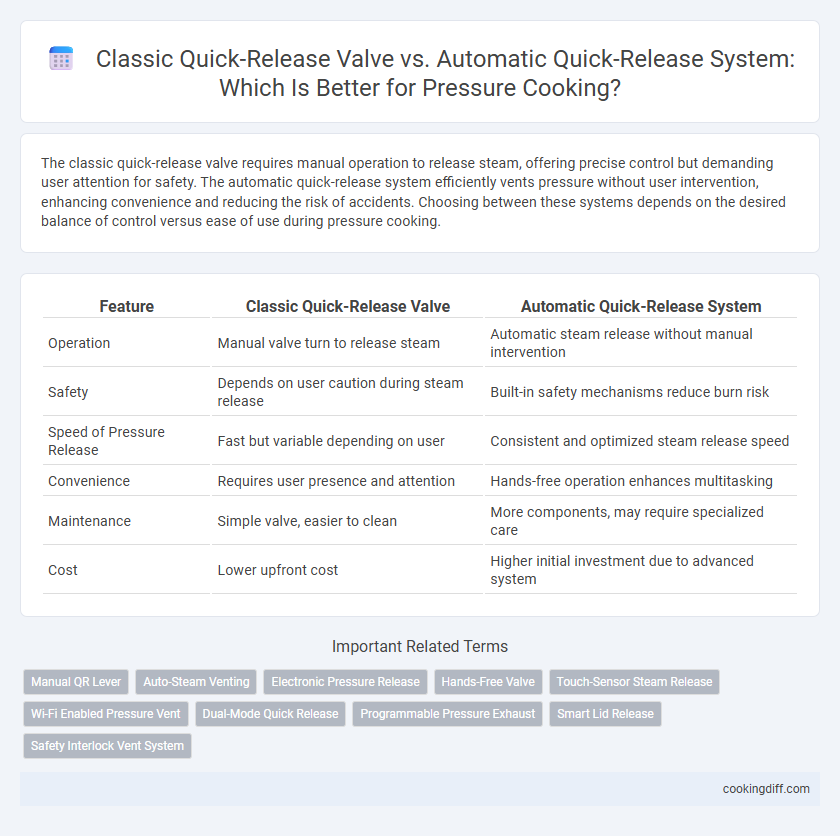

The classic quick-release valve requires manual operation to release steam, offering precise control but demanding user attention for safety. The automatic quick-release system efficiently vents pressure without user intervention, enhancing convenience and reducing the risk of accidents. Choosing between these systems depends on the desired balance of control versus ease of use during pressure cooking.

Table of Comparison

| Feature | Classic Quick-Release Valve | Automatic Quick-Release System |

|---|---|---|

| Operation | Manual valve turn to release steam | Automatic steam release without manual intervention |

| Safety | Depends on user caution during steam release | Built-in safety mechanisms reduce burn risk |

| Speed of Pressure Release | Fast but variable depending on user | Consistent and optimized steam release speed |

| Convenience | Requires user presence and attention | Hands-free operation enhances multitasking |

| Maintenance | Simple valve, easier to clean | More components, may require specialized care |

| Cost | Lower upfront cost | Higher initial investment due to advanced system |

Introduction to Quick-Release Systems in Pressure-Cooking

Classic quick-release valves require manual operation to release steam, allowing users to control pressure drop and cooking time precisely. Automatic quick-release systems use built-in sensors to release steam safely once cooking is complete, enhancing convenience and reducing risk of burns. Both systems play crucial roles in maintaining optimal cooking conditions and safety in pressure-cooking appliances.

What Is a Classic Quick-Release Valve?

A classic quick-release valve in pressure cooking is a manual mechanism that allows steam to be rapidly released by turning or lifting a valve. This method requires the user to actively control the pressure release to prevent overcooking or accidents.

- Manual Operation - The valve must be physically opened by the user to release steam quickly.

- Immediate Pressure Reduction - It rapidly decreases internal pressure, shortening cooking time.

- Safety Considerations - Requires careful handling to avoid burns from escaping steam.

This valve type provides precise control but demands user attention during pressure release.

Overview of Automatic Quick-Release Systems

Automatic quick-release systems in pressure cookers are designed to rapidly and safely release steam without requiring manual intervention, enhancing user convenience and safety. These systems activate as soon as cooking ends, minimizing the risk of burns from hot steam.

Unlike classic quick-release valves that need manual operation to vent steam, automatic systems use built-in sensors or spring-loaded mechanisms to detect pressure levels and release steam accordingly. This innovation reduces cooking time and improves overall efficiency in pressure cooking.

Key Differences: Classic vs Automatic Quick-Release

What are the key differences between a classic quick-release valve and an automatic quick-release system in pressure cooking? The classic quick-release valve requires manual operation to safely release steam, giving the user full control over the pressure drop. Automatic quick-release systems use sensors to detect pressure levels and release steam without user intervention, enhancing convenience and safety during cooking.

Safety Features of Each Quick-Release System

Classic quick-release valves allow manual pressure release, requiring careful handling to avoid steam burns. Automatic quick-release systems enhance safety by releasing pressure without direct user contact, minimizing burn risks.

- Manual Control - Classic valves require user operation, increasing risk of accidental steam exposure.

- Hands-Free Operation - Automatic systems release pressure safely without user intervention.

- Pressure Monitoring - Both systems are designed to maintain safe pressure levels within the cooker.

Speed and Efficiency Comparison

The automatic quick-release system expels steam faster than the classic quick-release valve, reducing total cooking time significantly. Efficiency improves as the automatic system minimizes manual effort and lowers the risk of steam burns.

- Speed Advantage - Automatic quick-release vents steam rapidly, cutting pressure release time by up to 50% compared to manual valves.

- Operator Safety - Reduced direct contact with steam makes the automatic system safer during pressure release.

- Energy Efficiency - Faster pressure release helps maintain optimal cooking conditions and conserves energy used for reheating.

User Convenience and Ease of Use

| Classic Quick-Release Valve | Allows manual control of steam release, offering precise timing but requiring careful handling to avoid burns. Users must stay attentive during the pressure release process, which can be less convenient for beginners or multitasking cooks. This system demands more user interaction, potentially complicating the cooking experience. |

| Automatic Quick-Release System | Features hands-free operation with built-in mechanisms that release pressure safely and efficiently without user intervention. Enhances ease of use by reducing the risk of accidents and freeing users to focus on other tasks in the kitchen. This system is ideal for improving user convenience and making pressure cooking accessible to novices. |

Maintenance and Durability Considerations

The classic quick-release valve requires regular cleaning to prevent clogging and maintain proper function, as residue buildup can affect its durability. In contrast, the automatic quick-release system often features self-cleaning components, reducing maintenance demands and prolonging the lifespan of the pressure cooker.

Maintenance of the classic valve typically involves manual inspection and occasional replacements of gaskets or valves, especially in high-use scenarios. The automatic quick-release system integrates advanced materials resistant to wear and tear, enhancing its longevity while minimizing the need for frequent servicing. Selecting a system with robust construction directly impacts overall durability and ensures safer pressure release over time.

Impact on Food Texture and Cooking Results

The classic quick-release valve allows rapid steam release, which can cause sudden temperature drops affecting delicate food texture by making it mushy or unevenly cooked. This method is ideal for foods that require precise cooking times to maintain firmness and prevent overcooking.

In contrast, the automatic quick-release system controls steam release more gradually, preserving food integrity by reducing shock to the cooking environment. This results in more consistent textures and improved cooking results, especially for meats and vegetables that benefit from slower pressure depressurization.

Related Important Terms

Manual QR Lever

The manual quick-release lever in pressure-cooking allows precise control over steam release by enabling users to manually lift or adjust the valve, preventing sudden pressure drops that can affect food texture. This method offers safer handling compared to automatic quick-release systems, which rely on built-in sensors and mechanisms for rapid pressure venting but may lack fine control during delicate cooking processes.

Auto-Steam Venting

Automatic quick-release systems with Auto-Steam Venting effectively regulate internal pressure by gradually releasing steam, reducing the risk of sudden pressure drops and enhancing cooking safety. Classic quick-release valves require manual intervention to vent steam, increasing the potential for operator error and uneven pressure reduction during pressure-cooking.

Electronic Pressure Release

Electronic pressure release systems in pressure cookers provide precise control over steam venting, enhancing safety by automatically regulating pressure levels without manual intervention. Unlike classic quick-release valves, these electronic mechanisms reduce the risk of burns and ensure consistent cooking results through programmed depressurization cycles.

Hands-Free Valve

The Classic quick-release valve requires manual intervention to safely release steam, increasing user involvement and potential risk during pressure-cooking. The Automatic quick-release system features a hands-free valve that automatically regulates pressure release, enhancing safety and convenience by minimizing direct contact with hot steam.

Touch-Sensor Steam Release

The touch-sensor steam release technology in automatic quick-release systems enhances safety and convenience by allowing precise control over pressure expulsion without manual intervention. Unlike classic quick-release valves that require manual turning, the touch-sensitive mechanism reduces the risk of burns and steam accidents, streamlining the pressure-cooking process.

Wi-Fi Enabled Pressure Vent

Wi-Fi enabled pressure cooking systems integrate an automatic quick-release valve that ensures precise steam venting based on real-time data, enhancing safety and cooking accuracy compared to the classic manual quick-release valve. These smart valves automatically regulate pressure release through connected devices, minimizing user intervention and preventing overcooking or accidents.

Dual-Mode Quick Release

The Dual-Mode Quick Release combines the Classic quick-release valve's manual control with the Automatic quick-release system's hands-free convenience, providing precise steam venting to optimize cooking times and safety. This hybrid mechanism enhances user experience by allowing immediate pressure release or gradual depressurization depending on the recipe requirements.

Programmable Pressure Exhaust

Classic quick-release valves require manual intervention to release steam, often interrupting the cooking process and risking sudden pressure drops, whereas automatic quick-release systems feature programmable pressure exhaust that precisely controls steam release, enhancing safety and consistency. Programmable pressure exhaust enables gradual depressurization based on pre-set parameters, optimizing cooking times and preserving the texture and nutrient content of pressure-cooked foods.

Smart Lid Release

The Smart Lid Release system in pressure-cooking enhances safety by automatically venting steam in a controlled manner, reducing the risk of sudden pressure drops compared to the Classic quick-release valve that requires manual operation. This intelligent mechanism ensures consistent pressure regulation and a more user-friendly experience, preventing accidents and preserving food quality.

Classic quick-release valve vs Automatic quick-release system for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com