Pressure canning uses high pressure and temperature to safely preserve low-acid foods, eliminating bacteria and spores that steam canning cannot reach. Steam canning, relying on temperature generated by steam alone, is suitable only for high-acid foods and does not achieve the necessary heat levels for safe low-acid food preservation. Choosing pressure canning for pressure-cooking ensures food safety by effectively preventing botulism and spoilage compared to steam canning methods.

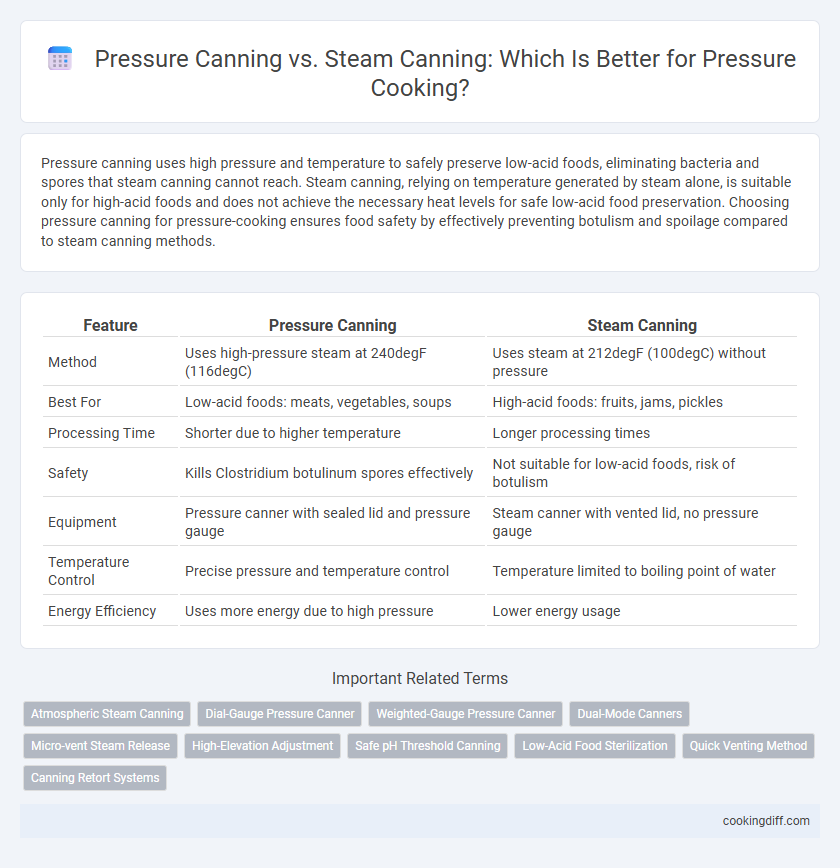

Table of Comparison

| Feature | Pressure Canning | Steam Canning |

|---|---|---|

| Method | Uses high-pressure steam at 240degF (116degC) | Uses steam at 212degF (100degC) without pressure |

| Best For | Low-acid foods: meats, vegetables, soups | High-acid foods: fruits, jams, pickles |

| Processing Time | Shorter due to higher temperature | Longer processing times |

| Safety | Kills Clostridium botulinum spores effectively | Not suitable for low-acid foods, risk of botulism |

| Equipment | Pressure canner with sealed lid and pressure gauge | Steam canner with vented lid, no pressure gauge |

| Temperature Control | Precise pressure and temperature control | Temperature limited to boiling point of water |

| Energy Efficiency | Uses more energy due to high pressure | Lower energy usage |

Introduction to Pressure Canning and Steam Canning

Pressure canning uses high temperatures and pressure to seal jars, effectively killing bacteria and preserving low-acid foods like vegetables and meats. Steam canning relies on steam heat but is suitable only for high-acid foods such as fruits, pickles, and jams.

Pressure canning operates at 240degF (116degC) or higher, ensuring the destruction of botulism spores and safe storage for low-acid foods. Steam canning reaches temperatures around 212degF (100degC), which is insufficient for low-acid food preservation, thus limiting its use to acidic products. Both methods require airtight jars and proper processing times to maintain food safety and quality during long-term storage.

How Pressure Canning Works for Home Cooks

Pressure canning uses high pressure to raise boiling temperatures above 212degF, effectively destroying harmful bacteria in low-acid foods for safe preservation. Steam canning, suitable only for high-acid foods, relies on steam heat without pressure to process jars.

- Pressure Canning Utilizes Elevated Pressure - It increases the boiling point of water to about 240degF, killing bacteria that thrive in low-acid environments.

- Sealed Environment Maintains Consistent Temperature - This ensures thorough sterilization throughout the contents during processing times.

- Essential for Low-Acid Foods - Pressure canning is necessary for meats, vegetables, and soups to prevent botulism growth safely at home.

The Basics of Steam Canning Explained

Steam canning uses a pressure cooker to create steam at 212degF (100degC) to preserve high-acid foods like fruits, pickles, and tomatoes. This method is not suitable for low-acid foods and requires precise monitoring of temperature and time for safe preservation.

Pressure canning achieves higher temperatures above 240degF (116degC) by using pressurized steam, making it ideal for low-acid foods such as vegetables, meats, and soups. The higher pressure eliminates harmful bacteria spores, ensuring safe long-term storage of low-acid canned goods.

Key Differences Between Pressure and Steam Canning

| Key Differences | Pressure Canning | Steam Canning |

|---|---|---|

| Temperature | Reaches 240degF (116degC) under pressure, necessary to kill botulism spores in low-acid foods | Uses steam at 212degF (100degC), suitable only for high-acid foods |

| Food Types | Safe for low-acid vegetables, meats, and poultry | Recommended for acidic foods like fruits, jams, and pickles |

| Processing Time | Shorter due to higher temperature | Longer to ensure safe food preservation |

| Equipment | Requires a pressure canner with a locking lid and pressure gauge | Uses a steam canner with a vented lid but no pressure gauge |

Safety Considerations in Pressure and Steam Canning

Pressure canning uses high temperatures exceeding 240degF achieved through pressurized steam, essential for safely processing low-acid foods and preventing botulism. Steam canning operates at lower temperatures around 212degF, suitable only for high-acid foods like fruits and pickles, and is not recommended for low-acid or pressure-canning-required products. Proper use of tested methods, accurate pressure gauges, and adherence to processing times are critical safety measures in pressure and steam canning to avoid foodborne illnesses.

Types of Foods Suitable for Each Method

Pressure canning is ideal for low-acid foods like vegetables, meats, and dairy that require higher temperatures to eliminate harmful bacteria. Steam canning suits high-acid foods such as fruits, pickles, and jams that can be safely preserved at lower temperatures.

- Pressure canning preserves low-acid foods - Foods with pH above 4.6 need pressure canning to prevent botulism and ensure safety.

- Steam canning is suitable for high-acid foods - High-acid foods inhibit bacterial growth and are safe for processing with steam canners.

- Texture and flavor considerations differ - Pressure canning maintains firmer textures in vegetables, while steam canning is gentler for delicate fruits.

Equipment Needed for Pressure vs. Steam Canning

Pressure canning requires a specialized pressure canner equipped with a locking lid, pressure gauge, and heavy-duty metal construction to safely maintain high temperatures above boiling water. Steam canning uses a steam canner, which is essentially a deep pot with a fitted lid and a perforated rack to hold jars above an inch of boiling water, but it lacks a pressure gauge and heavy sealing mechanisms.

Proper pressure canners are essential for processing low-acid foods to eliminate harmful bacteria, while steam canners are only recommended for high-acid foods due to their lower processing temperatures. Investing in certified equipment for each method ensures food safety and compliance with USDA canning guidelines.

Step-by-Step Process: Pressure Canning vs. Steam Canning

The step-by-step process for pressure canning requires placing jars in a specialized pressure canner that reaches 240degF to eliminate bacteria, ensuring safe preservation of low-acid foods. Steam canning involves using a steam canner that generates high-temperature steam but does not reach the high pressure necessary to safely process low-acid foods.

- Loading Jars - Place jars filled with food in the pressure canner's rack, ensuring they don't touch the sides.

- Processing Time - Maintain the required pressure for a specified time depending on the recipe and altitude to kill pathogens.

- Cooling - Gradually release pressure and allow jars to cool inside the canner to prevent jar breakage.

Steam canning is generally preferred for high-acid foods, as it does not reach pressures necessary for safe low-acid food preservation.

Pros and Cons of Pressure and Steam Canning

What are the pros and cons of pressure canning versus steam canning in pressure-cooking? Pressure canning effectively eliminates harmful bacteria, making it ideal for low-acid foods, but it requires specialized equipment and careful monitoring. Steam canning is faster and uses less water, suitable for high-acid foods, but it may not reach temperatures needed to safely preserve low-acid items.

Related Important Terms

Atmospheric Steam Canning

Atmospheric steam canning uses lower pressure and is suitable only for high-acid foods, whereas pressure canning achieves higher temperatures by increasing pressure, making it essential for safely preserving low-acid foods and preventing botulism. The precise control of pressure in pressure canning ensures thorough sterilization, which atmospheric steam canning cannot provide due to its limited atmospheric pressure environment.

Dial-Gauge Pressure Canner

Dial-gauge pressure canners provide precise pressure control essential for safe low-acid food preservation, unlike steam canners which operate at lower pressures suitable only for high-acid foods. The dial-gauge canner's ability to maintain consistent pressure ensures thorough heat penetration, preventing botulism and ensuring food safety during pressure canning.

Weighted-Gauge Pressure Canner

Weighted-gauge pressure canners maintain consistent pressure by using a weighted valve that releases excess steam, providing precise control essential for safe preservation of low-acid foods, unlike steam canners which rely on steam without pressure build-up. This accurate pressure regulation minimizes the risk of underprocessing, making weighted-gauge pressure canners the preferred choice for high-risk canning tasks requiring temperatures above 240degF.

Dual-Mode Canners

Dual-mode canners combine pressure canning and steam canning functionalities, offering versatility for home preservation of low-acid and high-acid foods. With adjustable pressure settings up to 15 PSI and controlled steam environments, these canners ensure safe sterilization and optimal texture retention for a wide range of canned products.

Micro-vent Steam Release

Pressure canning utilizes high-pressure steam to achieve temperatures above 240degF, ensuring the destruction of harmful bacteria and spores, while steam canning operates at boiling temperatures around 212degF, making it safe only for high-acid foods. The micro-vent steam release in pressure canners allows precise control of pressure buildup, enhancing safety and effectiveness by venting air pockets before sealed processing, a feature absent in steam canning methods.

High-Elevation Adjustment

High-elevation adjustments for pressure canning require increased pressure levels to compensate for lower atmospheric pressure, ensuring food safety by achieving the necessary temperature to destroy harmful bacteria. Steam canning, typically not recommended for high altitudes, lacks the precise control of pressure and temperature needed for safe preservation, making pressure canning the preferred method in elevated regions.

Safe pH Threshold Canning

Pressure canning ensures a safe pH threshold by reaching temperatures above 240degF (116degC), effectively destroying botulinum spores in low-acid foods, whereas steam canning only reaches 212degF (100degC), making it unsafe for low-acid preservation. For safe pressure-cooking canning, foods with a pH above 4.6 require pressure canning to prevent microbial growth and ensure shelf stability.

Low-Acid Food Sterilization

Pressure canning uses high-pressure steam reaching 240degF (116degC) to effectively sterilize low-acid foods, eliminating Clostridium botulinum spores and ensuring safe preservation. Steam canning, operating at boiling water temperatures of 212degF (100degC), is insufficient for sterilizing low-acid foods, making it unsuitable for safe long-term storage.

Quick Venting Method

The Quick Venting Method in pressure canning rapidly releases steam to expel air from jars, ensuring proper heating and safe preservation of low-acid foods. Compared to steam canning, which uses lower-pressure steam environments, pressure canning with quick venting achieves higher temperatures essential for destroying harmful bacteria such as Clostridium botulinum.

Pressure canning vs Steam canning for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com