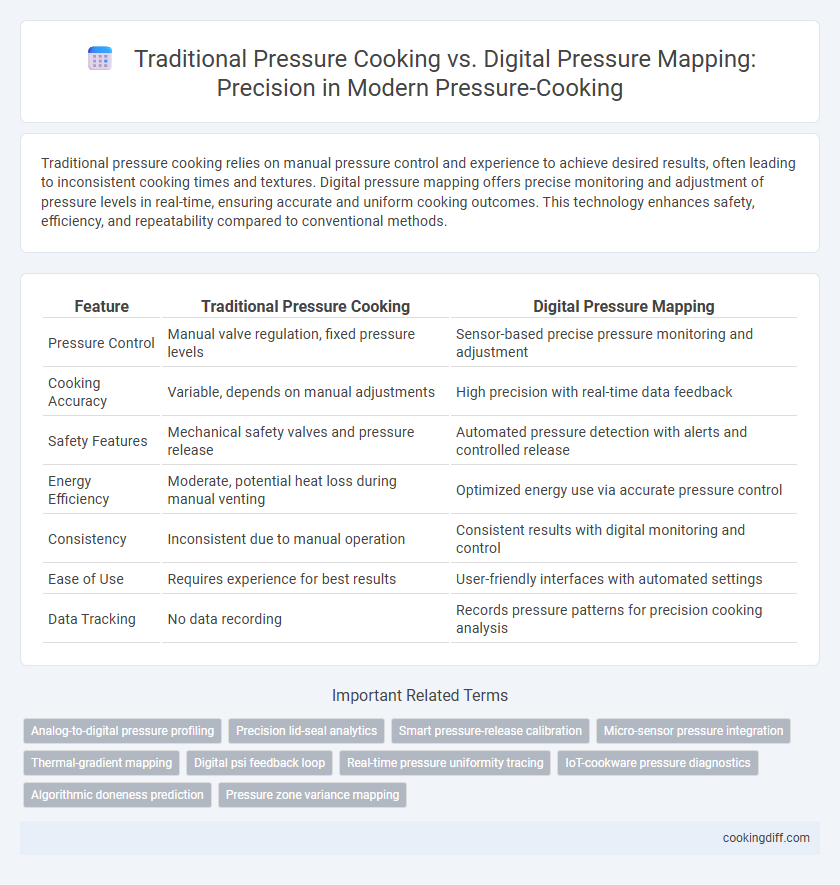

Traditional pressure cooking relies on manual pressure control and experience to achieve desired results, often leading to inconsistent cooking times and textures. Digital pressure mapping offers precise monitoring and adjustment of pressure levels in real-time, ensuring accurate and uniform cooking outcomes. This technology enhances safety, efficiency, and repeatability compared to conventional methods.

Table of Comparison

| Feature | Traditional Pressure Cooking | Digital Pressure Mapping |

|---|---|---|

| Pressure Control | Manual valve regulation, fixed pressure levels | Sensor-based precise pressure monitoring and adjustment |

| Cooking Accuracy | Variable, depends on manual adjustments | High precision with real-time data feedback |

| Safety Features | Mechanical safety valves and pressure release | Automated pressure detection with alerts and controlled release |

| Energy Efficiency | Moderate, potential heat loss during manual venting | Optimized energy use via accurate pressure control |

| Consistency | Inconsistent due to manual operation | Consistent results with digital monitoring and control |

| Ease of Use | Requires experience for best results | User-friendly interfaces with automated settings |

| Data Tracking | No data recording | Records pressure patterns for precision cooking analysis |

Introduction to Pressure Cooking Methods

Pressure cooking enhances food preparation by using steam pressure to cook ingredients faster and retain nutrients. Traditional pressure cooking relies on manual gauges, while digital pressure mapping utilizes sensors for precise control and monitoring.

- Traditional Pressure Cooking - Uses mechanical pressure regulators to maintain steam pressure and temperature during cooking.

- Digital Pressure Mapping - Employs advanced sensors and software to monitor and adjust pressure and heat with high accuracy.

- Precision Improvement - Digital systems enable consistent cooking results by providing real-time data and automated adjustments.

Overview of Traditional Pressure Cooking

Traditional pressure cooking utilizes a sealed pot and a weighted valve to maintain consistent steam pressure, enabling faster cooking times compared to conventional methods. This method relies on tactile and visual cues for pressure management without digital monitoring.

Pressure inside traditional cookers is typically regulated by the weight of the valve lifting at a preset pressure level, which provides a straightforward but less precise approach. Cooking times are estimated based on experience rather than exact data, potentially leading to variability in results. Despite this, traditional pressure cookers are valued for their durability, simplicity, and energy efficiency in many households worldwide.

What is Digital Pressure Mapping?

Digital pressure mapping utilizes advanced sensor arrays to measure pressure distribution accurately across a surface, enhancing precision compared to traditional pressure cooking methods. This technology allows for real-time monitoring and adjustments, ensuring optimal pressure and safety during the cooking process.

- Enhanced Accuracy - Digital pressure mapping provides detailed pressure data that traditional methods cannot capture.

- Real-time Monitoring - Sensors enable continuous tracking of pressure changes for precise control.

- Improved Safety - Automated pressure adjustments reduce the risk of over-pressurization and accidents.

Key Differences Between Traditional and Digital Techniques

Traditional pressure cooking relies on mechanical gauges to monitor and control pressure, offering simplicity and durability without advanced feedback systems. Digital pressure mapping incorporates sensors and microprocessors to provide precise pressure control and real-time data analysis, enhancing cooking accuracy.

While traditional methods depend on user experience for optimal results, digital techniques enable automatic adjustments based on pressure variations, reducing the risk of undercooking or overcooking. The integration of digital pressure mapping supports consistent performance and improved safety through detailed monitoring of pressure distribution.

Impact on Cooking Precision and Consistency

Traditional pressure cooking relies on manual monitoring and preset pressure levels, which can lead to variable results due to fluctuating temperature and pressure conditions. This method often requires experience to achieve consistent texture and doneness, impacting the precision of cooking outcomes.

Digital pressure mapping integrates sensors and smart controls to monitor and adjust internal pressure in real time, ensuring uniform heat distribution and exact pressure levels. This technology enhances cooking precision and consistency by reducing human error and optimizing cooking parameters for various recipes.

Time and Energy Efficiency Compared

Traditional pressure cooking relies on manual control of heat and pressure, often leading to inconsistent cooking times and higher energy consumption. Digital pressure mapping technology enables precise monitoring and adjustments, optimizing cooking duration and reducing energy waste significantly. Studies reveal that digital systems can reduce cooking time by up to 30% while improving energy efficiency by 25%, enhancing overall kitchen productivity.

Safety Features: Then and Now

Traditional pressure cooking relied on mechanical safety features such as weighted valves and rubber gaskets to maintain pressure and prevent accidents. Digital pressure mapping enhances precision by continuously monitoring pressure levels and automatically adjusting heat for safer operation.

- Mechanical Safety Valves - These valves regulate steam release to prevent excessive pressure buildup in traditional cookers.

- Rubber Gaskets - Act as seals to maintain airtight pressure but can wear out, posing safety risks over time.

- Real-Time Pressure Sensors - Digital systems provide constant feedback to control units, enabling immediate adjustments for optimal safety.

Modern digital pressure cooking significantly improves user safety by integrating advanced sensors and automated controls.

Flavor Retention and Texture Results

| Cooking Method | Flavor Retention | Texture Results |

|---|---|---|

| Traditional Pressure Cooking | Consistent heat and pressure help preserve natural flavors by minimizing evaporation and reducing cooking time compared to conventional methods. | Uniform pressure produces tender and even textures, but slight variations may occur due to less precise control over pressure levels. |

| Digital Pressure Mapping | Precise pressure sensors optimize heat distribution, enhancing flavor retention by controlling steam release and temperature fluctuations accurately. | Advanced monitoring ensures consistent and customized texture outcomes by adjusting pressure gradients in real time for different food types. |

Adaptability for Various Recipes

How does adaptability for various recipes compare between traditional pressure cooking and digital pressure mapping? Traditional pressure cooking relies on fixed settings and user intuition, limiting precise adjustments for diverse ingredients and cooking styles. Digital pressure mapping offers real-time monitoring and customizable pressure levels, enhancing adaptability for complex or delicate recipes and ensuring consistent results.

Related Important Terms

Analog-to-digital pressure profiling

Analog-to-digital pressure profiling in pressure cooking enables precise monitoring and control of internal pressure, surpassing the limitations of traditional mechanical gauges. Digital pressure mapping provides real-time data and accuracy, optimizing cooking times and ensuring consistent results with enhanced safety features.

Precision lid-seal analytics

Traditional pressure cooking relies on manual monitoring and mechanical gauges to maintain pressure, which can lead to inconsistent sealing and variable cooking results. Digital pressure mapping uses advanced sensors and real-time data analytics to ensure precise lid-seal integrity, optimizing cooking efficiency and safety by detecting minute pressure fluctuations.

Smart pressure-release calibration

Smart pressure-release calibration in digital pressure cooking allows for precise control of steam venting based on real-time pressure mapping, surpassing the estimative nature of traditional pressure-cooking methods. This innovation enhances cooking accuracy, ensuring optimal texture and flavor by adjusting pressure release rates specific to food type and cooking stage.

Micro-sensor pressure integration

Traditional pressure cooking relies on mechanical gauges and manual adjustments that often lack precise control over internal conditions, whereas digital pressure mapping with micro-sensor integration enables real-time monitoring and fine-tuned pressure regulation. This technology enhances cooking accuracy by detecting subtle pressure variations within the vessel, leading to improved texture and flavor consistency in dishes.

Thermal-gradient mapping

Traditional pressure cooking relies on manual control and consistent heat application, often resulting in uneven thermal distribution that affects cooking precision. Digital pressure mapping with thermal-gradient mapping technology enables real-time monitoring and adjustment of temperature variations, ensuring even heat distribution and optimal cooking outcomes.

Digital psi feedback loop

Digital pressure mapping with a psi feedback loop enhances traditional pressure cooking by continuously monitoring and adjusting internal pressure for precise temperature control. This real-time data integration optimizes cooking consistency, reduces overcooking risks, and improves energy efficiency compared to conventional methods.

Real-time pressure uniformity tracing

Traditional pressure cooking relies on static pressure settings that may result in uneven heat distribution, whereas digital pressure mapping enables real-time pressure uniformity tracing, ensuring precise control and consistent cooking results. This technology captures live pressure data across the cooking vessel, optimizing safety and improving recipe accuracy by detecting pressure variations instantly.

IoT-cookware pressure diagnostics

Traditional pressure cooking relies on manual gauges and timers to regulate internal pressure, often resulting in inconsistent outcomes. Digital pressure mapping integrated with IoT cookware offers real-time diagnostics and precise pressure control, enhancing cooking accuracy and safety through data-driven adjustments.

Algorithmic doneness prediction

Algorithmic doneness prediction in digital pressure cooking uses real-time data and advanced sensors to precisely control cooking pressure and time, ensuring consistent texture and flavor based on specific food types. Traditional pressure cooking relies on manual time and pressure settings without feedback mechanisms, often resulting in variable doneness and less precise cooking outcomes.

Traditional pressure cooking vs digital pressure mapping for precision. Infographic

cookingdiff.com

cookingdiff.com