Manual pressure release in pressure-cooking involves quickly venting steam to stop the cooking process immediately, preserving the texture of delicate foods. Natural release technology allows pressure to decrease gradually, enhancing flavor infusion and preventing splatter for thicker dishes like stews. Choosing between these methods depends on the recipe and desired food consistency.

Table of Comparison

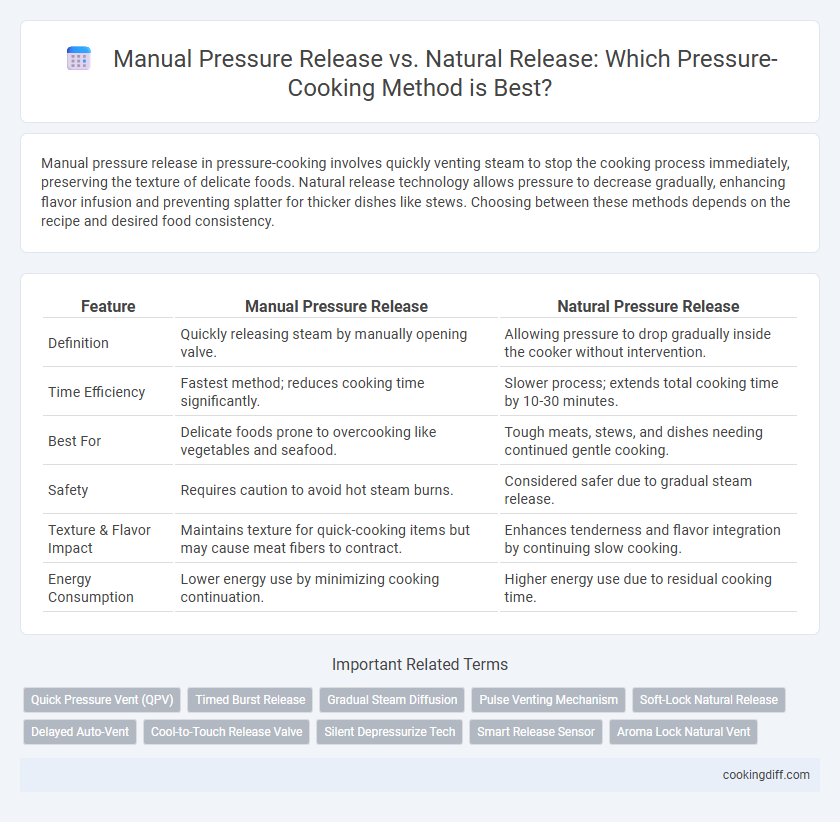

| Feature | Manual Pressure Release | Natural Pressure Release |

|---|---|---|

| Definition | Quickly releasing steam by manually opening valve. | Allowing pressure to drop gradually inside the cooker without intervention. |

| Time Efficiency | Fastest method; reduces cooking time significantly. | Slower process; extends total cooking time by 10-30 minutes. |

| Best For | Delicate foods prone to overcooking like vegetables and seafood. | Tough meats, stews, and dishes needing continued gentle cooking. |

| Safety | Requires caution to avoid hot steam burns. | Considered safer due to gradual steam release. |

| Texture & Flavor Impact | Maintains texture for quick-cooking items but may cause meat fibers to contract. | Enhances tenderness and flavor integration by continuing slow cooking. |

| Energy Consumption | Lower energy use by minimizing cooking continuation. | Higher energy use due to residual cooking time. |

Introduction to Pressure-Cooking Release Methods

Manual pressure release allows steam to be quickly vented from the cooker by manually opening the valve, providing faster access to food. Natural release technology permits pressure to reduce gradually as the cooker cools down, enhancing flavor and tenderness. Both methods are essential for controlling cooking times and ensuring optimal texture in pressure-cooked meals.

What is Manual Pressure Release?

Manual pressure release is a technique in pressure cooking where the steam valve is carefully opened to release pressure rapidly. This method allows immediate access to food, prevents overcooking, and is commonly used for delicate items. It requires caution to avoid steam burns and is ideal for recipes needing quick pressure reduction.

What is Natural Pressure Release?

| Natural Pressure Release (NPR) | Natural Pressure Release is a pressure-cooking method where the cooker is removed from heat and allowed to cool down gradually, causing the pressure to drop slowly without opening the valve. |

| Benefits | This technique preserves delicate textures and enhances flavor by avoiding sudden depressurization that can toughen food or cause splattering. |

| Usage | Ideal for foods like beans, meats, and soups that benefit from slow pressure reduction to complete the cooking process uniformly. |

Technical Differences Between Manual and Natural Release

Manual pressure release involves quickly venting steam by turning a valve, which immediately reduces pressure inside the cooker. This method is ideal for delicate foods that require quick pressure reduction to prevent overcooking.

Natural release allows pressure to drop gradually as the cooker cools down, preserving moisture and enhancing flavor retention. Technically, this method uses the slow temperature and pressure decline to complete cooking without sudden changes in internal pressure.

Safety Considerations for Each Release Method

Manual pressure release allows for rapid depressurization, which can pose safety risks such as hot steam burns if not handled carefully. It requires the user to stay attentive and use protective gear like oven mitts to avoid accidents during the release process.

Natural release lets the pressure drop gradually and reduces the risk of sudden steam bursts, making it a safer option for delicate foods and beginners. However, it takes more time and may not be suitable for recipes requiring quick pressure adjustments.

Impact on Food Texture and Flavor

Manual pressure release rapidly reduces internal pressure, which can preserve firmer textures but may cause tougher fibers in delicate foods. Natural release allows gradual pressure decrease, enhancing tenderness and flavor infusion as the food continues to cook in residual heat.

- Manual release preserves texture - Quick depressurization helps maintain the structure of firmer vegetables and cuts of meat.

- Natural release enhances tenderness - Slow pressure drop allows collagen breakdown, resulting in more tender meats and richer flavors.

- Flavor development differs - Natural release promotes deeper flavor absorption due to extended cooking time under sealed conditions.

Choosing between manual and natural pressure release impacts both texture and flavor based on the type of food and desired culinary outcome.

Time Efficiency: Manual vs Natural Release

Which method offers better time efficiency in pressure cooking: manual pressure release or natural release? Manual pressure release significantly reduces cooking time by quickly releasing steam, making it ideal for recipes needing immediate access. Natural release, while slower, allows food to finish cooking gently and retain moisture, but takes up to 20 minutes longer.

Best Recipes for Manual Release Technology

Manual pressure release technology allows for quick depressurization, perfect for recipes where overcooking can impact texture and flavor. This method is ideal for delicate ingredients that require immediate pressure release to preserve quality and taste.

- Seafood dishes - Quick release prevents overcooking and maintains the tender texture of fish and shellfish.

- Vegetables - Retains vibrant color and crispness by stopping the cooking process rapidly.

- Quick-cooking grains - Prevents mushiness and ensures perfectly cooked rice or quinoa.

Ideal Dishes for Natural Release Technology

Natural release technology is ideal for dishes like stews, roasts, and soups that benefit from gentle cooking to preserve texture and flavors. This method allows pressure to drop gradually, preventing food from becoming tough or overcooked.

Meats with connective tissues, such as brisket or pork shoulder, tenderize perfectly with natural pressure release. Delicate ingredients like beans and grains maintain their shape and consistency. Stews and soups develop richer flavors as the slow release helps meld ingredients harmoniously.

Related Important Terms

Quick Pressure Vent (QPV)

Quick Pressure Vent (QPV) technology accelerates the manual pressure release process by rapidly expelling steam, reducing cooking time while maintaining food texture and safety. Unlike natural release, which gradually decreases pressure to preserve delicate flavors and retain moisture, QPV offers efficient control for recipes requiring immediate pressure reduction.

Timed Burst Release

Timed Burst Release technology in pressure cooking combines the advantages of manual and natural release methods by automatically releasing pressure in controlled intervals, enhancing cooking precision and safety. This innovation minimizes overcooking risks and prevents sudden steam bursts, ensuring consistent texture and flavor in pressure-cooked meals.

Gradual Steam Diffusion

Manual pressure release allows steam to escape quickly by opening the valve, resulting in faster depressurization but potential food overcooking or splattering. Natural release technology enables gradual steam diffusion as the pressure declines slowly inside the cooker, preserving texture and enhancing flavor by maintaining consistent heat and moisture levels.

Pulse Venting Mechanism

Manual pressure release employs the Pulse Venting Mechanism to gradually release steam in controlled bursts, preventing sudden pressure drops and ensuring consistent cooking results. Natural release technology allows pressure to decrease slowly on its own, but lacks the precision and speed of pulse venting, which enhances safety and preserves food texture.

Soft-Lock Natural Release

Soft-Lock Natural Release technology enhances safety by gradually reducing pressure inside the cooker without sudden steam bursts, preserving food texture and flavor better than manual pressure release. This controlled depressurization method prevents accidents and ensures consistent cooking results, making it ideal for delicate ingredients and complex recipes.

Delayed Auto-Vent

Delayed Auto-Vent technology in pressure-cooking offers a controlled natural release by gradually reducing pressure, enhancing flavor retention and preventing food splatter compared to manual pressure release methods. This technology improves safety and consistency, minimizing user intervention while optimizing cooking results.

Cool-to-Touch Release Valve

Manual pressure release technology for pressure-cooking uses a cool-to-touch release valve that allows rapid steam expulsion without risk of burns, enhancing safety and control. Natural release technology relies on gradual pressure reduction, preserving food texture but taking longer and lacking the immediate safety features of cool-to-touch valves.

Silent Depressurize Tech

Silent Depressurize Tech enhances manual pressure release by allowing gradual venting of steam without loud hissing or sudden bursts, reducing noise pollution and improving kitchen safety. This technology provides controlled decompression, preserving food texture and flavors by preventing rapid pressure drops common in natural release methods.

Smart Release Sensor

The Smart Release Sensor technology optimizes pressure-cooking by automatically detecting the ideal pressure level and releasing steam safely without manual intervention, ensuring consistent cooking results. This innovation enhances convenience and safety compared to traditional manual pressure release or natural release methods, reducing the risk of burns and overcooking.

Manual pressure release vs Natural release technology for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com