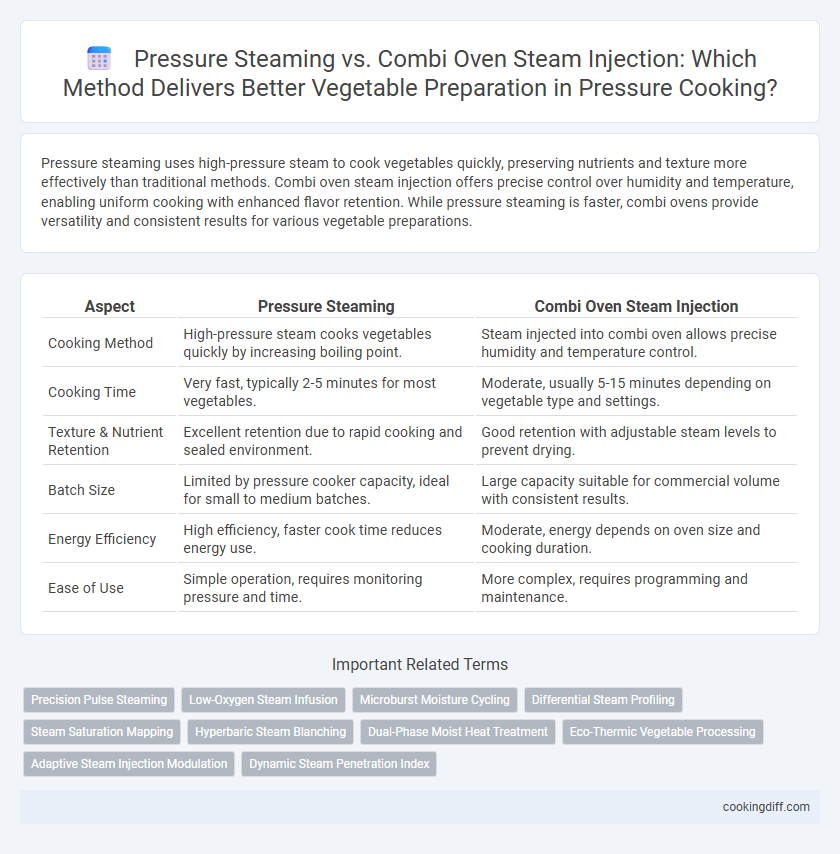

Pressure steaming uses high-pressure steam to cook vegetables quickly, preserving nutrients and texture more effectively than traditional methods. Combi oven steam injection offers precise control over humidity and temperature, enabling uniform cooking with enhanced flavor retention. While pressure steaming is faster, combi ovens provide versatility and consistent results for various vegetable preparations.

Table of Comparison

| Aspect | Pressure Steaming | Combi Oven Steam Injection |

|---|---|---|

| Cooking Method | High-pressure steam cooks vegetables quickly by increasing boiling point. | Steam injected into combi oven allows precise humidity and temperature control. |

| Cooking Time | Very fast, typically 2-5 minutes for most vegetables. | Moderate, usually 5-15 minutes depending on vegetable type and settings. |

| Texture & Nutrient Retention | Excellent retention due to rapid cooking and sealed environment. | Good retention with adjustable steam levels to prevent drying. |

| Batch Size | Limited by pressure cooker capacity, ideal for small to medium batches. | Large capacity suitable for commercial volume with consistent results. |

| Energy Efficiency | High efficiency, faster cook time reduces energy use. | Moderate, energy depends on oven size and cooking duration. |

| Ease of Use | Simple operation, requires monitoring pressure and time. | More complex, requires programming and maintenance. |

Introduction to Pressure Steaming and Combi Oven Steam Injection

Pressure steaming uses high-pressure steam to rapidly cook vegetables, preserving nutrients and texture by reducing cooking time significantly. This method enhances flavor retention and ensures even heat distribution throughout the produce.

Combi oven steam injection integrates steam into convection cooking, allowing precise control over humidity and temperature for optimal vegetable preparation. This technique enables chefs to customize cooking environments to achieve desired textures and maintain vibrant colors.

How Pressure Steaming Works for Vegetables

Pressure steaming cooks vegetables by sealing them in a high-pressure environment where steam temperature rises above 100degC, accelerating heat transfer and reducing cooking time. This method preserves nutrients and vibrant color by minimizing exposure to oxygen and leaching compared to traditional steaming. In contrast, combi oven steam injection uses controlled steam coupled with dry heat, offering versatile cooking options but generally requiring longer times to achieve the same tenderness as pressure steaming.

Combi Oven Steam Injection: Technology Overview

| Combi Oven Steam Injection Technology |

| Combi ovens utilize precise steam injection systems that rapidly introduce high-temperature steam directly into the cooking chamber, ensuring even heat distribution and optimal moisture retention in vegetables. |

| Advanced sensors and programmable controls regulate steam levels, temperature, and humidity, allowing for customizable cooking cycles that preserve nutritional value and texture more effectively than traditional pressure steaming methods. |

| The synergy of steam and convection heat in combi ovens reduces cooking time while maintaining consistent quality, making it a superior choice for large-scale vegetable preparation in commercial kitchens. |

Cooking Time Comparison: Pressure Steaming vs Combi Oven

How does cooking time compare between pressure steaming and combi oven steam injection for vegetable preparation? Pressure steaming significantly reduces cooking time by reaching higher temperatures and cooking under increased pressure, often cutting vegetable preparation time by up to 70%. Combi oven steam injection offers more controlled and even steaming but typically requires longer cooking durations, averaging 20-30 minutes depending on vegetable type.

Nutrient Retention in Vegetables: Which Method Wins?

Pressure steaming preserves nutrients in vegetables more effectively by minimizing cooking time and reducing exposure to heat and water, which limits nutrient leaching. This method retains higher levels of vitamin C, antioxidants, and water-soluble vitamins compared to traditional steaming techniques.

Combi oven steam injection offers precise temperature and humidity control, allowing for consistent cooking results but can sometimes result in greater nutrient loss due to longer cooking cycles and varying steam pressures. Studies show pressure steaming often outperforms combi oven steam injection in maintaining maximal nutrient retention in vegetables.

Flavor and Texture Outcomes for Vegetable Preparation

Pressure steaming intensifies heat and steam pressure, preserving nutrients and producing vegetables with a firmer texture and more concentrated natural flavors. Combi oven steam injection offers precise control over humidity and temperature, resulting in evenly cooked vegetables with a delicate balance of tenderness and crispness. Flavor compounds remain vibrant with combi ovens due to gentle steam infusion, while pressure steaming can enhance umami notes through rapid high-pressure cooking.

Energy Efficiency and Resource Consumption

Pressure steaming significantly reduces energy consumption by cooking vegetables faster under high pressure, while combi oven steam injection often requires longer cooking times and greater energy usage. Resource efficiency in pressure cooking is enhanced through minimal water use compared to the continuous steam generation needed in combi ovens.

- Pressure steaming reduces cooking time - Faster heat transfer under pressure lowers overall energy consumption.

- Combi ovens consume more water - Continuous steam production demands higher water and energy input.

- Pressure cooking minimizes waste - Efficient heat and moisture retention reduce resource expenditure during vegetable preparation.

Batch Size and Kitchen Workflow Considerations

Pressure steaming excels in handling large batch sizes efficiently, making it ideal for high-volume vegetable preparation. Combi oven steam injection offers greater flexibility for smaller batches and varied cooking processes, enhancing overall kitchen workflow adaptability.

- Pressure Steaming Batch Size - Designed for bulk cooking, it reduces cooking time significantly for large vegetable quantities.

- Combi Oven Flexibility - Allows precise control over steam levels, suitable for diverse batch sizes and recipes.

- Workflow Integration - Combi ovens streamline kitchen operations by combining baking, roasting, and steaming functions.

Choosing between the two depends on production scale and the need for operational versatility in the kitchen.

Equipment Costs and Maintenance Requirements

Pressure steaming equipment generally has lower initial costs compared to combi ovens with steam injection, making it more accessible for smaller kitchens. Maintenance for pressure steamers is typically straightforward, focusing on gasket replacements and pressure valve checks.

Combi ovens with steam injection require a higher upfront investment but offer versatile cooking modes beyond steaming. Maintenance involves complex components such as steam generators and electronic controls, often increasing service time and costs. This complexity demands trained technicians for regular upkeep, impacting overall operational expenses.

Related Important Terms

Precision Pulse Steaming

Precision Pulse Steaming in combi ovens offers superior control over steam injection compared to traditional pressure steaming, allowing for even moisture distribution and enhanced texture in vegetables. This technology uses timed bursts of steam to maintain consistent temperature and humidity, minimizing nutrient loss and producing perfectly cooked vegetables with vibrant color and flavor retention.

Low-Oxygen Steam Infusion

Pressure steaming leverages low-oxygen steam infusion to preserve the vibrant color, texture, and nutrients of vegetables by minimizing oxidative damage during cooking. In contrast, combi oven steam injection often introduces higher oxygen levels, potentially leading to nutrient degradation and less consistent steam penetration in vegetable preparation.

Microburst Moisture Cycling

Pressure steaming uses Microburst Moisture Cycling to rapidly infuse vegetables with steam under high pressure, preserving nutrients and texture through controlled bursts of moisture. Combi oven steam injection delivers continuous steam but lacks the precise moisture modulation of Microburst technology, often resulting in less optimal vegetable texture and nutrient retention.

Differential Steam Profiling

Pressure steaming ensures rapid, high-temperature steam penetration, preserving vegetable nutrients and texture through consistent steam pressure. Combi oven steam injection offers differential steam profiling, allowing precise control of steam levels and temperature fluctuations, optimizing cooking for varied vegetable types and desired textures.

Steam Saturation Mapping

Pressure steaming delivers uniform heat transfer through high-pressure saturated steam, resulting in consistent vegetable texture and nutrient retention, while combi oven steam injection offers variable steam saturation levels that may cause uneven cooking. Precise steam saturation mapping in pressure steamers ensures optimal humidity control, enhancing vegetable quality compared to the less consistent steam distribution found in combi ovens.

Hyperbaric Steam Blanching

Hyperbaric steam blanching in pressure steaming uses elevated pressure to enhance heat transfer, resulting in faster and more uniform vegetable cooking while preserving nutrients and color. Compared to combi oven steam injection, this method provides superior steam penetration and reduced cooking times, optimizing texture and flavor retention in vegetables.

Dual-Phase Moist Heat Treatment

Dual-phase moist heat treatment using pressure steaming rapidly softens vegetables by applying high-pressure saturated steam, preserving nutrients and vibrant colors more effectively than combi oven steam injection. Combi ovens rely on lower-pressure steam combined with dry heat, resulting in slower moisture penetration and potentially uneven texture in vegetable preparation.

Eco-Thermic Vegetable Processing

Eco-thermic vegetable processing enhances nutrient retention and texture by combining precise pressure steaming with controlled temperature cycles, unlike combi oven steam injection which often results in uneven heat distribution and higher energy consumption. Pressure steaming delivers uniform heat and rapid cooking, reducing water usage and preserving antioxidants, making it a more sustainable and efficient method for vegetable preparation.

Adaptive Steam Injection Modulation

Adaptive Steam Injection Modulation in combi ovens precisely controls steam levels to maintain optimal humidity and temperature, enhancing texture and nutrient retention in vegetables compared to pressure steaming. This technology adjusts steam flow dynamically, reducing overcooking risks while ensuring consistent, high-quality vegetable preparation.

Pressure steaming vs combi oven steam injection for vegetable preparation. Infographic

cookingdiff.com

cookingdiff.com