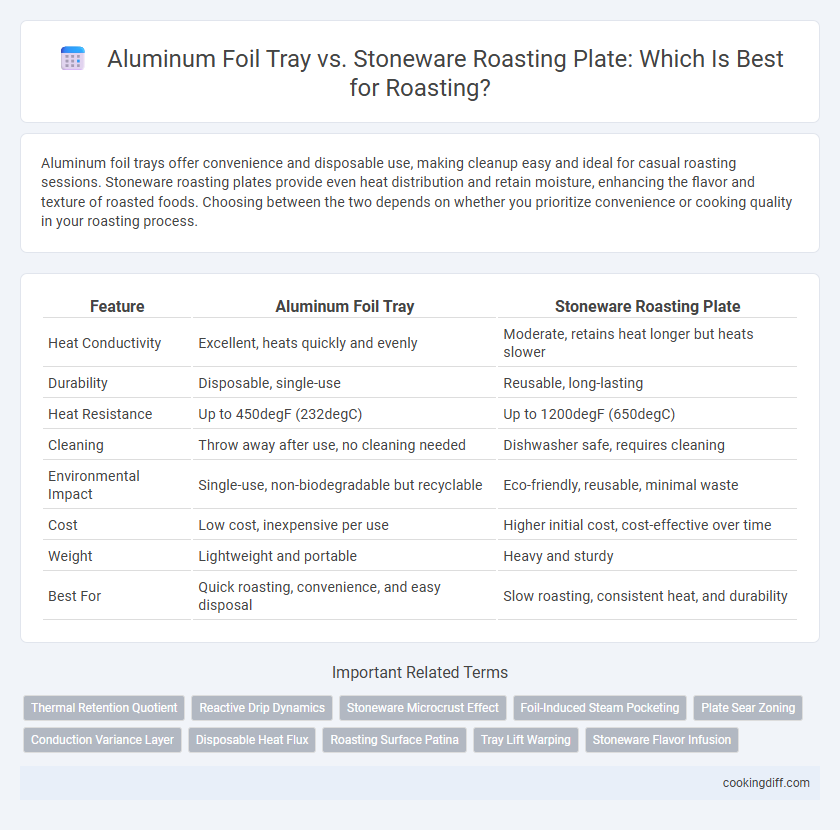

Aluminum foil trays offer convenience and disposable use, making cleanup easy and ideal for casual roasting sessions. Stoneware roasting plates provide even heat distribution and retain moisture, enhancing the flavor and texture of roasted foods. Choosing between the two depends on whether you prioritize convenience or cooking quality in your roasting process.

Table of Comparison

| Feature | Aluminum Foil Tray | Stoneware Roasting Plate |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, retains heat longer but heats slower |

| Durability | Disposable, single-use | Reusable, long-lasting |

| Heat Resistance | Up to 450degF (232degC) | Up to 1200degF (650degC) |

| Cleaning | Throw away after use, no cleaning needed | Dishwasher safe, requires cleaning |

| Environmental Impact | Single-use, non-biodegradable but recyclable | Eco-friendly, reusable, minimal waste |

| Cost | Low cost, inexpensive per use | Higher initial cost, cost-effective over time |

| Weight | Lightweight and portable | Heavy and sturdy |

| Best For | Quick roasting, convenience, and easy disposal | Slow roasting, consistent heat, and durability |

Introduction to Roasting: Aluminum Foil Tray vs Stoneware Plate

Aluminum foil trays provide excellent heat conductivity, allowing for quick and even roasting, making them ideal for high-temperature cooking and easy cleanup. Stoneware roasting plates offer superior heat retention, distributing heat slowly and uniformly, which enhances flavor development and results in tender, evenly cooked dishes. Choosing between aluminum and stoneware depends on the desired roasting time, heat distribution, and cleanup preferences.

Material Composition: Aluminum Foil vs Stoneware

Aluminum foil trays are made from thin, flexible sheets of aluminum metal, which provide excellent heat conductivity and even roasting temperatures. Stoneware roasting plates are composed of dense, porous ceramic material that retains heat longer and distributes it more evenly.

Aluminum foil trays heat up quickly, offering convenience for fast roasting and easy cleanup, but they can warp under high heat and may not retain heat as uniformly. Stoneware plates heat more slowly but maintain a consistent roasting environment, enhancing flavor and moisture retention. The ceramic composition also ensures durability and resistance to scratches, making stoneware ideal for repeated use in roasting.

Heat Distribution and Retention

Aluminum foil trays provide rapid heat conduction, ensuring food cooks quickly and evenly, but they tend to lose heat rapidly once removed from the oven. Their thin metal structure often results in less heat retention, which can affect cooking consistency for prolonged roasting.

Stoneware roasting plates excel in heat distribution by absorbing and radiating heat uniformly, creating a stable cooking environment. Their dense material retains heat longer, promoting even roasting and keeping food warmer after being taken out of the oven.

Roasting Performance: Flavor and Texture

Aluminum foil trays conduct heat quickly, resulting in faster cooking times but can sometimes cause uneven browning and a less crispy texture. Stoneware roasting plates distribute heat more evenly, enhancing flavor development and producing a tender, well-browned crust.

- Heat Conductivity - Aluminum foil trays heat rapidly but may create hot spots, while stoneware offers consistent heat distribution.

- Flavor Enhancement - Stoneware retains moisture and natural juices better, intensifying flavor compared to aluminum trays.

- Texture Quality - Stoneware promotes a crisp, golden exterior, whereas aluminum trays can yield softer, less textured results.

Safety and Health Considerations

| Material Composition | Aluminum foil trays can leach aluminum into food, especially acidic dishes, raising health concerns. Stoneware roasting plates are non-reactive and generally free from harmful chemicals, ensuring safer food preparation. |

| Heat Conductivity and Safety | Aluminum trays heat quickly but may warp or release toxins if overheated; stoneware provides even heat distribution without risk of chemical leaching, reducing safety hazards during roasting. |

| Environmental and Usage Impact | Disposable aluminum trays contribute to waste and potential exposure to metals, while stoneware is reusable, promoting eco-friendly practices and minimizing harmful health effects from repeated use. |

Cleaning and Maintenance

Which is easier to clean after roasting, an aluminum foil tray or a stoneware roasting plate? Aluminum foil trays are disposable, making cleanup quick and convenient without scrubbing. Stoneware roasting plates require soaking and gentle cleaning to maintain their durability and prevent staining over time.

Environmental Impact and Sustainability

Aluminum foil trays offer convenience but generate significant waste due to their single-use nature and energy-intensive production. Stoneware roasting plates provide a sustainable alternative by being reusable, durable, and made from natural materials with lower environmental impact.

- Aluminum Production Emissions - Extracting and refining bauxite into aluminum releases high levels of greenhouse gases contributing to climate change.

- Waste Generation - Disposable aluminum trays often end up in landfills, creating long-term environmental pollution.

- Stoneware Longevity - Stoneware plates can last for decades and reduce resource consumption and waste compared to disposable options.

Cost Comparison: Upfront and Long-Term

Aluminum foil trays offer a low upfront cost, making them an economical choice for one-time or infrequent roasting needs. Stoneware roasting plates require higher initial investment but provide durability and reusability over many cooking cycles.

Over time, the cost efficiency of stoneware plates increases as they eliminate the need for frequent replacements. Aluminum trays add recurring expenses, which can surpass the price of a quality stoneware plate if used regularly.

Versatility and Usage Scenarios

Aluminum foil trays offer exceptional convenience for single-use roasting and are ideal for easy cleanup, while stoneware roasting plates provide superior heat retention and even cooking for repeated use. The stoneware is better suited for oven-to-table presentations and slow roasting, whereas foil trays excel in portability and disposable options.

- Aluminum Foil Tray Versatility - Disposable and lightweight, perfect for outdoor events and quick meals.

- Stoneware Roasting Plate Durability - Reusable and resistant to high temperatures, enhancing cooking consistency.

- Usage Scenario Differentiation - Foil trays suit casual gatherings or transport, stoneware complements gourmet home cooking.

Choosing between the two depends on balancing convenience against cooking quality and presentation needs.

Related Important Terms

Thermal Retention Quotient

Aluminum foil trays heat up quickly but have low thermal retention quotient, causing uneven cooking and temperature drops when food is added. Stoneware roasting plates exhibit high thermal retention, distributing heat evenly and maintaining a consistent temperature throughout the roasting process, resulting in better-cooked meals.

Reactive Drip Dynamics

Aluminum foil trays offer excellent heat conductivity, promoting faster drip evaporation but may cause reactive drip pooling that affects flavor and browning. Stoneware roasting plates provide even heat distribution and absorb drippings, minimizing reactive drip buildup and enhancing caramelization with consistent roasting results.

Stoneware Microcrust Effect

Stoneware roasting plates excel in creating a microcrust on roasted foods due to their porous surface, which absorbs and evenly distributes heat, enhancing browning and texture. Unlike aluminum foil trays, stoneware's heat retention promotes consistent cooking and a desirable crispy exterior without burning or overcooking.

Foil-Induced Steam Pocketing

Aluminum foil trays often create foil-induced steam pocketing, which traps moisture and results in uneven roasting and soggy textures. Stoneware roasting plates, with their porous surface, absorb excess moisture and promote even heat distribution, preventing steam buildup for a crispier, well-roasted finish.

Plate Sear Zoning

Stoneware roasting plates provide superior plate sear zoning with even heat distribution that enhances caramelization and crust formation, while aluminum foil trays typically offer less consistent heat, leading to uneven searing. The dense material of stoneware ensures better moisture retention and flavor concentration compared to the thin, heat-conductive aluminum foil trays.

Conduction Variance Layer

Aluminum foil trays exhibit higher thermal conduction due to their metal properties, allowing for faster heat transfer and more even roasting surfaces, while stoneware roasting plates provide slower, steady heat conduction that promotes uniform cooking with retained moisture. The conduction variance layer in aluminum facilitates rapid heat distribution, contrasting with the dense composition of stoneware that diffuses heat more gradually, impacting roasting texture and consistency.

Disposable Heat Flux

Aluminum foil trays offer high disposable heat flux, enabling rapid heat transfer and even cooking, ideal for quick roasting tasks. Stoneware roasting plates retain heat longer but have lower disposable heat flux, resulting in slower heat distribution and extended roasting times.

Roasting Surface Patina

Aluminum foil trays offer a smooth, disposable roasting surface that prevents patina buildup, making cleanup easy but limiting flavor development over time. Stoneware roasting plates develop a natural patina with repeated use, enhancing heat retention and imparting richer, more complex flavors to roasted foods.

Tray Lift Warping

Aluminum foil trays are prone to tray lift warping due to uneven heat distribution and expansion, which can cause instability during roasting. Stoneware roasting plates maintain structural integrity without warping, providing consistent heat retention and a stable cooking surface for even roasting results.

Aluminum Foil Tray vs Stoneware Roasting Plate for roasting. Infographic

cookingdiff.com

cookingdiff.com