Dutch ovens provide even heat distribution and retain moisture effectively, making them ideal for slow-cooked, tender roasts with a rich, caramelized crust. Steam-injection pots release controlled steam during roasting, keeping meat juicy while speeding up the cooking process and enhancing browning. Choosing between the two depends on the desired roast texture and cooking time, with Dutch ovens favoring traditional, moist results and steam-injection pots offering faster, succulent outcomes.

Table of Comparison

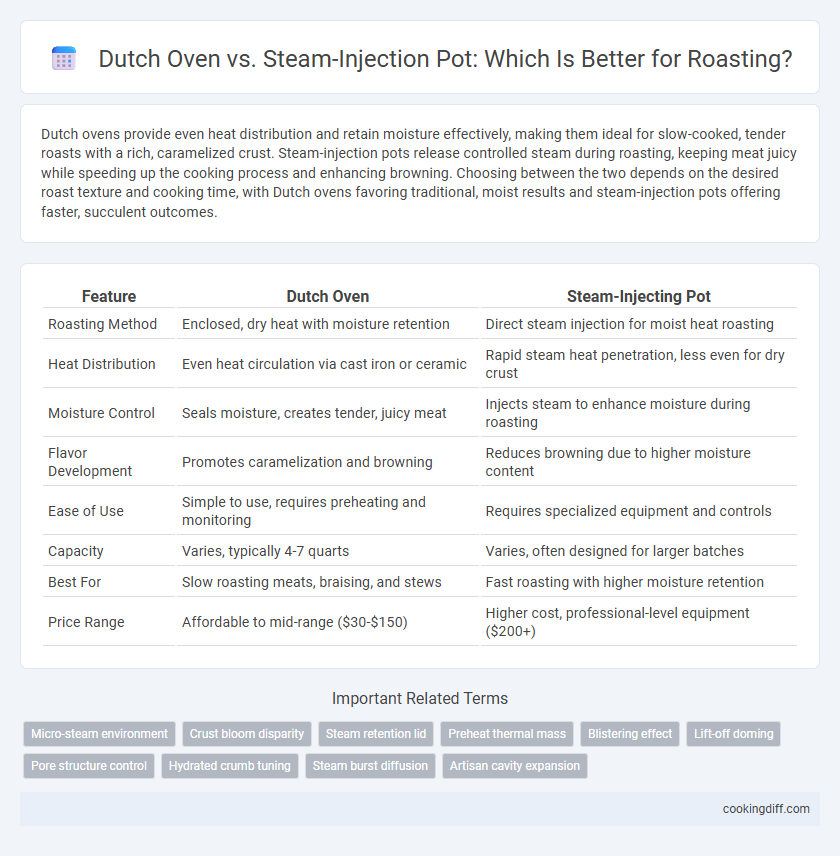

| Feature | Dutch Oven | Steam-Injecting Pot |

|---|---|---|

| Roasting Method | Enclosed, dry heat with moisture retention | Direct steam injection for moist heat roasting |

| Heat Distribution | Even heat circulation via cast iron or ceramic | Rapid steam heat penetration, less even for dry crust |

| Moisture Control | Seals moisture, creates tender, juicy meat | Injects steam to enhance moisture during roasting |

| Flavor Development | Promotes caramelization and browning | Reduces browning due to higher moisture content |

| Ease of Use | Simple to use, requires preheating and monitoring | Requires specialized equipment and controls |

| Capacity | Varies, typically 4-7 quarts | Varies, often designed for larger batches |

| Best For | Slow roasting meats, braising, and stews | Fast roasting with higher moisture retention |

| Price Range | Affordable to mid-range ($30-$150) | Higher cost, professional-level equipment ($200+) |

Introduction to Roasting: Dutch Oven vs Steam-Injection Pot

Roasting in a Dutch oven provides a traditional method that retains heat evenly and locks in moisture through its heavy cast iron construction and tight-fitting lid. Steam-injection pots offer a modern approach by injecting steam during roasting, which enhances browning and helps maintain juiciness in meats. Comparing these methods highlights the Dutch oven's slow, consistent cooking against the steam-injection pot's faster, more controlled moisture environment for optimal roast results.

Heat Retention and Distribution Comparison

Dutch ovens excel in heat retention due to their thick cast iron construction, allowing for even and consistent roasting temperatures. Their heavy lids trap moisture, enhancing heat distribution and creating a self-basting environment ideal for tender, flavorful roasts.

Steam-injection pots use controlled steam release to maintain internal humidity, improving heat conduction but requiring precise monitoring to prevent temperature fluctuations. These pots tend to have faster heat responsiveness than Dutch ovens but may lack the same level of heat retention and even distribution for extended roasting periods.

Moisture Control in Roasting Methods

How does moisture control differ between a Dutch Oven and a steam-injection pot during roasting? Dutch ovens trap steam released from the food, creating a humid environment that helps retain moisture and tenderize meat. Steam-injection pots actively introduce steam during roasting, allowing precise moisture regulation for a juicier and evenly cooked result.

Crust Development: Which Pot Performs Better?

Dutch ovens excel in crust development due to their heavy cast iron construction, which retains and evenly distributes heat, creating a consistent roasting environment. Steam-injection pots also aid crust formation by introducing moisture that enhances the Maillard reaction, producing a crisp, flavorful exterior.

While Dutch ovens provide superior heat retention for a deeply caramelized crust, steam-injection pots offer controlled humidity that prevents the crust from drying out prematurely. This balance of steam and heat promotes optimal browning and a more tender crumb. Ultimately, the choice depends on whether you prioritize a thicker, crunchier crust or a slightly softer, glossy finish.

Flavor Differences: Dutch Oven vs Steam-Injection Roasting

Dutch ovens create a deep, caramelized crust by trapping dry heat, intensifying the roasted flavor and texture. Steam-injection pots infuse moisture that enhances tenderness and amplifies natural meat juices without sacrificing browning.

- Distinct crust formation - Dutch ovens promote Maillard reaction-based browning for a richer, smoky flavor.

- Moisture retention - Steam-injection pots maintain juiciness by injecting steam to prevent drying during roasting.

- Flavor depth - Dutch ovens develop concentrated, complex taste profiles through slow heat circulation and sealed environment.

Ease of Use and Practicality in the Kitchen

Dutch ovens offer excellent heat retention and versatility, allowing for even roasting and easy temperature control. Their sturdy design and tight-fitting lids make them highly practical for slow-cooking and braising, minimizing the need for constant supervision.

Steam-injection pots enhance roasting by introducing moisture, which helps maintain juiciness and prevents drying out. These pots often require more attention to manage steam levels but can produce tender, flavorful results suited for precise cooking techniques.

Versatility for Various Recipes

Dutch ovens excel in versatility, allowing slow roasting, braising, and baking due to their heavy cast iron construction and heat retention properties. Steam-injection pots enhance roasting by maintaining moisture levels, ideal for producing tender, juicy meats and evenly cooked vegetables. Both tools suit various recipes, but Dutch ovens offer broader culinary applications beyond roasting, such as stews and bread baking.

Cleaning and Maintenance for Each Roasting Method

Cleaning a Dutch oven after roasting is straightforward due to its smooth cast iron surface that can be scrubbed without difficulty, though it requires seasoning to maintain its non-stick properties. Steam-injection pots involve more complex maintenance because the added moisture can cause mineral buildup and require regular descaling to preserve performance.

- Dutch Oven Cleaning - Typically involves hand washing and thorough drying to prevent rust and maintain seasoning.

- Steam-injection Pot Maintenance - Requires attention to steam valves and water reservoirs to avoid mineral deposits and ensure proper functionality.

- Longevity Considerations - Dutch ovens last longer with proper care, while steam-injection pots need consistent upkeep to prevent mechanical wear.

Cost and Accessibility: Dutch Oven vs Steam-Injection Pot

Dutch ovens are generally more affordable and widely accessible compared to steam-injection pots, which tend to be costlier due to advanced technology. The simplicity and availability of Dutch ovens make them a practical choice for most home cooks seeking effective roasting tools.

- Price Range - Dutch ovens typically cost between $50 and $200, whereas steam-injection pots can exceed $300.

- Availability - Dutch ovens are commonly found in department stores and online, while steam-injection pots are less widely distributed.

- Maintenance - Dutch ovens require minimal maintenance, unlike steam-injection pots which may need specialized care.

The cost-effectiveness and accessibility of Dutch ovens make them the preferred option for budget-conscious home roasting enthusiasts.

Related Important Terms

Micro-steam environment

A Dutch oven creates a micro-steam environment by trapping moisture released from the food, enhancing tenderness and promoting even cooking during roasting. In contrast, a steam-injection pot actively introduces steam to maintain high humidity levels, resulting in juicier meats and a crisp, caramelized crust.

Crust bloom disparity

Dutch ovens create a more even and well-developed crust bloom by trapping natural moisture, enhancing Maillard reactions through consistent heat retention, while steam-injection pots introduce external steam that can sometimes result in a less uniform crust due to variable humidity levels. The superior crust bloom in Dutch ovens is attributed to their airtight design, which maintains optimal moisture and temperature balance during roasting, crucial for achieving a crisp, golden exterior.

Steam retention lid

Steam-injection pots with steam retention lids maintain a moist roasting environment, enhancing meat juiciness and tenderness by trapping steam and preventing moisture loss. Dutch ovens, while effective in heat distribution, lack specialized steam retention features, resulting in less moisture preservation during roasting.

Preheat thermal mass

Dutch ovens excel in roasting due to their high thermal mass, which ensures even heat distribution and strong heat retention during preheating, creating a stable cooking environment. Steam-injection pots typically have lower thermal mass, leading to faster heat fluctuations and less consistent heat retention, which can affect roasting uniformity and browning.

Blistering effect

Dutch ovens provide a consistent, dry heat that promotes deep caramelization and a pronounced blistering effect on roasted meats. Steam-injection pots maintain moisture during cooking, which inhibits the formation of a crisp, blistered crust by reducing surface drying and browning.

Lift-off doming

Dutch ovens provide superior heat retention and even cooking for roasting, while steam-injection pots excel at creating lift-off doming by retaining moisture and generating steam within the cooking chamber. The steam-injection method enhances crust development and promotes a domed loaf with a tender crumb, making it ideal for artisanal bread roasting.

Pore structure control

Dutch ovens excel in pore structure control by providing consistent, radiant heat that promotes even caramelization and moisture retention within the roast's surface. Steam-injection pots enhance pore structure by introducing precise humidity levels, preventing excessive crust hardening and ensuring a tender, uniformly textured roast.

Hydrated crumb tuning

Dutch ovens provide superior humidity control by trapping steam released during roasting, resulting in a consistently hydrated crumb and enhanced crust development. Steam-injection pots actively introduce moisture, offering precise control over hydration levels that optimize crumb texture and create a tender, well-aerated loaf.

Steam burst diffusion

Steam-injection pots enhance roasting by creating a steam burst environment that promotes even heat diffusion, resulting in crispier skins and juicier interiors. Dutch ovens retain moisture but lack rapid steam diffusion, making them less effective for achieving the ideal Maillard reaction compared to specialized steam-injection roasting vessels.

Dutch Oven vs Steam-injection Pot for roasting. Infographic

cookingdiff.com

cookingdiff.com