Open roast pans allow for direct heat exposure, enhancing caramelization and creating a richer, more complex flavor profile in roasted pets. Steam injection trays introduce moisture during roasting, which helps retain juiciness and prevents drying out, resulting in a tender texture. Choosing between the two depends on whether you prioritize a crisp, flavorful crust or a moist, succulent interior.

Table of Comparison

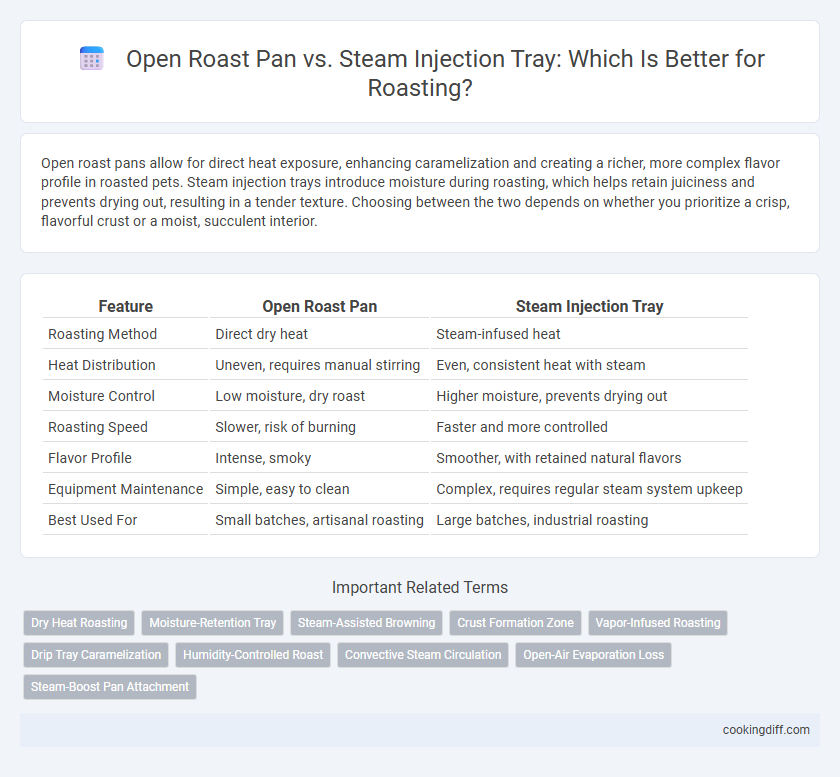

| Feature | Open Roast Pan | Steam Injection Tray |

|---|---|---|

| Roasting Method | Direct dry heat | Steam-infused heat |

| Heat Distribution | Uneven, requires manual stirring | Even, consistent heat with steam |

| Moisture Control | Low moisture, dry roast | Higher moisture, prevents drying out |

| Roasting Speed | Slower, risk of burning | Faster and more controlled |

| Flavor Profile | Intense, smoky | Smoother, with retained natural flavors |

| Equipment Maintenance | Simple, easy to clean | Complex, requires regular steam system upkeep |

| Best Used For | Small batches, artisanal roasting | Large batches, industrial roasting |

Open Roast Pan vs Steam Injection Tray: Key Differences

Open roast pans provide direct heat exposure for a more intense roasting process, while steam injection trays introduce moisture to control temperature and enhance flavor development. The choice between these methods significantly influences roast uniformity and final product texture.

- Heat Distribution - Open roast pans offer even, dry heat that crisps surfaces effectively.

- Moisture Control - Steam injection trays infuse controlled moisture to prevent drying and foster caramelization.

- Flavor Impact - Steam injection enhances caramel notes, whereas open pans produce a robust roast character.

Selecting between open roast pans and steam injection trays depends on the desired roast profile and product characteristics.

How Each Method Influences Roasting Results

How does the roasting method affect flavor development in coffee beans? Open roast pans expose beans directly to radiant heat, promoting a more uniform roast with distinct caramelization and complex flavor profiles. Steam injection trays introduce moisture and heat simultaneously, which can enhance bean expansion and retain more acidity, resulting in a brighter and cleaner cup.

Flavor Development: Dry Heat vs Moist Heat

Open roast pans utilize dry heat, enhancing Maillard reactions that intensify complex, caramelized flavors and a crispy texture in roasted products. This method promotes deep, robust flavor development by evaporating moisture swiftly during roasting.

Steam injection trays introduce moist heat, preserving the food's natural juices and creating a tender, succulent texture with subtle flavor notes. Moist heat inhibits excessive drying, allowing flavors to develop more gently and evenly throughout the roasting process.

Texture and Crust: Crispness Versus Moisture

Open roast pans promote intense dry heat circulation, resulting in a crispier texture and well-defined crust on roasted foods. Steam injection trays introduce moisture during roasting, which helps maintain tenderness but often yields a softer crust.

Roasting with an open pan enhances Maillard reaction, boosting browning and crispness, ideal for meats and vegetables requiring a crunchy crust. Steam trays infuse controlled humidity that prevents drying out, preserving juiciness and a flexible outer layer. Choosing between methods depends on whether a crunchy crust or a moist, tender bite is prioritized in the final dish.

Best Foods for Open Roast Pans

Open roast pans excel at creating crispy textures and caramelized flavors for foods that benefit from direct heat exposure. They are ideal for roasting vegetables and meats that require moisture evaporation to enhance flavor and texture.

- Root vegetables - Open roast pans promote caramelization, making carrots, potatoes, and beets tender and sweet.

- Poultry - Chickens and turkeys develop crispy skin and juicy interiors due to even dry heat circulation.

- Steaks and roasts - The direct heat intensifies browning and forms a flavorful crust on beef and pork cuts.

Ideal Dishes for Steam Injection Trays

Steam injection trays are ideal for roasting delicate foods like poultry and vegetables, where moisture retention is crucial to prevent drying out. These trays create a humid environment that helps maintain juiciness and enhances flavor development. Unlike open roast pans, steam injection trays are especially effective for dishes requiring gentle, even cooking with minimal browning.

Equipment Requirements and Ease of Use

Open roast pans require simple, low-maintenance equipment, making them accessible for small-scale roasting setups. Steam injection trays involve more complex machinery with built-in steam generators, increasing both initial investment and operational demands.

- Equipment Simplicity - Open roast pans use straightforward heating elements without the need for steam systems, reducing technical complexity.

- Operational Ease - Steam injection trays demand precise control of steam flow, adding layers of operational monitoring and skill.

- Maintenance Requirements - Open pans have fewer components prone to failure, whereas steam trays necessitate regular inspection to prevent corrosion and ensure steam quality.

Cooking Times and Temperature Control

Open roast pans typically offer longer cooking times due to uneven heat distribution, requiring more attention to temperature control to avoid overcooking. Steam injection trays provide precise temperature regulation and faster cooking by introducing moisture and heat simultaneously, enhancing heat transfer and reducing roast time. Optimal roasting results depend on the balance between cooking time and temperature control, with steam injection trays excelling in consistency and efficiency.

Nutrient Retention: Which Method Wins?

Open roast pans expose food to direct dry heat, which can cause significant nutrient loss, especially of heat-sensitive vitamins like vitamin C and some B vitamins. Steam injection trays introduce moisture during roasting, helping to preserve these nutrients by reducing oxidative damage and maintaining a more stable cooking environment.

Research indicates that steam injection trays retain higher levels of antioxidants and essential minerals compared to open roast pans. This method also minimizes dehydration, helping to preserve the food's natural texture and nutritional profile more effectively.

Related Important Terms

Dry Heat Roasting

Open roast pans provide direct exposure to high temperatures ideal for dry heat roasting, enhancing Maillard reactions and developing complex flavors through caramelization. Steam injection trays introduce moisture that can inhibit surface browning but help control internal temperature, making them less suitable for achieving the crisp texture typical of dry heat roasting.

Moisture-Retention Tray

Moisture-retention trays in steam injection roasters enhance flavor development by maintaining optimal humidity levels during the roast, preventing excessive bean drying and preserving essential oils. Open roast pans, lacking moisture control, often lead to increased bean weight loss and uneven roast profiles due to higher moisture evaporation rates.

Steam-Assisted Browning

Steam-assisted browning in roasting enhances Maillard reactions by injecting controlled steam into the roast environment, unlike open roast pans that rely solely on dry heat. The steam injection tray maintains surface moisture, ensuring even caramelization and a tender crust, which optimizes flavor development and color uniformity in roasted products.

Crust Formation Zone

The Open roast pan promotes direct heat transfer, intensifying the Crust Formation Zone for a deeply caramelized crust, while the Steam injection tray introduces moisture that delays crust setting but enhances flavor development through Maillard reactions. Optimizing heat and humidity balance in these methods is crucial for achieving the desired texture and appearance in roasted products.

Vapor-Infused Roasting

Vapor-infused roasting combines enhanced flavor extraction and moisture retention, achieved more effectively through steam injection trays that release consistent steam during roasting, compared to traditional open roast pans which allow more direct heat but less controlled vapor interaction. Steam injection trays optimize the Maillard reaction by maintaining a humid environment, resulting in richer aroma and juicier texture, while open roast pans excel in developing crispness and caramelization.

Drip Tray Caramelization

Open roast pans allow direct heat exposure, promoting intense drip tray caramelization that enhances flavor complexity through Maillard reactions. Steam injection trays reduce drip buildup by injecting moisture, resulting in a lighter caramelization level and a cleaner tray environment ideal for delicate roast profiles.

Humidity-Controlled Roast

Open roast pans allow for direct heat application, resulting in a drier roasting environment that enhances caramelization and crispiness but offers limited humidity control; in contrast, steam injection trays regulate moisture levels by introducing steam, preventing excessive drying and fostering even heat distribution for consistent roasting outcomes. Humidity-controlled roasting using steam injection trays improves flavor development and texture by maintaining optimal moisture balance throughout the roasting process.

Convective Steam Circulation

Convective steam circulation in open roast pans enhances even heat distribution but lacks the moisture control provided by steam injection trays, which inject precise steam bursts to maintain product juiciness and texture. Steam injection trays optimize roasting efficiency by promoting a uniform cooking environment through targeted humidity, reducing drying and improving flavor development compared to the more conventional convective heat flow of open roast pans.

Open-Air Evaporation Loss

Open roast pans increase open-air evaporation loss during roasting due to direct exposure of the product to ambient air, resulting in higher moisture loss and potential flavor alteration. Steam injection trays reduce open-air evaporation by introducing controlled steam, maintaining moisture content and enhancing roast uniformity while minimizing weight loss.

Open roast pan vs Steam injection tray for roasting. Infographic

cookingdiff.com

cookingdiff.com