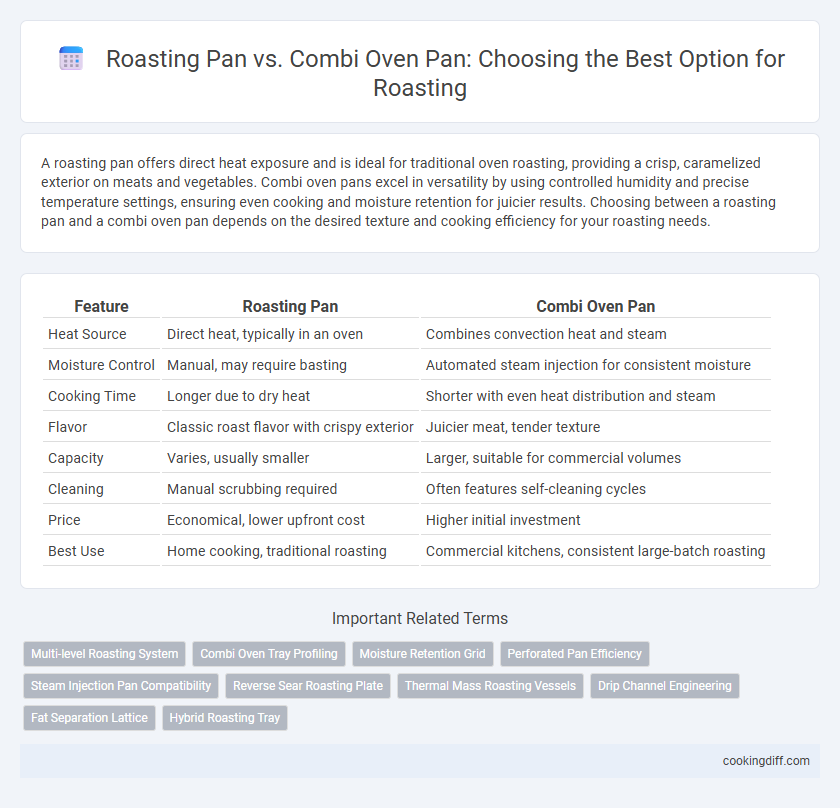

A roasting pan offers direct heat exposure and is ideal for traditional oven roasting, providing a crisp, caramelized exterior on meats and vegetables. Combi oven pans excel in versatility by using controlled humidity and precise temperature settings, ensuring even cooking and moisture retention for juicier results. Choosing between a roasting pan and a combi oven pan depends on the desired texture and cooking efficiency for your roasting needs.

Table of Comparison

| Feature | Roasting Pan | Combi Oven Pan |

|---|---|---|

| Heat Source | Direct heat, typically in an oven | Combines convection heat and steam |

| Moisture Control | Manual, may require basting | Automated steam injection for consistent moisture |

| Cooking Time | Longer due to dry heat | Shorter with even heat distribution and steam |

| Flavor | Classic roast flavor with crispy exterior | Juicier meat, tender texture |

| Capacity | Varies, usually smaller | Larger, suitable for commercial volumes |

| Cleaning | Manual scrubbing required | Often features self-cleaning cycles |

| Price | Economical, lower upfront cost | Higher initial investment |

| Best Use | Home cooking, traditional roasting | Commercial kitchens, consistent large-batch roasting |

Overview of Roasting Pans and Combi Oven Pans

Roasting pans are traditionally designed with deep sides and a rack to allow even heat circulation and fat drainage, ideal for roasting meats and vegetables. Combi oven pans, often made from durable materials like stainless steel or aluminum, are engineered to withstand the humid, controlled environment of combi ovens, promoting uniform cooking with moisture retention. While roasting pans excel in conventional oven settings, combi oven pans offer versatility by supporting multiple cooking methods such as steaming, roasting, and baking within a single appliance.

Material Differences: Roasting Pan vs Combi Oven Pan

Roasting pans are typically made from heavy-gauge stainless steel or cast iron to ensure even heat distribution and browning during traditional oven roasting. Combi oven pans are usually constructed from lightweight aluminum or anodized aluminum, designed to withstand high humidity and temperature fluctuations in combi ovens.

- Heat Conductivity - Roasting pans made from cast iron retain and distribute heat evenly, enhancing caramelization and crust formation.

- Moisture Resistance - Combi oven pans feature materials resistant to corrosion and moisture, suitable for steam injection environments.

- Durability - Stainless steel roasting pans offer durability and resistance to warping under dry heat, while combi pans prioritize lightweight yet sturdy materials to handle steam cycles.

Heat Distribution and Cooking Performance

Which pan offers better heat distribution for roasting, a roasting pan or a combi oven pan? Roasting pans typically provide direct heat with crispier results due to their solid metal construction, while combi oven pans ensure even heat distribution through steam and convection. The combi oven pan's moisture retention improves cooking performance by preventing drying and promoting uniform browning.

Versatility in Roasting Applications

The roasting pan offers excellent heat retention and is ideal for traditional oven roasting, ensuring even browning and crisp texture. Combi oven pans provide superior flexibility by supporting multiple cooking methods such as steaming, convection, and combination cooking for varied roasting applications.

- Roasting Pan Durability - Constructed from heavy-gauge materials, roasting pans withstand high oven temperatures for long periods without warping.

- Combi Oven Pan Functionality - Designed with perforations or solid bases to accommodate steam and dry heat, enabling precise moisture control during roasting.

- Versatility in Cooking Styles - Combi oven pans enhance efficiency by combining roasting with steaming and slow cooking, suitable for a wide range of proteins and vegetables.

Size and Capacity Comparison

The roasting pan typically offers a larger capacity with deeper sides, ideal for accommodating whole poultry or large cuts of meat. Sizes range from 16 to 20 inches in length, providing ample space for juices and drippings to collect during roasting.

Combi oven pans are usually shallower and more compact, designed to fit within the oven racks of commercial combi ovens. Their smaller size enhances heat circulation and allows for efficient cooking of multiple smaller portions simultaneously.

Ease of Use and Cleaning

Roasting pans offer a traditional approach with detachable racks that simplify handling but often require more scrubbing due to their porous surfaces. Combi oven pans typically feature non-stick coatings and smooth finishes, enhancing ease of cleaning and reducing residue buildup.

The design of combi oven pans promotes efficient heat distribution and allows for easy sliding in and out of the oven, improving user convenience during roasting. Roasting pans may demand more manual effort when cleaning, especially with stubborn drips or caramelized fats. Using a combi oven pan can save time and effort, making it ideal for busy kitchens prioritizing hygiene and operational efficiency.

Impact on Roasting Flavor and Texture

Roasting pans are designed to allow even heat circulation and fat drainage, enhancing the caramelization and crispiness of roasted meats, which intensifies flavor and improves texture. Combi oven pans offer controlled humidity levels that retain moisture, resulting in juicier and more tender roasts but potentially less crust formation. Choosing between these pans depends on whether the priority is a robust, crispy exterior or a moist, tender interior in the final roast.

Suitability for Different Oven Types

| Roasting Pan | Best suited for conventional ovens, offering excellent heat distribution and browning for meats and vegetables. Typically made from heavy-duty materials like stainless steel or cast iron, ensuring durability and optimal heat retention. Not ideal for combi ovens as they may not withstand the precise humidity control and steam injection. |

| Combi Oven Pan | Designed specifically for combi ovens, these pans handle high humidity and steam cycles without warping or corrosion. Usually constructed from aluminum or specialized non-stick coatings to maximize heat conduction and facilitate easy cleaning. Less suitable for traditional ovens due to different thermal requirements and moisture management. |

Cost Analysis: Roasting Pan vs Combi Oven Pan

Roasting pans generally have a lower initial purchase cost compared to combi oven pans, making them accessible for smaller operations. Combi oven pans, though pricier upfront, offer durability and versatility that can lead to long-term savings in high-volume settings.

- Initial Cost Difference - Roasting pans cost significantly less, averaging $20-$50 versus $150-$300 for combi oven pans.

- Durability - Combi oven pans are constructed from heavy-duty materials designed to withstand high heat and frequent use, reducing replacement frequency.

- Operational Savings - Combi oven pans improve cooking efficiency and reduce energy usage, potentially lowering utility expenses.

Choosing between a roasting pan and a combi oven pan requires analyzing both upfront costs and long-term operational benefits to determine the best investment.

Related Important Terms

Multi-level Roasting System

A multi-level roasting system enhances cooking efficiency by allowing simultaneous roasting of multiple dishes using a combi oven pan, which provides even heat distribution and moisture retention, unlike a traditional roasting pan that offers limited capacity and uneven heat exposure. Combi oven pans maximize space and consistency, ideal for commercial kitchens aiming to optimize roasting throughput and maintain superior product quality.

Combi Oven Tray Profiling

Combi oven pans feature advanced tray profiling that ensures even heat distribution and optimal moisture retention, enhancing the roasting process with precise temperature control and consistent browning. Unlike traditional roasting pans, these trays often have perforations and raised profiles that allow better air circulation and drip management, resulting in perfectly roasted meats and vegetables.

Moisture Retention Grid

A roasting pan with a moisture retention grid elevates meat, allowing juices to circulate and retain moisture while preventing sogginess, ideal for traditional roasting methods. In contrast, a combi oven pan often integrates steam technology and a perforated grid that enhances moisture retention through controlled humidity, delivering evenly cooked, tender results with reduced drying.

Perforated Pan Efficiency

Perforated roasting pans enhance airflow and heat circulation, promoting even cooking and crispier textures compared to traditional combi oven pans. Their design reduces moisture retention, resulting in superior browning and reduced cooking times in high-efficiency roasting environments.

Steam Injection Pan Compatibility

Roasting pans designed for traditional ovens often lack the steam injection compatibility found in combi oven pans, which are specifically engineered to withstand moisture and high pressure environments. Combi oven pans enhance roasting by allowing precise steam control, improving browning and moisture retention compared to standard roasting pans.

Reverse Sear Roasting Plate

Reverse sear roasting plates designed for combi oven pans offer superior heat distribution and moisture retention compared to traditional roasting pans, resulting in evenly cooked, tender meats with a perfectly caramelized crust. Their robust construction and compatibility with precise temperature controls in combi ovens enhance the efficiency and quality of reverse searing techniques, making them ideal for professional and home chefs seeking consistent roasting results.

Thermal Mass Roasting Vessels

Roasting pans with high thermal mass, such as heavy-duty cast iron or stainless steel, retain and evenly distribute heat, producing consistent browning and moisture retention in roast cooking. Combi oven pans, often made from lightweight aluminum or perforated materials, allow for rapid heat transfer and steam circulation, optimizing cooking speed and tenderness but sacrificing some thermal mass stability.

Drip Channel Engineering

Roasting pans with drip channel engineering are specifically designed to collect and separate juices away from the meat, enhancing browning and reducing excess fat during roasting. Combi oven pans, while versatile for steaming and convection cooking, often lack the specialized drip channels that optimize fat drainage and caramelization in roasting applications.

Fat Separation Lattice

Roasting pans with fat separation lattice feature elevated ridges that allow drippings and excess fat to drain away from the meat, resulting in healthier, crispier roasting outcomes. Combi oven pans often incorporate similar lattice designs combined with steam and convection technology, enhancing fat separation while ensuring even cooking and moisture retention.

Roasting Pan vs Combi Oven Pan for roasting. Infographic

cookingdiff.com

cookingdiff.com