Using a rolling pin for roasting evenly flattens the dough, ensuring consistent thickness and uniform cooking. A dough docker, with its spiked surface, prevents air bubbles by perforating the dough, which helps maintain an even texture during roasting. Choosing between the two depends on whether you prioritize smoothness with a rolling pin or bubble control with a dough docker for optimal roasting results.

Table of Comparison

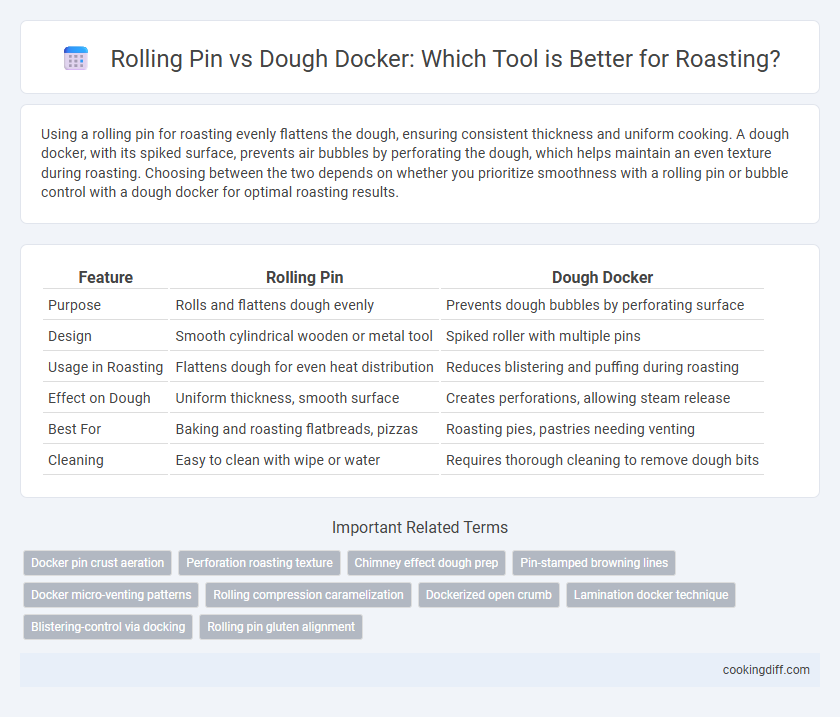

| Feature | Rolling Pin | Dough Docker |

|---|---|---|

| Purpose | Rolls and flattens dough evenly | Prevents dough bubbles by perforating surface |

| Design | Smooth cylindrical wooden or metal tool | Spiked roller with multiple pins |

| Usage in Roasting | Flattens dough for even heat distribution | Reduces blistering and puffing during roasting |

| Effect on Dough | Uniform thickness, smooth surface | Creates perforations, allowing steam release |

| Best For | Baking and roasting flatbreads, pizzas | Roasting pies, pastries needing venting |

| Cleaning | Easy to clean with wipe or water | Requires thorough cleaning to remove dough bits |

Introduction: Rolling Pin vs Dough Docker in Roasting

| Rolling Pin | Used to evenly flatten dough, creating a uniform thickness essential for consistent roasting and browning. |

| Dough Docker | Equipped with spiked rollers, it pierces the dough to prevent bubbles and uneven air pockets during roasting, ensuring a flat and crispy texture. |

| Comparison | While rolling pins shape the dough, dough dockers specifically improve texture by controlling air escape, both critical for optimal roasting results. |

Understanding the Tools: Rolling Pin and Dough Docker Defined

A rolling pin is a handheld kitchen tool used to flatten and shape dough evenly, crucial for uniform thickness in roasting preparations. A dough docker is a specialized tool with a spiked roller designed to puncture dough surfaces, preventing bubbles and uneven cooking during roasting. Understanding these tools helps optimize dough texture and consistency in roasting recipes.

How Each Tool Affects Roasting Outcomes

The rolling pin evenly flattens dough, promoting uniform thickness that ensures consistent roasting and crispness. In contrast, a dough docker punctures the dough surface, preventing air bubbles and uneven rising that can lead to inconsistent roasting textures. Using a rolling pin results in a smooth, crisp roast, while a dough docker enhances texture by minimizing bloating during roasting.

Texture and Evenness: Rolling Pin Advantages

How does a rolling pin impact the texture and evenness of roasted dough compared to a dough docker? A rolling pin provides greater control over dough thickness, resulting in a more uniform texture ideal for roasting. This tool allows for consistent pressure, which helps achieve an evenly roasted surface without unwanted air pockets.

Maximizing Airflow: Benefits of the Dough Docker

Using a dough docker over a rolling pin significantly enhances airflow during roasting by creating consistent perforations in the dough. These holes prevent air bubbles from forming, resulting in a more even roast and crispier texture.

The dough docker's design maximizes ventilation by evenly distributing small holes throughout the dough surface, which the rolling pin cannot achieve. Improved airflow reduces undercooked spots and eliminates puffiness, promoting uniform heat penetration. This technique is essential for achieving professional-quality roasting results in products like pizza and flatbreads.

When to Use a Rolling Pin for Roasting Preparations

A rolling pin is ideal for evenly flattening dough when preparing roasted dishes like flatbreads or pizza crusts. It ensures consistent thickness, which promotes uniform cooking and crispiness during roasting.

- Thickness Control - A rolling pin allows precise control over dough thickness, essential for recipes requiring even roasting.

- Versatility - It can be used on various dough types, including bread, pastry, and pastry-based roasting preparations.

- Smoother Surface - Rolling pins create a smooth dough surface, improving heat distribution and texture in roasted foods.

When a Dough Docker Improves Roasting Results

A dough docker creates uniform perforations in dough, preventing large air bubbles that cause uneven roasting and inconsistent texture. This tool enhances heat distribution, resulting in a crispier, more evenly browned crust compared to using a rolling pin alone.

Rolling pins flatten dough but do not address trapped air, which can lead to puffed or unevenly baked areas during roasting. Employing a dough docker improves dough structure, making it ideal for high-temperature roasting where consistent heat exposure is critical.

Key Differences: Rolling Pin vs Dough Docker in Roasting

The key difference between a rolling pin and a dough docker in roasting lies in their functionality: a rolling pin is primarily used to flatten dough to an even thickness, while a dough docker punctures the dough to prevent air bubbles during baking. In roasting applications, a dough docker helps create uniformly textured crusts by ensuring even heat distribution.

Rolling pins provide smooth surfaces essential for shaping and preparing dough before roasting, facilitating consistent thickness and better cooking results. Dough dockers, with their spiked rollers, are specialized tools designed to enhance roasting outcomes by promoting even browning and texture in baked goods.

Common Mistakes with Each Tool during Roasting

Using a rolling pin for roasting-related dough preparation often leads to uneven thickness, which affects consistent cooking. Dough dockers, while designed to prevent bubbling, can cause over-piercing if not used carefully, resulting in dry, tough textures.

- Rolling Pin Overuse - Excessive rolling can make dough too thin, causing it to burn during roasting.

- Dough Docker Overpressure - Pressing too hard can tear the dough, compromising its structure and roasting quality.

- Incorrect Tool Selection - Choosing a rolling pin instead of a dough docker may lead to insufficient air release and uneven roasting outcomes.

Related Important Terms

Docker pin crust aeration

A dough docker is designed to perforate the dough surface, allowing steam to escape and preventing uneven bubbling, which results in a crust with uniform aeration essential for proper roasting. In contrast, a rolling pin lacks this functionality, often causing inconsistent venting and less controlled crust texture during roasting.

Perforation roasting texture

A dough docker creates uniform perforations that allow steam to escape during roasting, preventing uneven puffing and ensuring a crisp, consistent texture. In contrast, a rolling pin lacks the ability to perforate dough effectively, often resulting in irregular air pockets and a less desirable roast texture.

Chimney effect dough prep

Using a dough docker creates uniform perforations that prevent excess air bubbles and maintain consistent thickness, enhancing the chimney effect in roasting by allowing heat to circulate evenly through the dough. In contrast, a rolling pin flattens the dough without perforations, which can trap air pockets and disrupt the airflow necessary for optimal roasting results.

Pin-stamped browning lines

A rolling pin creates uniform pin-stamped browning lines by evenly pressing the dough, enhancing caramelization and texture during roasting. In contrast, a dough docker perforates the dough to prevent excessive puffing but does not produce the distinctive browning patterns formed by rolling pins.

Docker micro-venting patterns

Dough dockers create micro-venting patterns that prevent large air bubbles during roasting, ensuring even heat distribution and consistent crust texture. Rolling pins lack these specialized perforations, often resulting in uneven puffing and less controlled roasting outcomes.

Rolling compression caramelization

Rolling pins apply consistent compression to dough, promoting even caramelization by flattening the surface and enabling uniform heat exposure during roasting. Dough dockers create perforations that release gas but do not enhance caramelization through compression, making rolling pins more effective for achieving a golden, caramelized crust.

Dockerized open crumb

A dough docker creates uniform perforations that prevent large air pockets, promoting a consistently open crumb ideal for roasting applications, while a rolling pin may compress the dough unevenly, risking dense spots. Dockerized dough ensures controlled gas release during proofing and baking, resulting in a crisp, evenly roasted crust with a light, airy interior.

Lamination docker technique

The lamination docker technique enhances dough texture during roasting by evenly piercing the dough to prevent air bubbles, compared to a rolling pin that primarily flattens dough without creating perforations. Using a dough docker optimizes heat distribution and structural integrity in laminated roasted products, making it superior for achieving consistent puff and crispness.

Blistering-control via docking

A dough docker provides precise blistering control during roasting by creating uniform perforations that allow steam to escape evenly, preventing excessive puffing and uneven cooking. In contrast, a rolling pin lacks this indented patterning, resulting in less effective docking and potential for irregular blister formation on the roasted dough surface.

Rolling pin vs dough docker for roasting. Infographic

cookingdiff.com

cookingdiff.com