Roasting prime rib in a traditional oven allows for a consistent, dry heat that enhances the crust's caramelization and deepens flavor complexity. Combi-oven roasting offers precise temperature and humidity control, which ensures even cooking and moisture retention, resulting in a tender, juicy prime rib. Choosing between the two methods depends on the desired texture and flavor profile, with combi-oven roasting excelling in uniform tenderness and classic roasting highlighting a robust crust.

Table of Comparison

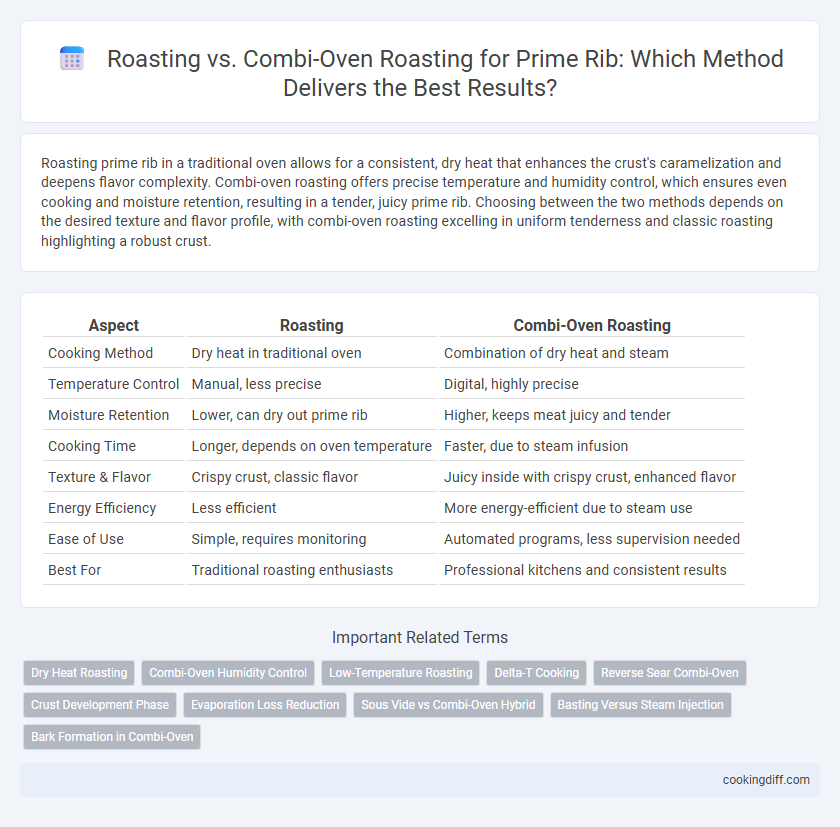

| Aspect | Roasting | Combi-Oven Roasting |

|---|---|---|

| Cooking Method | Dry heat in traditional oven | Combination of dry heat and steam |

| Temperature Control | Manual, less precise | Digital, highly precise |

| Moisture Retention | Lower, can dry out prime rib | Higher, keeps meat juicy and tender |

| Cooking Time | Longer, depends on oven temperature | Faster, due to steam infusion |

| Texture & Flavor | Crispy crust, classic flavor | Juicy inside with crispy crust, enhanced flavor |

| Energy Efficiency | Less efficient | More energy-efficient due to steam use |

| Ease of Use | Simple, requires monitoring | Automated programs, less supervision needed |

| Best For | Traditional roasting enthusiasts | Professional kitchens and consistent results |

Introduction: Prime Rib Perfection

| Roasting prime rib using traditional dry heat preserves the meat's natural flavors and creates a flavorful crust with a tender interior. Combi-oven roasting combines dry heat and steam, ensuring even cooking and enhanced moisture retention for a juicier prime rib. Selecting the right method depends on the desired texture, cooking time, and flavor intensity for prime rib perfection. |

Understanding Traditional Roasting

Traditional roasting of prime rib uses dry heat, typically in an oven set between 225degF and 250degF, allowing the meat to cook evenly while developing a browned crust. This method emphasizes slow cooking to maintain juiciness and tenderness by rendering fat gradually without steaming the meat.

- Heat Source - Uses dry, consistent heat from an oven to promote Maillard reaction and crust formation.

- Cooking Time - Requires longer cooking time at lower temperatures for juicy, tender prime rib.

- Flavor Profile - Enhances natural beef flavors and texture through gradual moisture loss and crust development.

Exploring Combi-Oven Roasting Techniques

Combi-oven roasting integrates steam and dry heat to enhance prime rib tenderness while preserving moisture. This method offers precise temperature control, reducing the risk of overcooking compared to traditional roasting.

- Moisture Retention - Steam injected in combi-ovens maintains juiciness by preventing surface drying during roasting.

- Even Cooking - The combination of steam and dry heat ensures consistent internal temperature throughout the prime rib.

- Versatile Cooking Profiles - Combi-ovens allow customization of humidity and heat settings optimized for different cuts and textures.

Comparing Cooking Times and Temperatures

Roasting prime rib in a traditional oven typically requires cooking at a steady temperature of 325degF for about 15-20 minutes per pound, ensuring even heat distribution and a crusty exterior. In contrast, combi-oven roasting combines steam and dry heat, allowing for more precise temperature control, often reducing cooking times by up to 25% without compromising flavor.

Traditional roasting relies on consistent dry heat, usually reaching internal temperatures around 130degF for medium-rare, whereas combi-ovens maintain humidity to prevent drying, enabling cooking at slightly lower temperatures around 300degF. The integration of steam in combi-oven roasting also enhances moisture retention, resulting in juicier prime rib compared to the conventional dry roasting method.

Moisture Retention: Traditional vs Combi-Oven

How does moisture retention differ between traditional roasting and combi-oven roasting for prime rib? Traditional roasting often results in more moisture loss due to dry heat exposure, which can cause the exterior to dry out before the interior reaches the desired temperature. Combi-oven roasting uses controlled humidity and steam injection to maintain a juicier prime rib by reducing evaporation and preserving internal moisture.

Flavor Development and Crust Formation

Traditional roasting of prime rib promotes superior flavor development due to the Maillard reaction occurring at higher, consistent heat levels, enhancing the meat's natural umami and caramelized notes. This process also ensures a well-defined crust formation, contributing to an appealing texture contrast and intensified savory profile.

Combi-oven roasting combines steam and dry heat, which can result in a juicier prime rib by preventing excessive moisture loss but may inhibit the full development of a robust crust and complex flavors. While efficient, the gentler cooking environment often produces a less pronounced sear compared to conventional roasting, impacting the crust's crispness and depth of flavor.

Consistency and Doneness Control

Roasting prime rib in a traditional oven often results in uneven cooking due to fluctuating temperatures and variable heat exposure. Combi-oven roasting offers superior consistency and precise doneness control by combining steam and dry heat, which ensures even heat distribution and moisture retention. This technology minimizes the risk of overcooking or undercooking, delivering perfectly cooked prime rib every time.

Equipment and Energy Considerations

Traditional roasting of prime rib requires a conventional oven that maintains consistent dry heat, which can lead to higher energy consumption over longer cook times. Combi-oven roasting integrates steam and dry heat, offering precise temperature control and significantly reducing energy usage by speeding up cooking times while retaining moisture. Equipment costs for combi-ovens are higher upfront, but their energy efficiency and versatility make them a cost-effective choice in commercial kitchens focused on prime rib preparation.

Pros and Cons of Each Method

Traditional roasting of prime rib delivers a rich crust and deep flavor through dry heat, while combi-oven roasting offers precise temperature and humidity control to enhance juiciness. Each method carries distinct advantages and drawbacks affecting texture, cooking time, and overall taste.

- Traditional Roasting - Provides a classic caramelized crust but may risk uneven cooking and longer preparation time.

- Combi-Oven Roasting - Maintains moisture through humidity control, ensuring even cooking but can result in less crust development.

- Flavor and Texture - Roasting develops a more intense flavor profile, whereas combi-oven roasting emphasizes tenderness and juiciness.

Choosing between methods depends on desired texture, flavor, and operational efficiency in cooking prime rib.

Related Important Terms

Dry Heat Roasting

Dry heat roasting of prime rib in a traditional oven emphasizes Maillard reaction for a deeply caramelized crust, while combi-oven roasting combines dry heat and steam to enhance juiciness and consistency. Prime rib roasted solely with dry heat typically results in a more pronounced crust and richer flavor profile due to direct convection and radiant heat exposure.

Combi-Oven Humidity Control

Combi-oven roasting offers precise humidity control essential for prime rib, maintaining juiciness by preventing moisture loss while achieving an even crust. This controlled environment reduces shrinkage and enhances tenderness compared to traditional dry roasting methods.

Low-Temperature Roasting

Low-temperature roasting of prime rib preserves juiciness and enhances tenderness by cooking evenly at around 225degF to 275degF, minimizing moisture loss. Combi-oven roasting combines precise humidity and temperature control, accelerating cooking times while maintaining a consistent, succulent texture ideal for large cuts like prime rib.

Delta-T Cooking

Delta-T cooking in roasting prime rib ensures precise temperature control by maintaining a consistent difference between the air and meat temperatures, resulting in evenly cooked, tender meat. Compared to combi-oven roasting, traditional roasting with Delta-T prioritizes gradual heat penetration, reducing overcooking and moisture loss while enhancing flavor development through Maillard reactions.

Reverse Sear Combi-Oven

Reverse sear combi-oven roasting for prime rib combines precise humidity and temperature control to deliver even cooking and optimal moisture retention, enhancing tenderness compared to traditional dry roasting methods. This technique allows for consistent internal doneness while developing a flavorful crust, reducing the risk of overcooking and improving overall texture.

Crust Development Phase

Roasting prime rib in a traditional oven promotes a slower Maillard reaction, resulting in a thicker, more flavorful crust with enhanced caramelization. Combi-oven roasting offers precise humidity control, which can optimize crust development by balancing moisture retention and browning intensity for a consistently tender interior and evenly crisp exterior.

Evaporation Loss Reduction

Combi-oven roasting significantly reduces evaporation loss during prime rib cooking by maintaining precise humidity control, preserving more moisture within the meat. Traditional roasting methods result in higher evaporation rates due to dry heat exposure, leading to greater shrinkage and less juicy prime rib.

Sous Vide vs Combi-Oven Hybrid

Sous vide prime rib cooking ensures precise temperature control and even doneness throughout the meat, while the combi-oven roasting hybrid method combines moisture and convection heat to develop a well-browned crust without overcooking. This hybrid approach enhances flavor and texture by finishing the sous vide-prepared prime rib with a high-heat blast in the combi-oven, optimizing juiciness and crust formation.

Basting Versus Steam Injection

Roasting prime rib relies on continuous basting to enhance flavor and maintain moisture, creating a rich, caramelized crust through direct dry heat. Combi-oven roasting uses steam injection to regulate humidity, preserving juiciness and tenderness without the need for manual basting, resulting in consistent cooking and an evenly browned exterior.

Roasting vs Combi-Oven Roasting for prime rib. Infographic

cookingdiff.com

cookingdiff.com