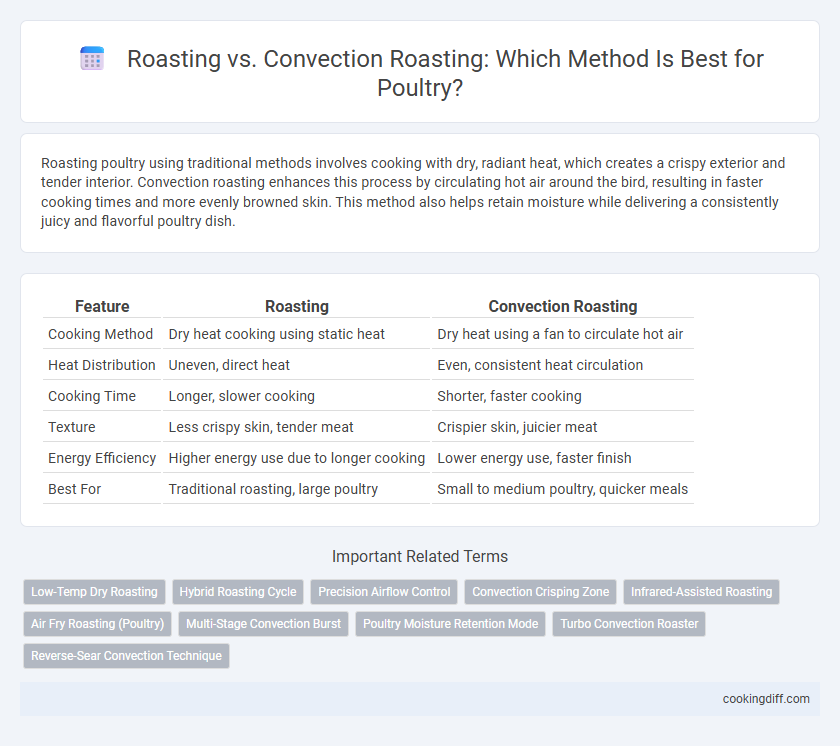

Roasting poultry using traditional methods involves cooking with dry, radiant heat, which creates a crispy exterior and tender interior. Convection roasting enhances this process by circulating hot air around the bird, resulting in faster cooking times and more evenly browned skin. This method also helps retain moisture while delivering a consistently juicy and flavorful poultry dish.

Table of Comparison

| Feature | Roasting | Convection Roasting |

|---|---|---|

| Cooking Method | Dry heat cooking using static heat | Dry heat using a fan to circulate hot air |

| Heat Distribution | Uneven, direct heat | Even, consistent heat circulation |

| Cooking Time | Longer, slower cooking | Shorter, faster cooking |

| Texture | Less crispy skin, tender meat | Crispier skin, juicier meat |

| Energy Efficiency | Higher energy use due to longer cooking | Lower energy use, faster finish |

| Best For | Traditional roasting, large poultry | Small to medium poultry, quicker meals |

Introduction to Roasting and Convection Roasting

Roasting is a dry heat cooking method that surrounds poultry with hot air to cook it evenly, developing a crispy skin and juicy interior. Convection roasting enhances this process by using a fan to circulate hot air, leading to faster and more uniform cooking.

Traditional roasting relies on radiant heat from the oven walls, which can result in uneven cooking if the air does not circulate well. Convection roasting uses a built-in fan to distribute heat consistently around the poultry, reducing cooking time by up to 25%. This method also helps render fat more effectively, producing a crisper texture and more flavorful meat.

Understanding Traditional Roasting for Poultry

Traditional roasting for poultry relies on dry heat that surrounds the bird evenly, resulting in a crisp skin and juicy interior. This method uses radiant heat typically from an oven's heating element, allowing the meat to cook slowly and develop rich flavors. Understanding the importance of maintaining proper temperature and basting helps enhance moisture retention and tenderness during roasting.

What is Convection Roasting?

Convection roasting uses a fan to circulate hot air evenly around poultry, ensuring faster and more uniform cooking compared to traditional roasting. This technique helps achieve a crispier skin while keeping the meat juicy due to consistent heat distribution.

- Enhanced Heat Circulation - The fan in convection roasting promotes even heat flow, reducing hot spots and cooking time.

- Crispier Skin - Increased air movement removes moisture effectively, resulting in a golden, crispy exterior on poultry.

- Juicier Meat - Consistent temperature maintains moisture inside while cooking poultry thoroughly.

Key Differences Between Roasting and Convection Roasting

What are the key differences between roasting and convection roasting for poultry? Roasting uses radiant heat from an oven's heating element, while convection roasting utilizes a fan to circulate hot air, resulting in more even cooking. Convection roasting typically reduces cooking time and promotes crispier skin compared to traditional roasting.

Heat Circulation: Standard Oven vs. Convection Oven

Standard ovens rely on radiant heat from the heating elements, resulting in uneven heat distribution when roasting poultry. Convection ovens use a fan to circulate hot air, promoting consistent heat and faster cooking times.

- Standard Oven Heat Distribution - Heat rises naturally and stays uneven, causing potential hot spots in poultry roasting.

- Convection Oven Air Circulation - The fan evenly disperses heat around the poultry, improving browning and crispiness.

- Cooking Efficiency - Convection ovens reduce cooking time by up to 25% compared to standard ovens due to better heat circulation.

Impact on Poultry Texture and Juiciness

Roasting poultry using traditional dry heat results in a crispy skin while potentially drying out the interior if not carefully monitored. The slow, indirect heat allows collagen in the meat to break down, enhancing tenderness but sometimes sacrificing juiciness.

Convection roasting circulates hot air with a fan, promoting more even cooking and faster heat transfer to the poultry's surface. This method helps retain moisture inside the meat, producing a juicier texture and crispier skin compared to conventional roasting.

Cooking Time and Temperature Adjustments

Roasting poultry requires maintaining an oven temperature of around 350degF (175degC) for an even cook, while convection roasting utilizes a fan to circulate hot air, allowing temperatures to be reduced to 325degF (163degC). This circulation shortens cooking time by approximately 25%, ensuring the poultry remains juicy with a crispy exterior.

Adjust cooking time for convection roasting by reducing it to about 75% of the conventional roasting duration; for example, a 60-minute roast becomes 45 minutes. Monitoring internal temperature is crucial, with poultry needing to reach 165degF (74degC) to ensure safety regardless of roasting method.

Flavor Development in Roasting vs. Convection Roasting

Roasting poultry using traditional methods allows for slow, even heat that enhances natural flavors and promotes deep caramelization. Convection roasting circulates hot air, speeding up cooking time while creating a crispy exterior but can sometimes reduce flavor complexity.

- Flavor Intensity - Traditional roasting develops richer, more nuanced flavors through gradual Maillard reactions.

- Crispiness - Convection roasting excels at producing a uniformly crispy skin due to consistent hot air flow.

- Moisture Retention - Slow roasting helps retain juiciness inside the poultry, contributing to a fuller taste profile.

Choosing between roasting and convection roasting depends on desired flavor depth and cooking efficiency.

Best Practices for Each Method

| Roasting | Ideal for whole poultry, dry heat at 325degF to 375degF evenly cooks meat while rendering fat; best practice includes seasoning cavity, using a rack to ensure even air circulation, and basting occasionally for moisture retention. |

| Convection Roasting | Uses fan-forced heat to circulate hot air at slightly lower temperatures (300degF to 350degF), promoting faster, more even cooking; recommended to reduce cooking time by 25%, avoid over-browning by tenting with foil if needed, and adjust seasoning as air circulation intensifies flavor absorption. |

Related Important Terms

Low-Temp Dry Roasting

Low-temp dry roasting in poultry ensures even heat penetration, preserving moisture and producing tender, flavorful meat without drying out the skin. Compared to convection roasting, which uses a fan to circulate hot air for faster cooking, low-temp dry roasting offers superior control over internal doneness and minimizes risk of overcooking.

Hybrid Roasting Cycle

Hybrid roasting cycles combine traditional roasting with convection heat, ensuring uniformly crisp skin and juicy meat in poultry by optimizing heat distribution. This method reduces cooking time by up to 25% compared to conventional roasting while maintaining the rich flavors developed through slower heat exposure.

Precision Airflow Control

Roasting poultry using convection ovens offers precise airflow control that evenly distributes hot air, ensuring consistent cooking and crisp skin compared to traditional roasting methods. This controlled air circulation reduces cooking time and prevents uneven heat spots, resulting in juicier meat and a perfectly browned exterior.

Convection Crisping Zone

Convection roasting enhances poultry by circulating hot air around the bird, creating a Convection Crisping Zone that ensures even browning and a crispy exterior while locking in juicy flavors. This method outperforms traditional roasting by reducing cooking time and producing consistently tender meat with a perfectly crisp skin.

Infrared-Assisted Roasting

Infrared-assisted roasting enhances poultry cooking by using infrared radiation to penetrate the meat, resulting in faster heat transfer and evenly browned skin compared to traditional convection roasting, which relies primarily on hot air circulation. This method reduces cooking time, preserves juiciness, and improves flavor development while maintaining a crisp texture on poultry surfaces.

Air Fry Roasting (Poultry)

Air fry roasting poultry uses high-speed hot air circulation to achieve a crispy skin and juicy interior faster than conventional roasting, which relies on radiant heat without airflow. This convection-based method reduces cooking time and fat content while enhancing even browning and moisture retention in poultry.

Multi-Stage Convection Burst

Multi-stage convection burst in roasting enhances poultry by alternating high-intensity heat with controlled convection airflow, ensuring even cooking and crisp skin while maintaining juiciness. This method outperforms traditional roasting by reducing cooking time and preventing moisture loss through dynamic heat cycles tailored to poultry's unique texture and composition.

Poultry Moisture Retention Mode

Roasting poultry preserves moisture by cooking at moderate, consistent temperatures, while convection roasting uses a fan to circulate hot air, promoting faster cooking but potentially leading to drier results if not carefully monitored. Poultry moisture retention is typically higher in traditional roasting due to slower heat penetration, which allows juices to stay locked within the meat fibers.

Turbo Convection Roaster

Turbo convection roasting uses a powerful fan to circulate hot air around poultry, ensuring even browning and faster cooking compared to traditional roasting methods. This method enhances flavor retention and moisture by providing consistent heat distribution, resulting in juicier, crispier poultry.

Roasting vs Convection Roasting for poultry. Infographic

cookingdiff.com

cookingdiff.com