An oven thermometer provides consistent internal temperature readings by being placed inside the oven, ensuring the entire oven environment is accurately monitored during pet roasting. Infrared probes measure surface temperature instantly, offering quick spot checks but may not reflect the true internal heat critical for thorough cooking. For precise roasting results, combining both tools optimizes temperature control and prevents under- or overcooking your pet delicacies.

Table of Comparison

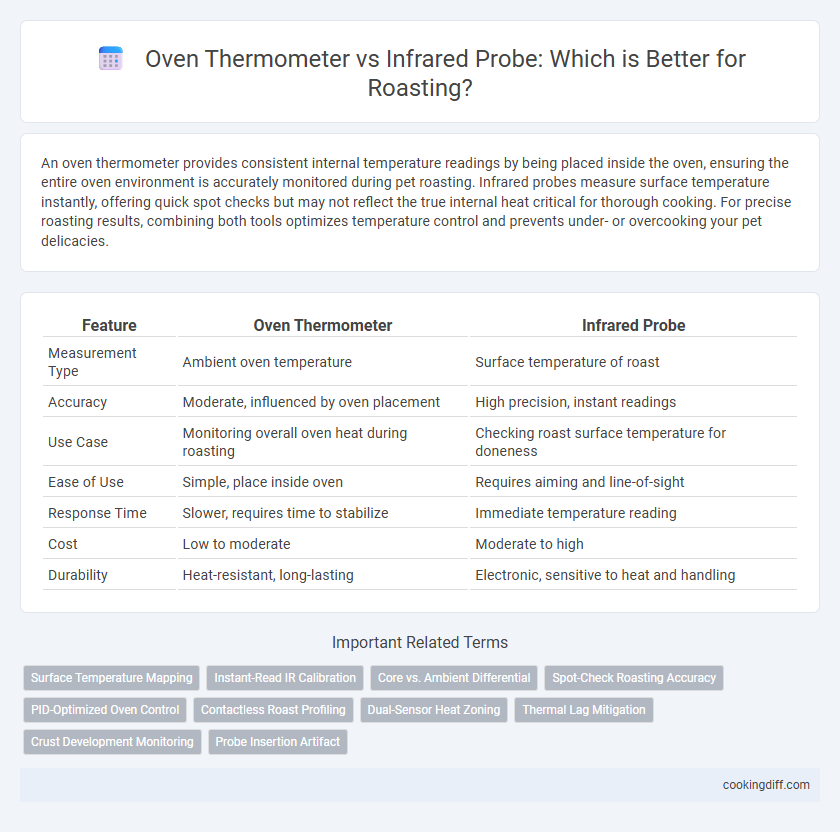

| Feature | Oven Thermometer | Infrared Probe |

|---|---|---|

| Measurement Type | Ambient oven temperature | Surface temperature of roast |

| Accuracy | Moderate, influenced by oven placement | High precision, instant readings |

| Use Case | Monitoring overall oven heat during roasting | Checking roast surface temperature for doneness |

| Ease of Use | Simple, place inside oven | Requires aiming and line-of-sight |

| Response Time | Slower, requires time to stabilize | Immediate temperature reading |

| Cost | Low to moderate | Moderate to high |

| Durability | Heat-resistant, long-lasting | Electronic, sensitive to heat and handling |

Introduction to Temperature Accuracy in Roasting

Accurate temperature measurement is crucial in roasting to achieve consistent and precise results. Oven thermometers and infrared probes are two common tools used to monitor roasting temperatures effectively.

Oven thermometers provide a direct reading of the ambient temperature inside the oven, helping to maintain a stable roasting environment. Infrared probes measure the surface temperature of the food, offering rapid and non-contact readings that can detect hot spots or uneven heating. Choosing the appropriate device depends on the specific needs of the roasting process and the level of temperature control required.

How Oven Thermometers Work

Oven thermometers measure the ambient temperature inside the oven by using a bimetallic coil or liquid-filled sensor that expands or contracts based on heat. These devices provide continuous temperature readings to ensure accurate roasting conditions throughout the cooking process.

- Bimetallic Coil Sensor - Uses two different metals bonded together that expand at different rates as the oven heats, causing the needle to move on the dial.

- Liquid-Filled Bulb - Contains mercury or alcohol that expands with heat, rising in a glass tube to indicate temperature.

- Stable Ambient Readings - Measures the overall oven environment rather than surface temperature, ensuring consistent heat for roasting precision.

Understanding Infrared Probes in Cooking

Infrared probes measure surface temperature by detecting emitted infrared radiation, providing instant readings ideal for monitoring roasting progress without contact. Unlike oven thermometers that gauge ambient oven temperature, infrared devices focus on the food's exterior heat, enabling precise control over browning and caramelization.

- Surface temperature monitoring - Infrared probes accurately assess the external heat of roasting items for optimal searing.

- Non-contact measurement - These devices offer hygienic, instant readings without piercing the food's surface.

- Temperature precision - Infrared probes help prevent overcooking by providing localized heat data distinct from oven air temperature.

Precision and Reliability: Comparing the Tools

| Tool | Precision | Reliability |

|---|---|---|

| Oven Thermometer | Provides consistent ambient temperature readings within the oven cavity, crucial for maintaining steady roasting conditions. | Highly reliable for monitoring overall oven temperature but may not reflect the internal doneness of the roast. |

| Infrared Probe | Measures surface temperature instantly with high accuracy, allowing immediate adjustment to roasting profiles. | Less reliable for internal core temperature; best suited for monitoring exterior doneness and spotting hot spots. |

Ease of Use in the Kitchen

Oven thermometers provide consistent, easy-to-read temperature readings by simply placing them inside the oven, requiring minimal setup or technical knowledge. Infrared probes offer instant surface temperature measurements, making them ideal for quick checks but demand more careful handling to ensure accuracy.

Using an oven thermometer is straightforward, allowing cooks to monitor ambient oven heat continuously without opening the door, preserving heat stability. Infrared probes require aiming and steady positioning, which can be less convenient during fast-paced roasting processes in busy kitchens.

Versatility for Different Types of Roasts

Oven thermometers provide consistent ambient temperature readings, making them ideal for roasting large cuts like whole chickens or turkeys where steady heat is crucial. Infrared probes offer precise surface temperature measurements, enhancing versatility for searing or roasting smaller items such as steaks or vegetables. Combining both tools ensures optimal control across various roasting methods and ingredients for perfect culinary results.

Speed of Temperature Readings

Which device provides faster temperature readings for roasting: an oven thermometer or an infrared probe? Infrared probes deliver near-instantaneous temperature measurements by detecting surface heat without contact, ideal for quick adjustments during roasting. In contrast, oven thermometers require more time to stabilize, as they measure ambient air temperature inside the oven.

Maintenance and Calibration Needs

Oven thermometers require minimal maintenance but need regular calibration to ensure accurate temperature readings, often done by comparing with boiling or freezing point references. Infrared probes demand careful handling and frequent recalibration because their sensors can drift over time, affecting precision. Consistent calibration schedules for both devices improve roasting results by maintaining reliable temperature measurements.

Price and Value Considerations

Oven thermometers are generally more affordable, offering reliable temperature readings for budget-conscious roasters. Infrared probes tend to be pricier but provide precise, instant surface temperature measurements, enhancing roast control.

- Cost Efficiency - Oven thermometers usually cost less, making them accessible for home use without sacrificing basic accuracy.

- Precision vs Price - Infrared probes justify higher prices through advanced technology that allows quick, non-contact temperature checks.

- Value for Purpose - Choosing between the two depends on the level of roasting accuracy and investment one is willing to make.

Balancing price and functionality helps roasting enthusiasts select the best tool for their specific needs and budget.

Related Important Terms

Surface Temperature Mapping

Oven thermometers provide accurate ambient temperature readings essential for consistent roasting environments, while infrared probes excel in surface temperature mapping by delivering instantaneous, non-contact heat measurements of the food's exterior. Utilizing infrared probes allows precise monitoring of roasting surface temperatures, enabling better control over Maillard reactions and caramelization.

Instant-Read IR Calibration

Infrared probe thermometers provide instant-read temperature measurements essential for precise roasting control, while conventional oven thermometers require calibration to ensure consistent results within the oven environment. Accurate IR calibration aligns surface temperature readings with internal roast conditions, optimizing roast profiles and preventing overcooking or under-roasting.

Core vs. Ambient Differential

Oven thermometers measure ambient temperature, providing consistent data on the roasting environment, while infrared probes accurately gauge the core temperature of the food, offering precise control over doneness. The core versus ambient temperature differential is critical for roasting, as it affects cooking times and the final texture, with infrared probes enabling adjustments based on the internal heat rather than just the surrounding oven conditions.

Spot-Check Roasting Accuracy

Oven thermometers provide consistent ambient temperature readings, ensuring stable oven conditions during roasting, while infrared probes deliver instantaneous surface temperature measurements for precise spot-checking of food doneness. Combining both devices enhances roasting accuracy by monitoring oven environment and verifying exact food temperatures in real time.

PID-Optimized Oven Control

PID-optimized oven control enhances roasting precision by continuously adjusting heat based on real-time temperature feedback, where oven thermometers measure ambient oven temperature for stable heat regulation, while infrared probes provide rapid surface temperature readings critical for monitoring roast development. Combining the stability of oven thermometers with the responsiveness of infrared probes allows for optimal temperature control, reducing roast variability and improving flavor consistency.

Contactless Roast Profiling

Infrared probe thermometers provide precise, contactless roast profiling by measuring the surface temperature of coffee beans without heat loss or contamination, unlike oven thermometers that require physical contact and often produce slower, less accurate readings. Utilizing infrared technology enables roasters to capture real-time temperature fluctuations, enhancing control over roast profiles and improving overall coffee quality.

Dual-Sensor Heat Zoning

Oven thermometers provide consistent ambient temperature readings inside the roasting chamber, while infrared probes offer precise surface temperature measurements of the meat, enabling accurate control of dual-sensor heat zoning. Combining these sensors optimizes roasting by balancing oven air temperature with the exact internal surface heat of the food, resulting in evenly cooked, perfectly roasted dishes.

Thermal Lag Mitigation

An oven thermometer provides continuous temperature monitoring inside the oven, allowing for accurate detection of thermal lag and enabling adjustments to roasting time and temperature. Infrared probes measure surface temperature instantly, reducing thermal lag effects by offering real-time external readings, but may require calibration to align with internal meat temperatures for precise roast results.

Crust Development Monitoring

An oven thermometer provides consistent ambient temperature readings essential for maintaining stable roasting conditions, while an infrared probe offers precise surface temperature measurements critical for monitoring crust development in real-time. Combining both tools enhances control over Maillard reactions, ensuring optimal crust color and texture during roasting.

Oven Thermometer vs Infrared Probe for roasting. Infographic

cookingdiff.com

cookingdiff.com