A standard roasting rack allows even heat circulation around the entire surface of the pet, promoting consistent browning and crispiness. Vertical roasters help drain excess fat away from the pet, resulting in a juicier and less greasy outcome. Choosing between the two depends on whether you prioritize thorough heat exposure or fat reduction during roasting.

Table of Comparison

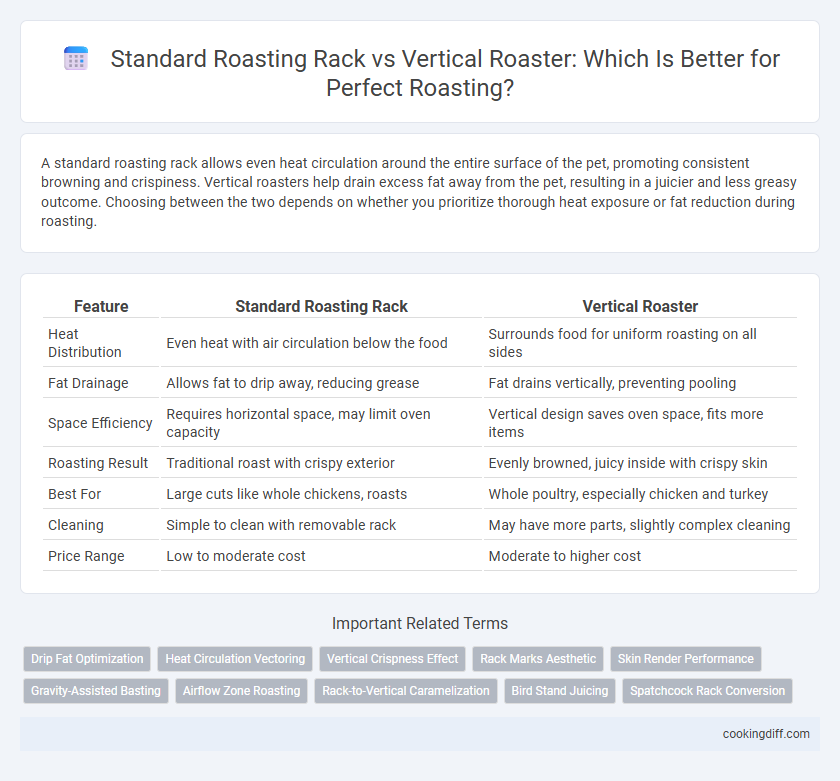

| Feature | Standard Roasting Rack | Vertical Roaster |

|---|---|---|

| Heat Distribution | Even heat with air circulation below the food | Surrounds food for uniform roasting on all sides |

| Fat Drainage | Allows fat to drip away, reducing grease | Fat drains vertically, preventing pooling |

| Space Efficiency | Requires horizontal space, may limit oven capacity | Vertical design saves oven space, fits more items |

| Roasting Result | Traditional roast with crispy exterior | Evenly browned, juicy inside with crispy skin |

| Best For | Large cuts like whole chickens, roasts | Whole poultry, especially chicken and turkey |

| Cleaning | Simple to clean with removable rack | May have more parts, slightly complex cleaning |

| Price Range | Low to moderate cost | Moderate to higher cost |

Introduction to Roasting Methods: Standard Rack vs. Vertical Roaster

Standard roasting racks evenly elevate food, allowing heat to circulate around the item for consistent cooking. This method is ideal for roasting larger cuts of meat or whole poultry, ensuring even browning and moisture retention.

Vertical roasters position the food upright, which promotes better fat drainage and crispier skin, especially for poultry. This technique enhances air flow and results in juicier, evenly cooked meat with a distinct texture.

Design Differences: Standard Roasting Rack vs. Vertical Roaster

The standard roasting rack features a horizontal design that evenly elevates food above the pan, promoting uniform heat distribution and allowing juices to collect below. In contrast, the vertical roaster holds the food upright, increasing air circulation around the entire surface for crispier skin and more even cooking. Vertical roasters are especially favored for poultry, while standard racks are versatile for various meats and vegetables.

Heat Circulation and Airflow: Which Roaster Wins?

Heat circulation and airflow are critical factors in determining the efficiency of roasting racks versus vertical roasters. Vertical roasters generally provide superior airflow, promoting more even heat distribution around the food.

- Standard Roasting Rack - Heat tends to concentrate below the food, potentially causing uneven cooking due to limited airflow on sides and top.

- Vertical Roaster - Designed to maximize airflow around the entire surface area of the food, ensuring more uniform heat circulation.

- Heat Circulation Efficiency - Vertical roasters typically achieve higher heat circulation scores because their orientation allows hot air to flow freely on all sides, improving roasting quality.

Browning and Crispiness: Performance Comparison

Standard roasting racks allow for even heat circulation around the food, promoting consistent browning and a balanced crispiness on all sides. By elevating the food, these racks prevent sogginess caused by sitting in drippings, enhancing the overall texture.

Vertical roasters expose more surface area to direct heat, resulting in deeper browning and a crispier exterior, especially on poultry skin. This design channels fat away from the food, further improving crispiness and reducing grease retention.

Juiciness and Moisture Retention: Side-by-Side Results

Standard roasting racks elevate meat evenly, allowing air circulation that promotes consistent cooking and moisture retention. Vertical roasters position the meat upright, which enhances juiciness by enabling fat to baste the meat naturally during roasting.

In side-by-side comparisons, vertical roasters often yield juicier results due to fat distribution and reduced moisture evaporation. Standard racks, while effective for uniform heat, may allow more juices to drip away, slightly diminishing moisture levels. Choosing between the two depends on desired texture and cooking style preferences.

Capacity and Size Compatibility: Choosing the Right Fit

Standard roasting racks typically offer a larger surface area, making them ideal for roasting multiple or larger cuts of meat simultaneously, accommodating bulky roasts with ease. Vertical roasters optimize space by holding meat upright, which not only saves oven space but also promotes even heat circulation, suitable for smaller kitchens and compact ovens. Selecting the right fit depends on oven size and the volume of food being prepared, with standard racks favoring capacity and vertical roasters excelling in space efficiency.

Ease of Use and Handling: User Experience Insights

| Standard Roasting Rack | Offers straightforward handling with a simple design that accommodates various roasting trays. Its flat surface allows easy placement and removal of poultry, enhancing user convenience during preparation and cleanup. The open structure ensures even air circulation but requires manual rotation for consistent roasting. |

| Vertical Roaster | Designed for effortless placement of whole chickens or roasts by suspending them upright, which simplifies handling and reduces the risk of spillage. This design promotes self-basting and uniform heat distribution, minimizing the need for manual intervention. Users often report easier cleanup due to less contact with roasting pan surfaces. |

Cleaning and Maintenance: Pros and Cons

Standard roasting racks typically accumulate drippings and residues that require thorough scrubbing, while vertical roasters often have removable drip trays that simplify cleanup. Both designs demand regular maintenance to prevent buildup, but vertical roasters generally offer easier access to internal components for cleaning.

- Standard Roasting Rack Cleaning - Often involves manual scrubbing of fixed surfaces and repositioning the rack for thorough washing.

- Vertical Roaster Maintenance - Features detachable parts like drip trays that can be soaked and cleaned separately, reducing overall cleaning time.

- Long-term Upkeep - Vertical roasters may require less frequent deep cleaning due to better grease collection but need consistent attention to avoid clogs.

Choosing between these options depends on balancing ease of cleaning with the intended frequency of roasting and convenience preferences.

Roast Versatility: Which Device Offers More Flexibility?

Standard roasting racks offer consistent heat distribution suitable for a variety of meats and vegetables, making them highly versatile. Vertical roasters, designed primarily for poultry, provide efficient fat drainage and even cooking but have limited application beyond specific items.

- Standard roasting rack - Compatible with multiple types of food due to its flat, open design supporting uniform heat exposure.

- Vertical roaster - Optimized for vertical placement of poultry, enhancing browning and crispiness on all sides.

- Roast versatility - Standard racks accommodate diverse recipes, while vertical roasters are specialized and less flexible in use.

Related Important Terms

Drip Fat Optimization

Standard roasting racks allow fat to drip away from the food through a flat, horizontal surface, promoting even heat circulation and consistent roasting results. Vertical roasters enhance drip fat optimization by positioning food upright, enabling grease to drain efficiently away from the meat, reducing fat retention and resulting in a leaner, crisper finish.

Heat Circulation Vectoring

Standard roasting racks provide even heat distribution through direct contact and horizontal airflow, maximizing surface area exposure for consistent browning. Vertical roasters enhance heat circulation vectoring by allowing hot air to flow uniformly around the entire food surface, reducing moisture retention and promoting faster, more uniform cooking.

Vertical Crispness Effect

Vertical roasters maximize the Vertical Crispness Effect by allowing hot air to circulate evenly around the food, creating a uniformly crisp exterior without the need to flip or turn. Standard roasting racks elevate food but often result in uneven crispness due to limited air flow contact on vertical surfaces.

Rack Marks Aesthetic

Standard roasting racks produce distinctive rack marks that enhance the visual appeal and texture of meats, creating an evenly browned, grid-like pattern prized for presentation. Vertical roasters, by contrast, minimize direct contact with surfaces, resulting in fewer visible rack marks but promoting even heat circulation and juicier, more uniformly cooked food.

Skin Render Performance

Standard roasting racks allow heat to circulate evenly around the meat, promoting uniform skin rendering by elevating it above drippings and preventing sogginess. Vertical roasters enhance skin crispiness by suspending the meat, enabling fat to drip away more efficiently and exposing more surface area to direct heat.

Gravity-Assisted Basting

Standard roasting racks elevate meat above the pan, allowing juices to drip down and preventing sogginess, but offer limited gravity-assisted basting since the juices do not naturally flow back onto the meat. Vertical roasters optimize gravity-assisted basting by positioning the meat upright, enabling natural juices to baste the surface continuously during cooking, enhancing moisture retention and flavor.

Airflow Zone Roasting

Standard roasting racks allow for consistent heat circulation around food, ensuring even cooking with moderate airflow, while vertical roasters maximize airflow by positioning food upright, facilitating faster heat penetration and more uniform roasting in the Airflow Zone. Vertical roasters enhance crispiness and reduce roasting time due to superior air exposure compared to the restricted airflow of traditional racks.

Rack-to-Vertical Caramelization

Standard roasting racks promote even heat distribution with direct surface contact, enhancing uniform caramelization on the bottom of the food, while vertical roasters encourage juices to drip away and circulate heat around the entire surface, resulting in more consistent rack-to-vertical caramelization and a crispy exterior. Vertical roasting optimizes airflow and browning by exposing more surface area, leading to richer, deeper caramelized flavors compared to the flatter, more traditional caramelization seen with standard racks.

Bird Stand Juicing

A vertical roaster allows bird juices to drip directly into the pan, enhancing juiciness and flavor retention by preventing the bird from sitting in its own fat, unlike a standard roasting rack which elevates the bird but may trap juices underneath, reducing optimal juicing. Using a bird stand in vertical roasting promotes even heat circulation and crispier skin while maximizing natural juice collection for basting or gravy preparation.

Standard roasting rack vs vertical roaster for roasting. Infographic

cookingdiff.com

cookingdiff.com