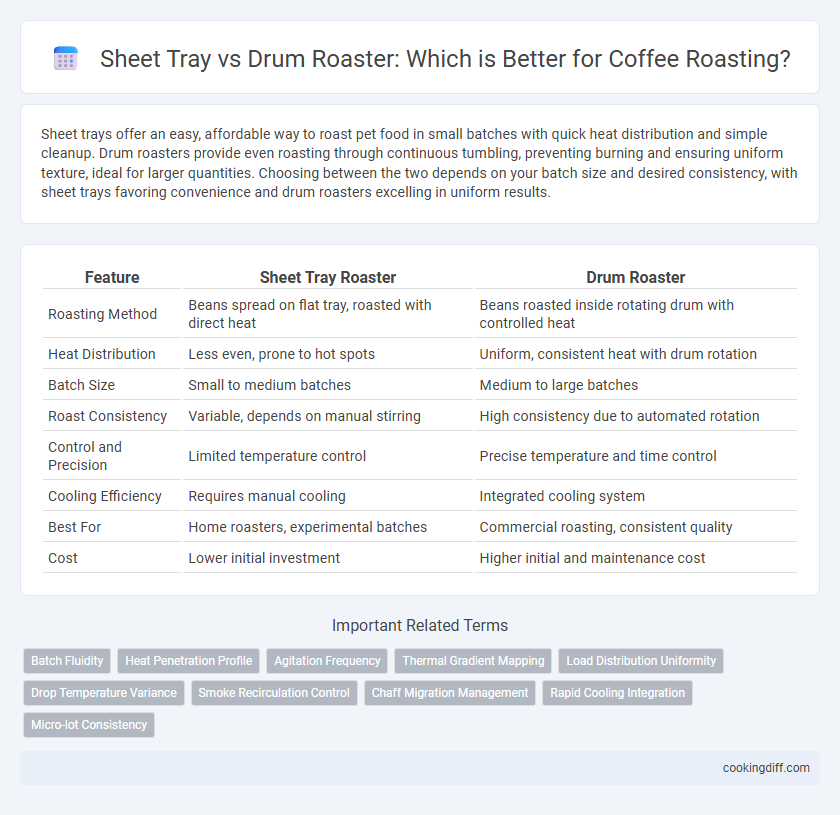

Sheet trays offer an easy, affordable way to roast pet food in small batches with quick heat distribution and simple cleanup. Drum roasters provide even roasting through continuous tumbling, preventing burning and ensuring uniform texture, ideal for larger quantities. Choosing between the two depends on your batch size and desired consistency, with sheet trays favoring convenience and drum roasters excelling in uniform results.

Table of Comparison

| Feature | Sheet Tray Roaster | Drum Roaster |

|---|---|---|

| Roasting Method | Beans spread on flat tray, roasted with direct heat | Beans roasted inside rotating drum with controlled heat |

| Heat Distribution | Less even, prone to hot spots | Uniform, consistent heat with drum rotation |

| Batch Size | Small to medium batches | Medium to large batches |

| Roast Consistency | Variable, depends on manual stirring | High consistency due to automated rotation |

| Control and Precision | Limited temperature control | Precise temperature and time control |

| Cooling Efficiency | Requires manual cooling | Integrated cooling system |

| Best For | Home roasters, experimental batches | Commercial roasting, consistent quality |

| Cost | Lower initial investment | Higher initial and maintenance cost |

Introduction to Roasting Methods: Sheet Tray vs Drum Roaster

Sheet tray roasting offers a simple, cost-effective method where coffee beans are spread evenly on a flat surface and roasted using direct heat. Drum roasters, conversely, utilize a rotating drum to evenly agitate beans, promoting uniform heat distribution and deeper flavor development.

Sheet trays provide greater control over small-batch roasting but may result in uneven roast profiles due to limited airflow and manual stirring. Drum roasters enable consistent temperature regulation and airflow, leading to more precise roasting outcomes ideal for larger batches. Choosing between these methods depends on batch size, desired flavor complexity, and roasting equipment availability.

How Sheet Tray Roasting Works

Sheet tray roasting involves spreading coffee beans in a single layer on a flat metal tray that moves through a hot air oven or roaster. This method ensures even heat distribution by allowing hot air to circulate around the beans, promoting consistent roasting.

The trays rotate or slide through the roasting chamber, facilitating uniform exposure to heat and enabling precise control over roast levels. Sheet tray roasters are ideal for small to medium batches, offering simplicity and ease of use compared to drum roasters.

Understanding Drum Roaster Technology

Drum roaster technology utilizes a rotating drum to evenly roast coffee beans by tumbling them through a heated environment, ensuring consistent heat distribution and uniform development. This method allows precise control over roasting variables such as temperature and time, which is critical for achieving specific flavor profiles. Compared to sheet tray roasting, drum roasters reduce the risk of scorching and promote better airflow, resulting in enhanced bean quality and aroma retention.

Key Differences Between Sheet Tray and Drum Roaster

Sheet tray roasters use a flat surface with hot air circulation, ideal for small batches and uniform roast but with less control over bean movement. Drum roasters rotate beans inside a heated drum, offering more consistent heat exposure and better flavor development for larger batches.

- Heat distribution - Sheet trays rely on convection heat from below, while drum roasters combine convection and conduction heat.

- Batch size - Sheet tray roasters handle smaller quantities suitable for experimental or specialty roasting, unlike drum roasters designed for larger volumes.

- Roast control - Drum roasters provide greater control over agitation and heat, resulting in more consistent and customizable roast profiles.

Flavor Profiles: Comparing Roasting Results

Sheet tray roasting offers even heat distribution resulting in a consistent but milder flavor profile with subtle caramelization. Drum roasting creates complex flavors through constant bean movement and higher, direct heat exposure, producing richer and more intense notes.

- Sheet Tray Flavor Consistency - The flat surface promotes uniform roasting, minimizing burnt or underdeveloped beans.

- Drum Roaster Complexity - Rotation and higher temperatures enhance Maillard reactions, deepening flavor complexity.

- Flavor Development Speed - Drum roasters typically achieve desired roast levels faster, intensifying acidity and body.

Capacity and Efficiency Considerations

Which roasting method offers better capacity and efficiency, sheet tray or drum roaster? Sheet tray roasters typically handle smaller batch sizes but allow for faster, more even heat distribution, ideal for specialty roasting. Drum roasters provide larger capacity with consistent agitation, resulting in uniform roasting for commercial-scale operations.

Temperature Control and Heat Distribution

Sheet tray roasters offer less precise temperature control, often relying on external heat sources that can cause uneven heat distribution across the beans. This can result in inconsistent roast levels, especially with larger batches where hot spots are common.

Drum roasters excel in temperature control with built-in thermostats and rotating drums that ensure uniform heat exposure. The consistent agitation of beans promotes even roasting, reducing the risk of scorching or under-roasting.

Maintenance and Cleaning Requirements

Sheet tray roasters require frequent cleaning due to the flat surface where chaff and oil residues accumulate quickly, demanding manual scrubbing and wiping after each roast. Drum roasters have enclosed rotating drums that typically channel chaff into dedicated collectors, reducing direct contact and easing the cleaning process with less frequent maintenance. Both systems benefit from regular inspection, but drum roasters tend to have longer intervals between deep cleans due to more controlled roasting environments.

Best Foods for Sheet Tray Roasting vs Drum Roasting

Sheet trays excel at roasting vegetables, nuts, and small batches of coffee beans with even heat distribution and easy stirring. Drum roasters are ideal for larger coffee bean batches, providing consistent agitation and uniform roast development.

- Vegetables - Sheet trays allow for even caramelization and crisp edges without burning.

- Nuts - Sheet trays offer gentle heat and easy monitoring to avoid over-roasting delicate nuts.

- Coffee Beans - Drum roasters ensure uniform agitation and temperature control for large-batch coffee roasting.

Choosing the right roasting method depends on food size, batch volume, and desired flavor profile.

Related Important Terms

Batch Fluidity

Sheet tray roasters provide less batch fluidity due to their static design, resulting in uneven heat distribution and inconsistent roast profiles. Drum roasters enhance batch fluidity by continuously tumbling beans, promoting uniform contact with heated surfaces and achieving more consistent roast levels.

Heat Penetration Profile

Sheet tray roasters offer more direct heat exposure, resulting in uneven heat penetration and potential scorching in thinner layers of beans. Drum roasters provide consistent, uniform heat distribution with better heat retention, ensuring even roasting and deeper flavor development throughout the batch.

Agitation Frequency

Sheet tray roasters offer lower agitation frequency, resulting in slower, more even heat distribution ideal for small batches, whereas drum roasters provide high agitation frequency through continuous rotation, promoting uniform roasting for larger quantities. The choice between sheet tray and drum roaster depends on desired roast consistency and batch size requirements.

Thermal Gradient Mapping

Sheet tray roasters offer uneven thermal gradient mapping due to their flat surface, causing irregular heat distribution and potential scorching or under-roasting. Drum roasters provide more consistent thermal gradients by rotating beans within a heated drum, ensuring uniform heat exposure and optimal roast quality.

Load Distribution Uniformity

Sheet tray roasters offer a wider surface area that promotes even load distribution, minimizing hot spots and ensuring uniform bean roasting; drum roasters use tumbling action to constantly move beans, which helps achieve consistent heat exposure and balanced roast profiles. Uniformity in load distribution is enhanced by the tray's flat design for static beans and the drum's rotation for dynamic mixing, each catering to different production scales and roast precision needs.

Drop Temperature Variance

Sheet tray roasters exhibit greater drop temperature variance due to uneven heat distribution, leading to inconsistent roast profiles across coffee batches. Drum roasters maintain more stable drop temperatures, ensuring uniform heat application and consistent bean development during roasting.

Smoke Recirculation Control

Sheet tray roasters struggle with smoke recirculation control due to open-air design, leading to inconsistent smoke exposure and flavor development. Drum roasters feature enclosed chambers with advanced smoke recirculation systems, allowing precise control over smoke levels to enhance coffee aroma and roast uniformity.

Chaff Migration Management

Drum roasters provide better chaff migration management by agitating beans continuously, preventing chaff buildup and ensuring even airflow, while sheet tray roasters often struggle with chaff accumulation due to limited movement and less efficient ventilation. Effective chaff removal in drum roasters reduces the risk of smoke and fire hazards, enhancing roast quality and consistency.

Rapid Cooling Integration

Sheet tray roasters allow for quick batch cooling by easily transferring beans to a cooling tray with high airflow, enabling precise control over roast development. Drum roasters often integrate effective built-in cooling systems that rapidly reduce bean temperature post-roast, enhancing flavor stability and preventing over-roasting.

Sheet Tray vs Drum Roaster for roasting. Infographic

cookingdiff.com

cookingdiff.com