Roasting relies on dry heat circulating evenly around food to achieve a golden-brown exterior, while convection roasting uses a fan to enhance airflow, promoting faster and more uniform browning. Convection roasting intensifies the Maillard reaction, resulting in a crispier crust and more deeply caramelized flavors. The increased air circulation in convection roasting reduces cooking time and helps prevent sogginess compared to traditional roasting methods.

Table of Comparison

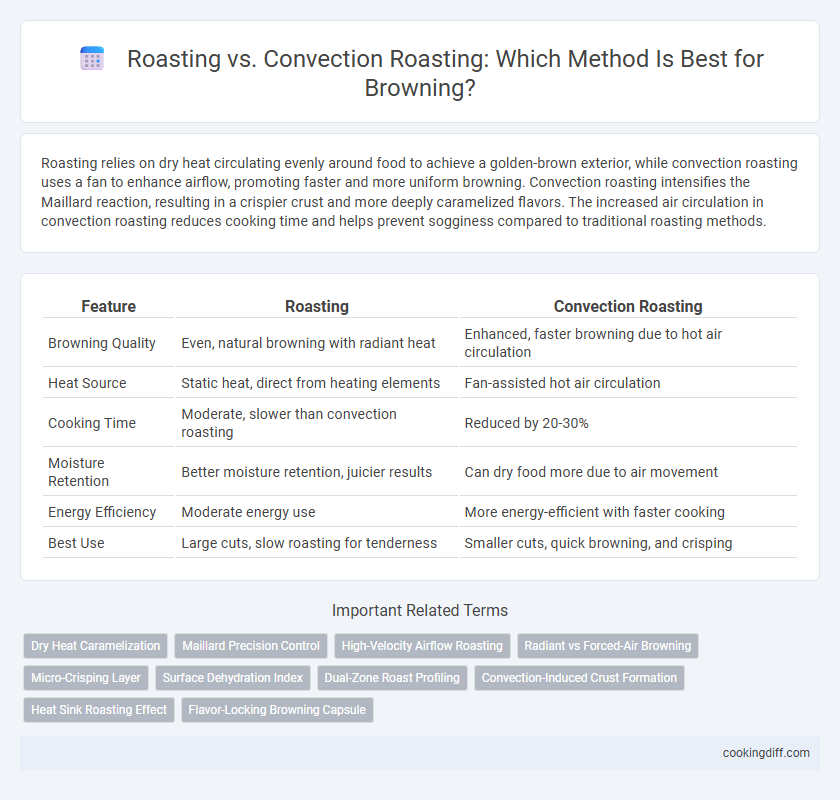

| Feature | Roasting | Convection Roasting |

|---|---|---|

| Browning Quality | Even, natural browning with radiant heat | Enhanced, faster browning due to hot air circulation |

| Heat Source | Static heat, direct from heating elements | Fan-assisted hot air circulation |

| Cooking Time | Moderate, slower than convection roasting | Reduced by 20-30% |

| Moisture Retention | Better moisture retention, juicier results | Can dry food more due to air movement |

| Energy Efficiency | Moderate energy use | More energy-efficient with faster cooking |

| Best Use | Large cuts, slow roasting for tenderness | Smaller cuts, quick browning, and crisping |

Key Differences Between Roasting and Convection Roasting

Roasting uses radiant heat from the oven walls, producing even cooking with gradual browning, while convection roasting employs a fan to circulate hot air, accelerating browning and crisping. Convection roasting typically results in faster cooking times and a more uniform golden crust on meats and vegetables.

- Heat Source - Roasting relies on stationary heat, whereas convection roasting uses fan-forced air for increased heat circulation.

- Cooking Time - Convection roasting reduces cooking time by 25-30% compared to traditional roasting.

- Browning Quality - Convection roasting enhances surface browning and crispiness more effectively than standard roasting.

Select convection roasting for faster, evenly browned results, ideal for meats and root vegetables.

How Roasting Promotes Browning

| Roasting | Roasting uses dry heat in an oven, allowing surface moisture to evaporate and sugars to caramelize, which enhances browning through the Maillard reaction. High, consistent temperatures promote the transformation of amino acids and reducing sugars into flavorful brown compounds. This method creates a robust crust and deep color compared to steaming or boiling. |

| Convection Roasting | Convection roasting increases air circulation with a fan, accelerating moisture evaporation and promoting even browning and crispiness. The enhanced airflow intensifies heat transfer, leading to a faster Maillard reaction and uniform crust formation. This technique also reduces cooking time while maintaining optimal browning and flavor development. |

The Science of Browning in Convection Roasting

Convection roasting enhances the Maillard reaction by circulating hot air evenly, resulting in superior browning and flavor development. The science behind this method lies in consistent heat distribution that accelerates protein and sugar reactions on the food's surface.

- Even Heat Distribution - Convection ovens use fans to circulate hot air, ensuring uniform temperature around the food for consistent browning.

- Accelerated Maillard Reaction - The steady airflow increases surface drying, promoting faster and more intense browning through the Maillard reaction.

- Enhanced Flavor Formation - Better heat circulation intensifies caramelization and flavor compound development, creating richer taste profiles.

Temperature Control: Roasting vs Convection Methods

Roasting typically uses dry, consistent heat from the oven's bottom or top, while convection roasting circulates hot air with a fan for even temperature distribution. Temperature control is more precise in convection roasting, allowing for faster browning and a crispier exterior.

- Roasting Heat Source - Direct heat from oven elements without air circulation results in gradual browning.

- Convection Airflow - Fan-driven hot air promotes uniform temperature and accelerates the Maillard reaction.

- Temperature Precision - Convection roasting maintains steady heat, reducing hot spots and preventing uneven cooking.

Airflow’s Impact on Browning Results

Roasting relies on dry heat circulation around the food, but convection roasting enhances this process by using a fan to increase airflow, promoting even heat distribution. The intensified airflow in convection roasting accelerates moisture evaporation, leading to a crisper, more uniformly browned exterior. This method improves Maillard reaction efficiency, resulting in superior browning and texture compared to traditional roasting.

Cooking Times: Conventional vs Convection Roasting

Conventional roasting typically requires longer cooking times due to heat transfer primarily through radiation and conduction, often needing 20-30% more time compared to convection roasting. The slower heat circulation in conventional ovens can lead to uneven browning, prolonging the overall roasting process.

Convection roasting uses a fan to circulate hot air evenly around the food, significantly reducing cooking times by up to 25%. This enhanced heat distribution promotes faster and more uniform browning, making convection roasting ideal for achieving crisp textures while saving energy.

Effects on Texture and Crust Formation

How do roasting and convection roasting differ in their effects on texture and crust formation? Roasting typically results in a tender interior with a moderately crisp crust due to slower heat penetration. Convection roasting enhances crust formation and creates a more uniformly browned exterior by circulating hot air, which accelerates moisture evaporation and improves texture crispness.

Optimal Foods for Traditional Roasting Browning

Traditional roasting excels at browning foods with high-fat content such as whole chickens, pork shoulders, and root vegetables, as the dry heat promotes Maillard reactions and caramelization. These foods develop rich, crispy exteriors and enhanced flavors through the direct radiant heat of traditional roasting methods.

Convection roasting uses a fan to circulate hot air, resulting in faster and more even cooking but often yielding less intense browning compared to traditional roasting. Optimal foods for convection roasting include lean cuts like turkey breast or fish fillets, where even heat distribution prevents drying while achieving moderate browning.

When to Choose Convection Roasting for Better Browning

Choose convection roasting for better browning when cooking large cuts of meat or multiple items simultaneously, as the fan circulates hot air evenly, promoting consistent caramelization. Convection roasting reduces cooking time and enhances Maillard reactions on the surface, resulting in a crisp, golden crust. This method is ideal for roasting poultry, root vegetables, and dense proteins that benefit from a crispy exterior without overcooking the interior.

Related Important Terms

Dry Heat Caramelization

Roasting uses radiant heat to brown foods through dry heat caramelization, enhancing natural sugars and creating a rich, flavorful crust. Convection roasting circulates hot air evenly, accelerating dry heat caramelization for uniform browning and crisp texture without moisture buildup.

Maillard Precision Control

Roasting with precise Maillard reaction control enhances browning by carefully regulating temperature and airflow, ensuring uniform caramelization and flavor development. Convection roasting accelerates this process through consistent hot air circulation, promoting even browning and reducing the risk of uneven Maillard reactions.

High-Velocity Airflow Roasting

High-velocity airflow roasting enhances browning by circulating hot air rapidly around the food, resulting in a crispier, evenly browned exterior compared to traditional convection roasting that relies on moderate air circulation. This method promotes Maillard reaction efficiency and reduces cooking time by maintaining a consistent high temperature and airflow, optimizing caramelization and surface texture.

Radiant vs Forced-Air Browning

Radiant roasting relies on direct heat radiation to achieve deep browning by caramelizing surface sugars, while convection roasting uses forced-air circulation to evenly distribute heat, promoting uniform browning but often resulting in less intense caramelization. Radiant broilers or infrared heating elements excel at creating crispy, browned exteriors, whereas convection ovens optimize temperature consistency and moisture retention, affecting the texture and color development during roasting.

Micro-Crisping Layer

Roasting develops a Micro-Crisping Layer through direct dry heat that enhances surface browning and flavor complexity, while convection roasting, with its circulating hot air, promotes even cooking but may produce a thinner, less intense crust. The Micro-Crisping Layer formed during traditional roasting results from Maillard reactions accelerated by higher surface temperatures, offering superior texture and caramelization compared to convection roasting.

Surface Dehydration Index

Roasting achieves surface browning primarily through Maillard reactions facilitated by the Surface Dehydration Index, which measures the extent of moisture loss affecting crust formation. Convection roasting enhances heat transfer and moisture evaporation rates, increasing the Surface Dehydration Index to produce a more uniform and crisp crust compared to traditional roasting methods.

Dual-Zone Roast Profiling

Dual-Zone Roast Profiling enhances browning by precisely controlling temperature zones, allowing targeted heat application for optimal Maillard reactions. This method surpasses traditional convection roasting by reducing uneven cooking and improving crust development through tailored thermal gradients.

Convection-Induced Crust Formation

Convection roasting enhances browning by circulating hot air evenly around the food, which accelerates Maillard reactions and promotes a uniformly crisp, golden crust. The increased airflow reduces moisture on the surface, intensifying convection-induced crust formation for superior texture and flavor development compared to conventional roasting.

Heat Sink Roasting Effect

Roasting relies on radiant heat to evenly brown food, while convection roasting accelerates the process by circulating hot air and enhancing heat transfer to the food's surface. The heat sink roasting effect in convection ovens improves browning by rapidly dissipating moisture and promoting Maillard reactions, resulting in a crispier crust and deeper color.

Roasting vs Convection roasting for browning Infographic

cookingdiff.com

cookingdiff.com