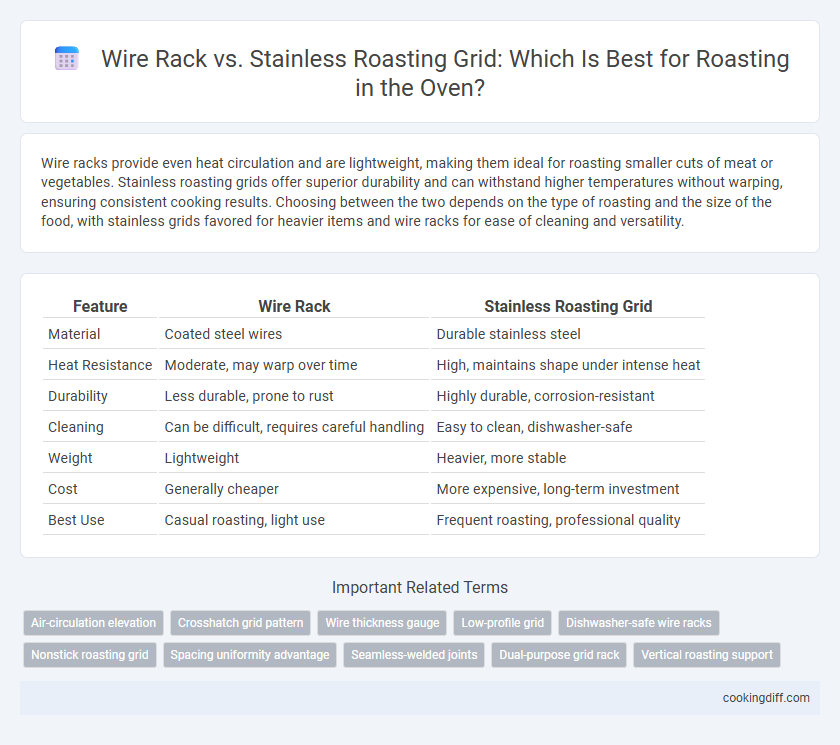

Wire racks provide even heat circulation and are lightweight, making them ideal for roasting smaller cuts of meat or vegetables. Stainless roasting grids offer superior durability and can withstand higher temperatures without warping, ensuring consistent cooking results. Choosing between the two depends on the type of roasting and the size of the food, with stainless grids favored for heavier items and wire racks for ease of cleaning and versatility.

Table of Comparison

| Feature | Wire Rack | Stainless Roasting Grid |

|---|---|---|

| Material | Coated steel wires | Durable stainless steel |

| Heat Resistance | Moderate, may warp over time | High, maintains shape under intense heat |

| Durability | Less durable, prone to rust | Highly durable, corrosion-resistant |

| Cleaning | Can be difficult, requires careful handling | Easy to clean, dishwasher-safe |

| Weight | Lightweight | Heavier, more stable |

| Cost | Generally cheaper | More expensive, long-term investment |

| Best Use | Casual roasting, light use | Frequent roasting, professional quality |

Wire Rack vs Stainless Roasting Grid: Key Differences

| Feature | Wire Rack | Stainless Roasting Grid |

|---|---|---|

| Material | Typically made from coated steel or chrome-plated metal | Constructed from high-grade stainless steel resistant to rust and corrosion |

| Durability | Prone to chipping and rust over long-term use | Long-lasting with strong resistance to wear and environmental damage |

| Heat Distribution | Allows moderate airflow but can heat unevenly under heavy loads | Promotes even heat circulation for consistent roasting results |

| Maintenance | Requires careful drying to prevent rust; may need periodic replacement | Easy to clean and dishwasher safe, maintaining hygiene standards |

| Weight Capacity | Supports lighter roasts, not ideal for very large or heavy items | Engineered to hold larger, heavier cuts of meat securely during roasting |

Material Strength and Durability Comparison

Wire racks made from coated steel offer moderate strength but may warp under high heat, while stainless steel roasting grids are renowned for superior durability and resistance to corrosion. The inherent toughness of stainless steel ensures consistent structural integrity during prolonged roasting sessions.

Stainless steel roasting grids maintain shape and resist rust even after repeated exposure to intense oven temperatures, making them a reliable choice for heavy-duty roasting. Wire racks, although more affordable, often compromise longevity due to thinner gauge materials and less robust coating. For cookware designed to withstand frequent use and provide optimal roasting results, stainless steel grids surpass wire racks in material strength and durability.

Heat Circulation Efficiency in Roasting

Wire racks allow for better airflow around the food, promoting even heat distribution during roasting. Stainless roasting grids, while sturdy and durable, may sometimes restrict air circulation due to their solid design.

- Wire Rack Efficiency - Offers superior heat circulation by elevating food and allowing hot air to flow freely underneath.

- Stainless Roasting Grid Durability - Provides robust support but can limit airflow, potentially affecting roasting uniformity.

- Heat Transfer - Wire racks maximize heat exposure on all sides, enhancing roasting performance compared to some stainless grids.

Choosing a wire rack generally results in more efficient heat circulation and better-roasted food.

Cleaning and Maintenance: Which Is Easier?

Wire racks tend to have simpler designs that allow for easier access during cleaning, reducing the time spent on maintenance. Stainless roasting grids, though durable, often feature thicker bars and complex joints that can trap grease and require more intensive scrubbing.

- Wire racks are lightweight - This makes them easier to handle and clean thoroughly after roasting.

- Stainless roasting grids resist rust - Their material composition helps maintain longevity despite frequent washing.

- Wire racks typically have fewer crevices - Minimizing hidden grease buildup simplifies the cleaning process.

Versatility in the Kitchen: More Than Just Roasting

Wire racks offer exceptional versatility in the kitchen, suitable for roasting, cooling baked goods, and multitasking food preparation. Stainless roasting grids provide durable support for heavier cuts while maintaining consistent heat circulation for even cooking.

- Wire Rack Versatility - Ideal for roasting vegetables and meat, plus perfect as a cooling rack for pastries.

- Stainless Roasting Grid Durability - Strong construction supports larger roasts and withstands high oven temperatures.

- Heat Circulation - Both options promote airflow under the food, enhancing browning and preventing sogginess.

Suitability for Different Foods and Cuts

Which is better suited for different foods and cuts: wire racks or stainless roasting grids? Wire racks offer flexibility and are ideal for smaller cuts and delicate foods that require even airflow without sticking. Stainless roasting grids provide superior durability and firmness, making them perfect for heavier cuts and items that need stable support during roasting.

Impact on Roasting Evenness and Browning

Wire racks provide excellent airflow around the food, promoting even heat distribution and consistent browning during roasting. Their open design helps fat drip away, reducing flare-ups and creating a crispy exterior on meats.

Stainless roasting grids offer durability and heat retention, which can enhance caramelization and searing of the roasted items. However, their solid structure may restrict airflow, potentially causing uneven cooking and less uniform browning.

Space-Saving and Storage Considerations

Wire racks offer a compact and lightweight design, making them ideal for easy storage in small kitchens or tight pantry spaces. Stainless roasting grids, while durable and often heavier, may require more storage room due to their solid construction and bulkier frame. Choosing wire racks can maximize kitchen space efficiency without sacrificing roasting performance, especially when storage is limited.

Cost Analysis: Wire Rack vs Stainless Roasting Grid

Wire racks generally cost less upfront than stainless roasting grids, making them a budget-friendly option for occasional use. Stainless roasting grids, though more expensive, offer greater durability and resistance to rust, which can reduce replacement costs over time. When evaluating long-term investment, stainless grids provide better value due to their longevity and consistent performance during high-heat roasting.

Related Important Terms

Air-circulation elevation

Wire racks offer superior air-circulation elevation compared to stainless roasting grids by creating more open space beneath the food, allowing heat to evenly surround the roast and promote uniform cooking. Stainless roasting grids, while durable and easier to clean, often provide less airflow due to their solid construction, potentially leading to uneven heat distribution and less efficient roasting results.

Crosshatch grid pattern

A wire rack with a crosshatch grid pattern provides even heat circulation and prevents food from sticking, enhancing browning and crisping during roasting. Stainless steel roasting grids offer superior durability and resistance to rust, maintaining their structural integrity while promoting uniform cooking.

Wire thickness gauge

Wire racks with thinner gauge wires typically range from 16 to 18 gauge, allowing heat to circulate evenly while minimizing weight, whereas stainless roasting grids often feature thicker 12 to 14 gauge wires for enhanced durability and weight support. The choice between wire thickness gauges impacts heat distribution efficiency and structural strength, with thinner wires offering better airflow and thicker wires providing superior sturdiness during roasting.

Low-profile grid

A low-profile stainless roasting grid offers superior heat circulation and even cooking compared to a traditional wire rack, minimizing flare-ups and allowing juices to drip away efficiently. Its durable construction resists warping and rust, ensuring long-lasting performance for consistent roast results.

Dishwasher-safe wire racks

Wire racks are preferred for roasting due to their dishwasher-safe convenience, allowing easy cleanup without compromising airflow around the food for even cooking. Stainless steel roasting grids offer durability and rust resistance but often require hand washing, making wire racks a practical choice for hassle-free maintenance during roasting.

Nonstick roasting grid

A nonstick stainless roasting grid offers superior heat distribution and easy cleanup compared to traditional wire racks, preventing food from sticking and ensuring even roasting. Its durable, corrosion-resistant surface enhances cooking efficiency while maintaining structural integrity under high temperatures.

Spacing uniformity advantage

Wire racks provide consistent, evenly spaced bars that ensure uniform heat circulation and optimal air flow around the food, promoting even roasting and browning. Stainless roasting grids offer sturdy construction but often feature wider or uneven spacing, which can lead to less consistent heat distribution and uneven cooking results.

Seamless-welded joints

Wire racks with seamless-welded joints provide superior structural integrity and prevent food particles from getting trapped, enhancing both durability and hygiene compared to traditional stainless roasting grids. Seamless welding also minimizes rust formation and improves heat distribution, making wire racks a more efficient choice for consistent roasting results.

Dual-purpose grid rack

A dual-purpose roasting grid combines the sturdy, heat-resistant qualities of a stainless steel rack with the elevated support of a wire rack, ensuring even heat circulation and optimal browning. This versatile design enhances airflow around the food while preventing sticking, making it ideal for roasting meats, vegetables, and baked goods.

Wire Rack vs Stainless Roasting Grid for Roasting Infographic

cookingdiff.com

cookingdiff.com