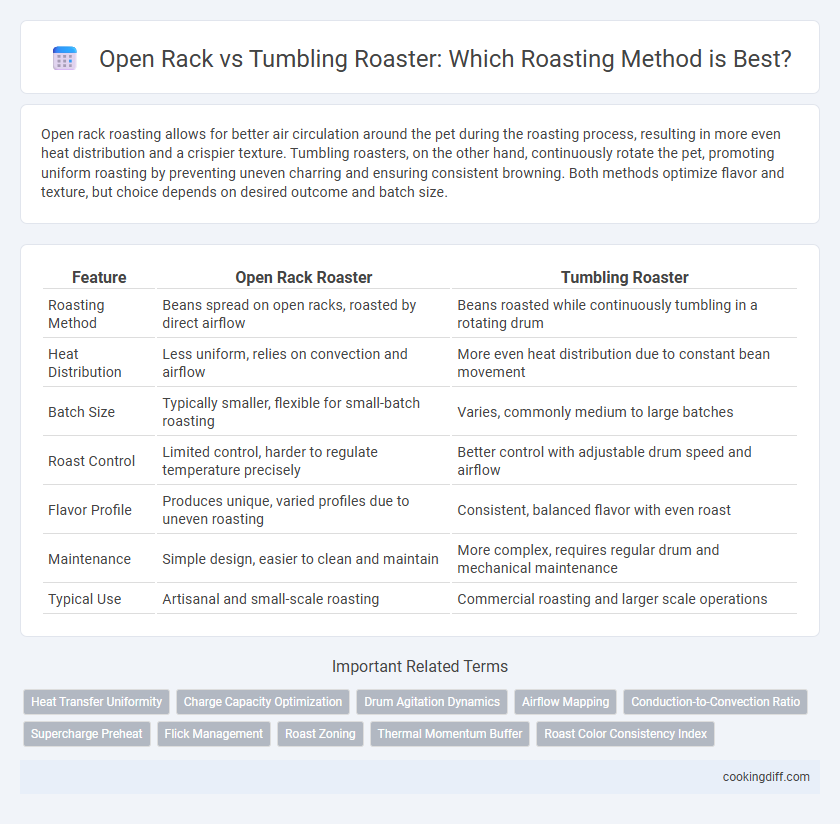

Open rack roasting allows for better air circulation around the pet during the roasting process, resulting in more even heat distribution and a crispier texture. Tumbling roasters, on the other hand, continuously rotate the pet, promoting uniform roasting by preventing uneven charring and ensuring consistent browning. Both methods optimize flavor and texture, but choice depends on desired outcome and batch size.

Table of Comparison

| Feature | Open Rack Roaster | Tumbling Roaster |

|---|---|---|

| Roasting Method | Beans spread on open racks, roasted by direct airflow | Beans roasted while continuously tumbling in a rotating drum |

| Heat Distribution | Less uniform, relies on convection and airflow | More even heat distribution due to constant bean movement |

| Batch Size | Typically smaller, flexible for small-batch roasting | Varies, commonly medium to large batches |

| Roast Control | Limited control, harder to regulate temperature precisely | Better control with adjustable drum speed and airflow |

| Flavor Profile | Produces unique, varied profiles due to uneven roasting | Consistent, balanced flavor with even roast |

| Maintenance | Simple design, easier to clean and maintain | More complex, requires regular drum and mechanical maintenance |

| Typical Use | Artisanal and small-scale roasting | Commercial roasting and larger scale operations |

Introduction to Roasting: Open Rack vs Tumbling Roaster

What are the differences between an open rack and a tumbling roaster in coffee roasting? Open rack roasters allow beans to be roasted in a single layer with direct heat exposure, enhancing surface caramelization and producing a distinct flavor profile. Tumbling roasters continuously agitate beans inside a rotating drum, ensuring uniform heat distribution and consistent roast quality by preventing scorching and uneven roasting.

Overview of Open Rack Roasting Methods

Open rack roasting involves placing food items directly on a wire rack, allowing hot air to circulate freely around the product. This method promotes even cooking and crisping, making it ideal for roasting vegetables, meats, and poultry.

Open rack roasting ensures enhanced heat distribution compared to tumbling roasters, which continuously agitate the product to avoid sticking. It offers better control over browning and texture while preserving the food's natural shape. This technique is favored in commercial kitchens for its simplicity and consistency in producing uniform roast quality.

Tumbling Roaster Technology Explained

Tumbling roaster technology utilizes continuous bean movement inside a rotating drum, ensuring even heat distribution and uniform roasting. Unlike open rack roasters, tumbling roasters provide enhanced control over temperature and airflow, resulting in consistent flavor profiles. This method reduces the risk of scorching and allows for precise development of coffee characteristics through adjustable roasting curves.

Heat Distribution: Comparing Open Rack and Tumbling Roasters

Open rack roasters provide direct heat exposure, allowing beans to roast quickly but with less uniform heat distribution. This method can create hot spots that lead to uneven roasting, especially in larger batches.

Tumbling roasters use a rotating drum to ensure constant movement of beans, promoting even heat distribution throughout the roast. This consistent agitation reduces scorching risks and yields a more uniform roast profile across the batch.

Flavor Development in Different Roasting Techniques

Open rack roasters expose beans to direct, uneven heat, resulting in a complex flavor profile with pronounced acidity and bright notes due to rapid development. Tumbling roasters provide consistent, even heat distribution by continuously rotating the beans, promoting balanced caramelization and deeper, sweeter flavors. The choice between these methods significantly impacts the depth and clarity of flavor development in roasted coffee beans.

Capacity and Efficiency: Which Roaster Handles More?

Open rack roasters typically offer larger batch capacities, making them ideal for high-volume roasting operations that demand continuous output. Tumbling roasters, with smaller capacity drums, provide more uniform heat distribution but handle less volume per batch.

Efficiency in open rack roasters often translates to faster roasting cycles, reducing downtime between batches, which benefits large-scale production schedules. Tumbling roasters excel in quality control and consistency, though this can limit throughput compared to open rack systems.

Maintenance and Cleaning Considerations

Open rack roasters offer straightforward cleaning due to their exposed structure, enabling easy access to all components. Tumbling roasters require more meticulous maintenance as their enclosed design accumulates residues in less accessible areas, demanding regular inspections.

- Open Rack Accessibility - The open framework simplifies debris removal and component checks.

- Tumbling Roaster Complexity - Enclosed chambers trap more oils and chaff, increasing cleaning frequency.

- Maintenance Time - Open racks generally require less downtime for cleaning compared to tumbling models.

Proper maintenance scheduling ensures consistent roast quality and prolongs equipment lifespan in both roaster types.

Cost Comparison: Investment and Operating Expenses

Open racks generally require lower initial investment costs compared to tumbling roasters, making them accessible for small-scale operations. Operating expenses tend to be higher for open racks due to less efficient heat distribution and labor-intensive processes.

- Investment Cost Advantage - Open racks have simpler designs and require less capital expenditure than mechanically complex tumbling roasters.

- Energy Efficiency - Tumbling roasters typically consume less energy per batch because of more controlled and even heat distribution.

- Labor and Maintenance - Open racks incur higher labor costs and frequent maintenance due to manual handling and exposure to environmental factors.

Best Applications: Which Roaster Suits Your Needs?

| Roaster Type | Best Applications | Key Benefits |

|---|---|---|

| Open Rack Roaster | Ideal for small-batch artisan roasts and delicate beans requiring precise heat control. | Allows for easy monitoring and quick cooling, enhancing flavor clarity and consistency. |

| Tumbling Roaster | Suited for medium to large batch sizes and beans needing even heat distribution. | Ensures uniform roasting through continuous bean movement, reducing the risk of scorching. |

Related Important Terms

Heat Transfer Uniformity

Open rack roasters provide less uniform heat transfer due to direct exposure to air currents, leading to uneven roasting profiles. Tumbling roasters enhance heat distribution through constant bean movement and conductive heat transfer from the drum, ensuring more consistent and uniform roasting results.

Charge Capacity Optimization

Open rack roasters typically offer larger charge capacity, enabling bulk roasting which enhances throughput efficiency for commercial operations, while tumbling roasters provide more uniform heat distribution ideal for small to medium batches requiring precise roast profiles. Optimizing charge capacity depends on balancing volume with heat transfer dynamics to maximize roast consistency and operational scalability.

Drum Agitation Dynamics

Open rack roasters provide less consistent drum agitation dynamics compared to tumbling roasters, as the open design allows more variable airflow and uneven bean movement. Tumbling roasters utilize continuous rotation and controlled drum motion to ensure uniform agitation, enhancing even heat distribution and consistent roast profiles.

Airflow Mapping

Open rack roasters offer superior airflow mapping by allowing hot air to circulate freely around the beans, ensuring even heat distribution and consistent roasting profiles. Tumbling roasters rely on continuous bean movement with controlled airflow, creating uniform roast development but may encounter less efficient heat penetration compared to open rack designs.

Conduction-to-Convection Ratio

Open Rack roasters primarily utilize convection heat transfer with a lower conduction-to-convection ratio, promoting even roasting by circulating hot air around the beans. Tumbling roasters offer a higher conduction-to-convection ratio due to direct bean contact with the heated drum surface, enhancing caramelization and development through increased conductive heat transfer.

Supercharge Preheat

Open Rack roasters offer rapid heat transfer with supercharged preheat capabilities, ensuring consistent temperature stabilization crucial for high-quality coffee roasting. Tumbling roasters generate even bean agitation, but their preheat efficiency is generally slower compared to the intense, direct heat exposure in open rack systems.

Flick Management

Open Rack roasters offer superior flick management through adjustable airflow and precise temperature control, ensuring consistent bean movement and even roast development. Tumbling roasters rely on continuous drum rotation for flicking, which can lead to less uniform bean agitation and potential inconsistencies in roast profiles.

Roast Zoning

Open rack roasters provide more variable roast zoning due to uneven heat exposure, often resulting in inconsistent bean development across the batch. Tumbling roasters ensure more uniform roast zoning by continuously agitating beans, promoting even heat distribution and consistent flavor profiles.

Thermal Momentum Buffer

Open Rack roasters provide minimal thermal momentum buffer due to direct exposure to ambient conditions, resulting in rapid temperature fluctuations during the roasting process. Tumbling roasters, with their enclosed rotating drum design, maintain a stable thermal momentum buffer that ensures consistent heat transfer and uniform bean roasting.

Open Rack vs Tumbling Roaster for roasting. Infographic

cookingdiff.com

cookingdiff.com