Roasting pork involves cooking it with dry heat in an oven, resulting in tender, evenly cooked meat with a crispy exterior. Smoke roasting combines indirect heat and smoke, infusing the pork with rich, smoky flavors while maintaining juiciness. Choosing between the two depends on the desired taste profile and cooking time, as traditional roasting is faster, while smoke roasting offers deeper flavor.

Table of Comparison

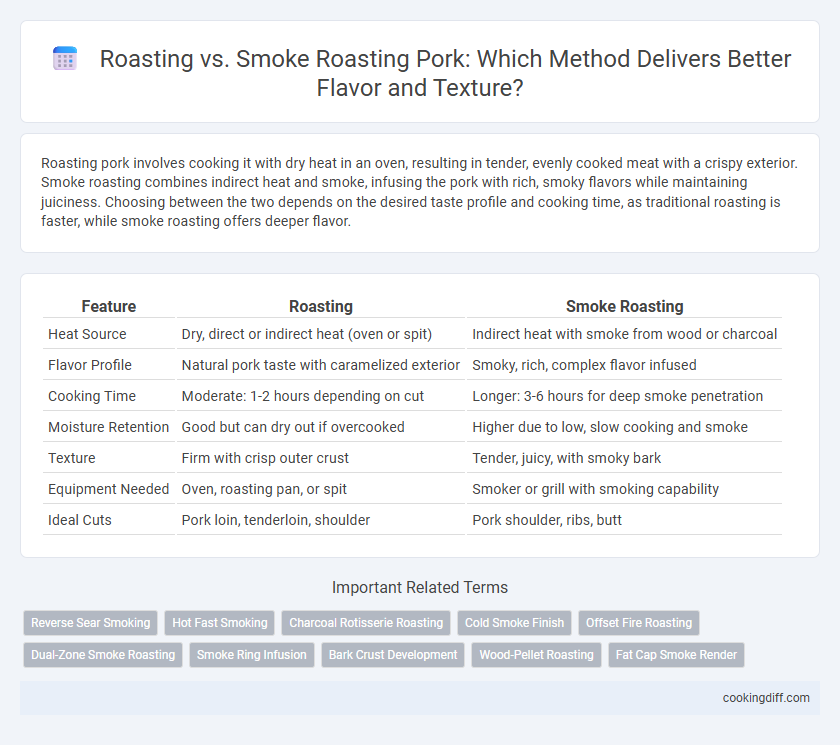

| Feature | Roasting | Smoke Roasting |

|---|---|---|

| Heat Source | Dry, direct or indirect heat (oven or spit) | Indirect heat with smoke from wood or charcoal |

| Flavor Profile | Natural pork taste with caramelized exterior | Smoky, rich, complex flavor infused |

| Cooking Time | Moderate: 1-2 hours depending on cut | Longer: 3-6 hours for deep smoke penetration |

| Moisture Retention | Good but can dry out if overcooked | Higher due to low, slow cooking and smoke |

| Texture | Firm with crisp outer crust | Tender, juicy, with smoky bark |

| Equipment Needed | Oven, roasting pan, or spit | Smoker or grill with smoking capability |

| Ideal Cuts | Pork loin, tenderloin, shoulder | Pork shoulder, ribs, butt |

Understanding Roasting and Smoke Roasting Techniques

Roasting pork involves cooking it in a dry heat environment, typically an oven, allowing for even browning and tender meat through consistent temperature control. Smoke roasting combines roasting with the infusion of smoky flavors by cooking over indirect heat generated by burning wood or charcoal, enhancing the meat's depth of flavor and aroma. Understanding the differences in heat application and flavor development is crucial for selecting the ideal technique to achieve the desired texture and taste in pork dishes.

Key Differences Between Roasting and Smoke Roasting Pork

| Key Differences | Roasting | Smoke Roasting |

|---|---|---|

| Cooking Method | Uses dry heat in an oven or rotisserie at temperatures between 325degF and 375degF to cook pork evenly. | Combines indirect heat and smoke from wood chips at lower temperatures (225degF to 275degF), infusing pork with smoky flavor. |

| Flavor Profile | Produces a juicy interior with a browned, crispy crust focused on caramelization and Maillard reaction. | Imparts a distinct smoky aroma and taste, penetrating the meat slowly for enhanced depth of flavor. |

| Cooking Time | Generally faster, taking 1.5 to 2 hours for whole pork cuts depending on weight and oven settings. | Requires longer durations, often 4 to 6 hours or more, to allow smoke flavor absorption and tenderization. |

Flavor Profiles: Roasted Pork vs Smoke Roasted Pork

Roasted pork delivers a rich, savory flavor with a caramelized crust created by dry heat, emphasizing the natural sweetness of the meat. The Maillard reaction during roasting intensifies the umami notes while preserving tenderness.

Smoke roasting infuses pork with deep, smoky aromas and complex woody flavors, resulting from slow cooking over smoldering hardwood chips. This method enhances the meat with subtle layers of spice and smoke, producing a bold, nuanced taste profile.

Ideal Cuts of Pork for Roasting and Smoke Roasting

Ideal cuts of pork for roasting include the loin, shoulder, and leg, known for their tenderness and ability to retain moisture during dry heat cooking. These cuts benefit from slow, even roasting to develop a flavorful crust while maintaining juicy interiors.

Smoke roasting, also called indirect smoking, is best suited for pork shoulder, butt, and ribs due to their higher fat content and connective tissue, which break down and absorb smoky flavors over extended cooking times. Loin cuts are less ideal for smoke roasting as they can dry out more easily under prolonged heat exposure. Choosing the right cut ensures optimal texture and enhanced flavor profiles in both roasting methods.

Equipment Needed for Roasting and Smoke Roasting

Roasting pork requires an oven or a rotisserie equipped with temperature controls to ensure even cooking and crisp skin. Smoke roasting, alternatively known as barbecuing, demands a smoker or a charcoal grill with a lid to maintain low, consistent heat and infuse the meat with smoky flavors. Essential equipment for smoke roasting also includes wood chips or chunks for producing authentic smoke, which is not needed in traditional roasting.

Cooking Times and Temperature Guidelines

What are the key differences in cooking times and temperature guidelines between roasting and smoke roasting pork? Roasting pork typically requires cooking at a consistent temperature of 325degF to 350degF for about 20 minutes per pound to achieve tender, juicy meat. Smoke roasting, on the other hand, involves lower temperatures ranging from 225degF to 275degF with extended cooking times of 30 to 45 minutes per pound to infuse smoky flavors while maintaining a moist texture.

Preparation Tips for Roasting Pork

Roasting pork requires bringing the meat to room temperature before cooking to ensure even heat distribution and consistent doneness. Season the pork with a dry rub or marinade, allowing flavors to penetrate for at least one hour or overnight for maximum taste enhancement.

Smoke roasting combines roasting with slow smoking, infusing the pork with a rich, smoky flavor while maintaining moisture through controlled low heat. Use wood chips like hickory or applewood and maintain a smoker temperature around 225degF to 250degF for optimal tender results.

Preparation Tips for Smoke Roasting Pork

Smoke roasting pork infuses the meat with rich, smoky flavors while maintaining tenderness through low and slow cooking temperatures. Proper preparation ensures even cooking and enhances the depth of flavor unique to smoke roasting compared to conventional roasting.

- Seasoning and Marinating - Use a dry rub or marinade with bold spices to complement the smoky aroma.

- Wood Selection - Choose hardwoods like apple, hickory, or mesquite for distinct smoke profiles that enhance pork flavor.

- Temperature Control - Maintain a consistent smoker temperature between 225degF and 250degF to ensure the pork cooks thoroughly without drying out.

Allow the pork to rest after smoke roasting to lock in juices before slicing.

Health Considerations: Roasted Pork vs Smoke Roasted Pork

Roasting pork typically involves cooking at dry, high heat which helps retain nutrients while minimizing harmful compound formation. Smoke roasting introduces polycyclic aromatic hydrocarbons (PAHs) and heterocyclic amines (HCAs), potentially increasing health risks due to carcinogenic properties.

- Lower Carcinogen Levels - Traditional roasting generates fewer carcinogenic compounds compared to smoke roasting.

- Retention of Nutrients - Roasting preserves protein quality and essential vitamins better than prolonged smoke exposure.

- Reduced Exposure to Toxins - Smoke roasting can increase exposure to toxins such as PAHs, linked to cancer risk.

Related Important Terms

Reverse Sear Smoking

Reverse sear smoking combines low-temperature smoke roasting with a high-heat sear, enhancing pork's flavor through slow smoke absorption followed by a caramelized crust. This method preserves moisture while infusing rich smoky notes, contrasting traditional roasting that often emphasizes dry heat without smoke complexity.

Hot Fast Smoking

Hot fast smoking combines high temperatures with smoke to infuse pork with rich flavors while maintaining juiciness, whereas traditional roasting relies on dry heat without smoke, resulting in a different texture and taste profile. This method accelerates cooking time and enhances the smoky aroma, making it ideal for tender pork cuts like shoulder or ribs.

Charcoal Rotisserie Roasting

Charcoal rotisserie roasting of pork offers intense, even heat that enhances flavor through Maillard reactions, producing a crispy exterior and juicy interior without the overpowering smoky taste typical of smoke roasting. Unlike smoke roasting, which imparts a distinct smoky aroma and slower cooking process, charcoal rotisserie roasting achieves a balanced caramelization and natural pork essence with consistent rotation over radiant coals.

Cold Smoke Finish

Roasting pork delivers a tender, evenly cooked interior with a caramelized crust by using consistent dry heat, while smoke roasting infuses the meat with rich, smoky flavors from slow combustion of wood chips. Incorporating a cold smoke finish after roasting enhances the pork with a delicate, aromatic smoke layer without raising its internal temperature, preserving juiciness and adding complex flavor profiles.

Offset Fire Roasting

Offset fire roasting delivers even heat and enhanced smokey flavor by positioning the heat source away from the meat, preserving pork's natural juiciness and tenderness better than traditional roasting. Smoke roasting combines indirect heat with controlled smoke circulation, infusing pork with deep, smoky aromas while maintaining a crispy exterior and moist interior.

Dual-Zone Smoke Roasting

Dual-zone smoke roasting for pork combines direct heat with indirect smoking, ensuring tender, juicy meat with a rich smoky flavor profile. This method optimizes temperature control and smoke exposure, enhancing the Maillard reaction without drying out the pork.

Smoke Ring Infusion

Smoke roasting pork creates a distinctive smoke ring infusion due to the reaction of myoglobin with nitrogen dioxide in wood smoke, enhancing both flavor and visual appeal. Traditional roasting lacks this chemical interaction, resulting in a less pronounced smoke ring and a milder smoky flavor profile.

Bark Crust Development

Roasting pork creates a well-formed bark crust through dry heat that caramelizes the surface sugars and renders fat, resulting in a crisp, flavorful exterior. Smoke roasting enhances bark development by infusing the meat with smoky compounds and allowing longer exposure to lower temperatures, which intensifies the crust's depth and complexity.

Wood-Pellet Roasting

Wood-pellet roasting offers precise temperature control and consistent heat distribution, enhancing pork's tenderness and flavor compared to traditional smoke roasting, which imparts deeper smoky notes but less temperature stability. This method combines the convenience of automated fuel feeding with the rich, natural aroma of wood smoke, making it ideal for achieving a balanced crust and juicy interior in pork.

Roasting vs Smoke Roasting for pork. Infographic

cookingdiff.com

cookingdiff.com