A titanium saute pan offers superior durability and excellent heat retention, making it ideal for achieving even cooking and a perfect sear when sauteing. Aluminum pans heat up quickly and provide excellent heat conductivity, but they may warp under high temperatures or react with acidic ingredients. Choosing between the two depends on the need for lightweight responsiveness versus long-lasting strength and scratch resistance during sauteing tasks.

Table of Comparison

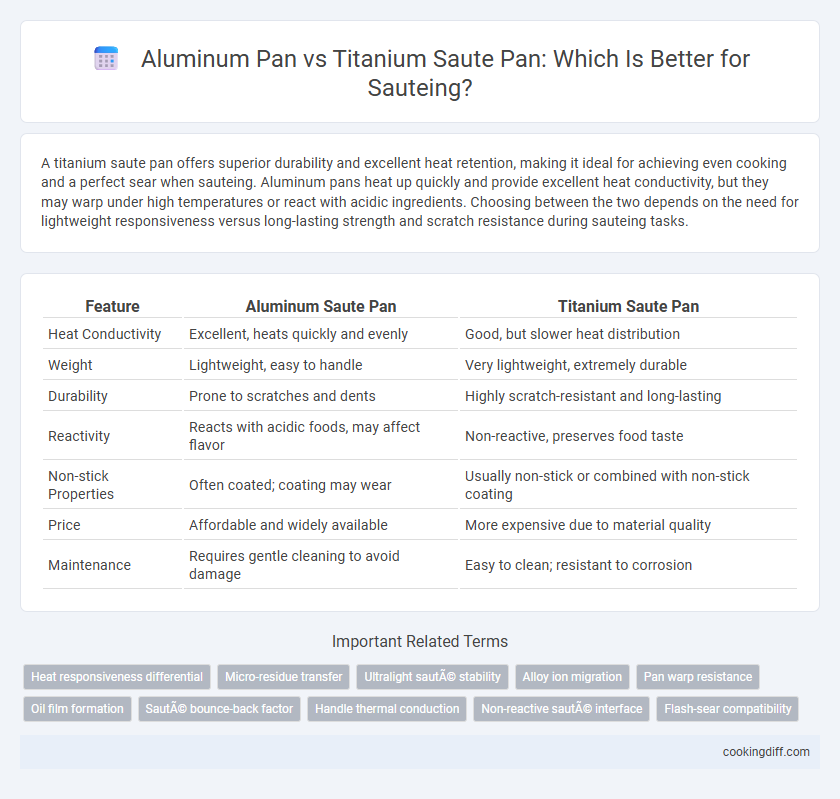

| Feature | Aluminum Saute Pan | Titanium Saute Pan |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Good, but slower heat distribution |

| Weight | Lightweight, easy to handle | Very lightweight, extremely durable |

| Durability | Prone to scratches and dents | Highly scratch-resistant and long-lasting |

| Reactivity | Reacts with acidic foods, may affect flavor | Non-reactive, preserves food taste |

| Non-stick Properties | Often coated; coating may wear | Usually non-stick or combined with non-stick coating |

| Price | Affordable and widely available | More expensive due to material quality |

| Maintenance | Requires gentle cleaning to avoid damage | Easy to clean; resistant to corrosion |

Introduction: Aluminum vs Titanium Sauté Pans

Aluminum saute pans offer excellent heat conductivity, ensuring food cooks evenly and quickly, making them a popular choice in busy kitchens. Their lightweight nature allows for effortless maneuvering during sauteing tasks.

Titanium saute pans are known for their exceptional durability and resistance to warping, maintaining a consistent cooking surface over time. They provide a non-reactive, scratch-resistant option ideal for high-temperature sauteing and frequent use.

Material Properties: Aluminum and Titanium Compared

Aluminum pans offer excellent thermal conductivity, heating quickly and evenly, which is ideal for precise sauteing. However, they are prone to scratching and can react with acidic foods, potentially affecting flavor.

Titanium saute pans are highly durable and resistant to corrosion, providing a non-reactive cooking surface that maintains food integrity. Their heat conductivity is lower than aluminum, but they excel in longevity and withstand high-temperature cooking without warping.

Heat Conductivity: Which Pan Heats Faster?

Aluminum pans excel in heat conductivity, allowing them to heat up faster and distribute heat evenly across the surface. This rapid and uniform heating is ideal for sauteing, ensuring quick cooking and consistent browning.

Titanium saute pans, while durable and non-reactive, have lower heat conductivity compared to aluminum, causing slower heat-up times. They retain heat well once hot but may require more time to reach cooking temperature. For tasks demanding quick temperature changes like sauteing, aluminum pans generally offer superior performance.

Heat Retention: Keeping Steady Temperatures

Aluminum pans excel in rapid heat conduction, allowing for quick temperature adjustments during sauteing. Titanium saute pans, while slower to heat, offer superior heat retention that maintains steady cooking temperatures, reducing hot spots. This consistent heat retention in titanium pans ensures even browning and precise control over sauteed ingredients.

Weight and Handling in Sautéing

| Pan Type | Weight | Handling in Sauteing |

|---|---|---|

| Aluminum Pan | Lightweight, typically 1-2 pounds | Offers excellent maneuverability and quick response for tossing ingredients |

| Titanium Saute Pan | Heavier, usually 3-5 pounds | Provides sturdy handling but may cause fatigue during extended sauteing sessions |

Durability and Longevity of Both Pans

Which pan offers better durability and longevity for sauteing, aluminum or titanium? Titanium saute pans are known for their exceptional strength and resistance to corrosion, making them highly durable over time. Aluminum pans, while excellent heat conductors, are generally less durable and prone to warping or scratching with frequent use.

Reactivity with Ingredients: Flavor & Safety

Aluminum pans are highly reactive with acidic ingredients like tomatoes or lemon juice, which can alter the flavor of sauteed dishes and potentially leach aluminum into food. Titanium saute pans offer a non-reactive cooking surface that preserves the natural taste and safety of ingredients, making them ideal for sauteing a variety of foods. Choosing titanium ensures a more consistent flavor profile and reduces concerns related to metal reactivity and health risks during cooking.

Versatility: Oven-Safe and Compatibility

Aluminum saute pans offer excellent heat conductivity but may have limitations in oven use due to lower heat tolerance and potential warping. Titanium saute pans provide superior versatility with high oven-safe temperatures and compatibility with various cooking surfaces, including induction.

- Oven-Safe Temperature - Aluminum pans typically withstand up to 400degF, while titanium pans can endure temperatures exceeding 600degF.

- Durability - Titanium's robust structure resists warping and corrosion, ensuring long-term performance under intense cooking conditions.

- Cooktop Compatibility - Titanium pans are compatible with gas, electric, and induction cooktops, whereas aluminum pans often require an additional magnetic base for induction.

Titanium saute pans offer enhanced versatility and durability, making them ideal for oven-safe cooking and various stovetop methods.

Cleaning and Maintenance Differences

Aluminum pans are prone to scratching and discoloration if not cleaned gently, requiring hand washing with non-abrasive sponges. Titanium saute pans offer superior durability and resist staining, making them easier to maintain over time.

- Aluminum pans require careful cleaning - Use mild detergents and avoid abrasive materials to prevent surface damage.

- Titanium pans are dishwasher safe - Their robust surface withstands harsh detergents without losing finish.

- Maintenance frequency differs - Aluminum pans may need more regular upkeep to prevent oxidation compared to titanium.

Related Important Terms

Heat responsiveness differential

Aluminum pans offer superior heat responsiveness due to their excellent thermal conductivity, allowing for rapid and even heat distribution crucial for precise sauteing. Titanium saute pans, while exceptionally durable and resistant to scratching, typically have lower thermal conductivity, resulting in slower heat responsiveness and less immediate temperature control during cooking.

Micro-residue transfer

Aluminum pans may release micro-residues during high-heat sauteing, potentially affecting food quality and health, while titanium saute pans exhibit superior resistance to micro-residue transfer due to their non-reactive and durable surface. Titanium's corrosion-resistant properties ensure minimal leaching, making it a safer and more hygienic choice for frequent sauteing at elevated temperatures.

Ultralight sauté stability

Titanium saute pans offer superior ultralight durability and stability compared to aluminum pans, maintaining even heat distribution while resisting warping during high-heat sauteing. Aluminum pans are lightweight and heat quickly but often lack the rigidity and long-term stability required for consistent, precise saute techniques.

Alloy ion migration

Aluminum pans are prone to alloy ion migration during sauteing, which can potentially leach aluminum ions into food, affecting both flavor and health safety. Titanium saute pans exhibit superior resistance to alloy ion migration due to their inert surface, making them a safer and more durable choice for high-heat cooking.

Pan warp resistance

Titanium saute pans offer superior warp resistance compared to aluminum pans, maintaining their flat cooking surface under high heat and frequent temperature changes essential for sauteing. Aluminum pans, while excellent heat conductors, are more prone to warping due to their softness, which can lead to uneven cooking and reduced pan lifespan.

Oil film formation

Aluminum pans offer excellent heat conduction, promoting quick and even oil film formation essential for sauteing, while titanium saute pans, with their durable non-stick surfaces, help maintain a consistent oil layer that reduces sticking and enhances food release. The choice between aluminum and titanium pans impacts the efficiency of oil distribution and retention, directly influencing the sauteing outcome.

Sauté bounce-back factor

Titanium saute pans offer superior saute bounce-back due to their rigid structure, ensuring ingredients lift easily without sticking, while aluminum pans tend to flex more, reducing rebound efficiency. This enhanced bounce-back in titanium pans promotes better food release and consistent cooking outcomes.

Handle thermal conduction

Aluminum pans exhibit excellent thermal conductivity, causing handles to heat quickly and potentially require protective gloves, whereas titanium saute pans feature handles with lower thermal conduction, remaining cooler and safer to touch during cooking. Choosing a titanium saute pan enhances safety and comfort by minimizing heat transfer to the handle.

Non-reactive sauté interface

Aluminum saute pans typically feature a non-reactive anodized coating that prevents food from reacting with the metal, ensuring pure flavors during cooking. Titanium saute pans inherently provide a non-reactive surface, offering excellent durability and resistance to corrosion without the need for additional coatings.

Aluminum pan vs titanium sauté pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com