A nonstick pan offers easy food release and simple cleanup, making it ideal for delicate sauteed ingredients like vegetables and seafood. Carbon steel woks excel at high-heat cooking, providing superior heat retention and quick, even searing for meats and stir-fry dishes. Choosing between the two depends on your preference for temperature control and the types of ingredients you frequently saute.

Table of Comparison

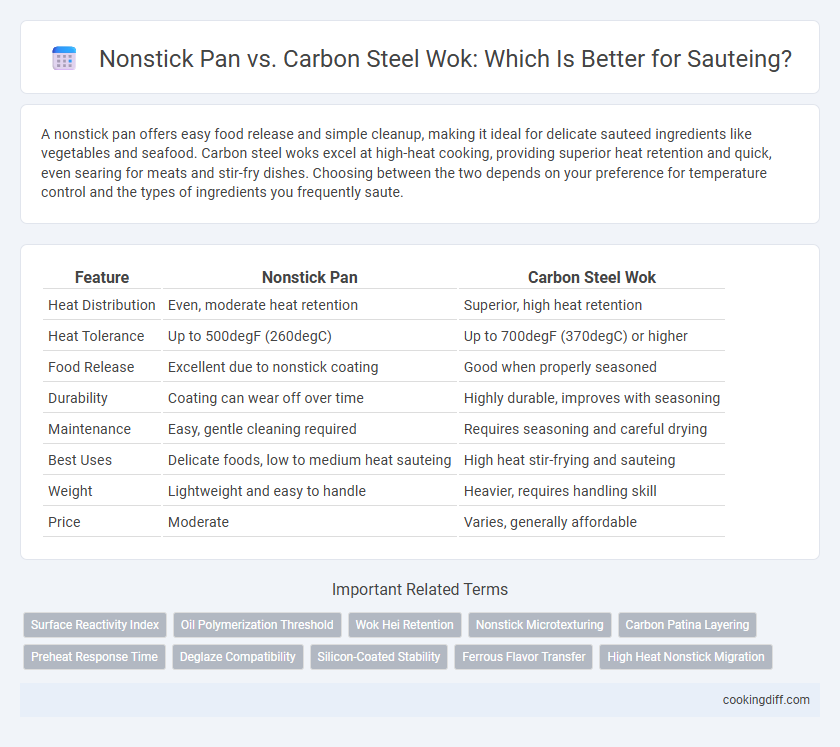

| Feature | Nonstick Pan | Carbon Steel Wok |

|---|---|---|

| Heat Distribution | Even, moderate heat retention | Superior, high heat retention |

| Heat Tolerance | Up to 500degF (260degC) | Up to 700degF (370degC) or higher |

| Food Release | Excellent due to nonstick coating | Good when properly seasoned |

| Durability | Coating can wear off over time | Highly durable, improves with seasoning |

| Maintenance | Easy, gentle cleaning required | Requires seasoning and careful drying |

| Best Uses | Delicate foods, low to medium heat sauteing | High heat stir-frying and sauteing |

| Weight | Lightweight and easy to handle | Heavier, requires handling skill |

| Price | Moderate | Varies, generally affordable |

Overview: Nonstick Pan vs Carbon Steel Wok for Sautéing

Nonstick pans provide an easy-release surface ideal for sauteing delicate foods like eggs and vegetables, requiring less oil and offering effortless cleanup. Their uniform heat distribution is suitable for lower to medium heat cooking but may deteriorate under high temperatures.

Carbon steel woks excel at high-heat sauteing with superior heat retention and quick temperature changes, perfect for stir-frying and developing complex flavors. They require seasoning to maintain a natural nonstick surface and prevent rust, offering durability and versatility beyond nonstick pans.

Heat Distribution and Control

Nonstick pans provide even heat distribution, ensuring food cooks uniformly without sticking, making them ideal for low to medium heat sauteing. Carbon steel woks excel in heat control, rapidly adjusting temperature for high-heat searing and quick stir-fry cooking.

- Nonstick pans offer consistent heat spread - Their coating prevents hotspots, enabling gentle and even cooking.

- Carbon steel woks have superior heat retention - They maintain high temperatures for prolonged periods, perfect for intense sauteing.

- Carbon steel woks respond quickly to temperature changes - This allows precise heat control during fast cooking techniques.

Choosing between these cookware types depends on the required heat intensity and desired cooking style for sauteing.

Nonstick Properties: Pros and Cons

Nonstick pans offer excellent food release and require less oil, making them ideal for low-fat sauteing. Their smooth surface prevents food from sticking, which simplifies cleaning and reduces cooking time.

Despite these advantages, nonstick pans have limitations such as lower heat tolerance and potential scratching from metal utensils. They are often less durable than carbon steel woks, which can develop a natural seasoning that improves over time. Nonstick coatings may degrade with frequent high-heat use, affecting performance and safety.

Seasoning and Maintenance Requirements

Nonstick pans require minimal seasoning and offer easy maintenance, making them ideal for sauteing delicate foods without sticking issues. Their coating, however, can degrade over time with high heat or abrasive cleaning, necessitating gentle care to extend lifespan.

Carbon steel woks need regular seasoning to build a natural nonstick layer that enhances flavor and prevents rust. Maintenance involves careful drying and occasional re-oiling, which demands more effort but results in a durable, long-lasting cooking surface perfect for high-heat sauteing.

Cooking Speed and Temperature Tolerance

Which pan offers better cooking speed and temperature tolerance for sauteing, a nonstick pan or a carbon steel wok? A carbon steel wok can withstand higher temperatures, allowing for faster searing and efficient heat distribution. Nonstick pans provide even cooking but typically have lower temperature limits, which can slow down cooking speed and reduce browning quality.

Versatility in the Kitchen

Nonstick pans excel in versatility for sauteing by providing a smooth, easy-release surface that requires minimal oil, enhancing healthy cooking options. Carbon steel woks offer superior heat retention and rapid temperature changes, making them ideal for high-heat sauteing and stir-frying with wok hei flavor. Both tools support diverse culinary techniques, but the choice depends on cooking style and desired flavor outcomes.

Flavor Development and Browning

Carbon steel woks excel in flavor development and browning due to their high heat retention and responsiveness, which promotes the Maillard reaction. Nonstick pans offer ease of use but typically lack the intense searing capability needed for deep caramelization.

- Heat Retention - Carbon steel woks maintain high temperatures, facilitating faster and more even browning essential for complex flavor profiles.

- Surface Reactivity - The natural seasoning of carbon steel enhances flavor development by creating a subtle nonstick surface that intensifies browning without chemical coatings.

- Temperature Limits - Nonstick pans generally cannot withstand high heat without damage, limiting their effectiveness in achieving the deep caramelization characteristic of sauteed dishes.

Health Considerations for Each Option

Nonstick pans reduce the need for excessive oil, which can contribute to healthier cooking by lowering fat intake. Carbon steel woks require seasoning to maintain a natural nonstick surface, potentially releasing trace amounts of iron that may benefit health.

- Nonstick coatings - Often made from PTFE, they are safe at normal cooking temperatures but can release harmful fumes if overheated.

- Seasoned carbon steel - Natural seasoning creates a non-toxic barrier that improves with use and minimizes reactive food contact.

- Iron leaching - Carbon steel woks may add dietary iron, which can be advantageous for those with iron deficiencies.

Durability and Longevity

Carbon steel woks offer superior durability and can last a lifetime with proper seasoning and care, resisting warping and high heat damage better than nonstick pans. Nonstick pans, while convenient for low-fat cooking, tend to degrade over time as their coatings wear off, typically lasting 1 to 3 years depending on usage. For high-temperature sauteing and long-term investment, carbon steel woks provide unmatched longevity and performance.

Related Important Terms

Surface Reactivity Index

Nonstick pans exhibit a low Surface Reactivity Index, minimizing chemical interactions and ensuring delicate sauteed foods retain their natural flavors without metallic aftertaste. Carbon steel woks have a higher Surface Reactivity Index, promoting Maillard reactions and developing complex flavors but requiring seasoning to prevent food from sticking and reacting undesirably.

Oil Polymerization Threshold

Nonstick pans have a lower oil polymerization threshold, typically around 350degF (175degC), making them ideal for sauteing delicate foods at moderate temperatures without oil breakdown. Carbon steel woks withstand higher temperatures up to 500degF (260degC), allowing efficient sauteing with rapid oil polymerization that enhances flavor and seasoning development.

Wok Hei Retention

Carbon steel woks excel in retaining Wok Hei due to their high heat tolerance and rapid temperature recovery, essential for authentic stir-fry flavor and aroma. Nonstick pans, while easier to clean, lack the intense heat retention needed for developing Wok Hei, resulting in less flavorful sauteed dishes.

Nonstick Microtexturing

Nonstick pans with microtextured surfaces offer superior food release and minimal oil requirement, making them ideal for delicate sauteing tasks like vegetables and fish. In contrast, carbon steel woks provide high heat retention and excellent browning but typically require seasoning and more oil, which can impact the texture and flavor during sauteing.

Carbon Patina Layering

Carbon steel woks develop a natural patina layer through seasoning that enhances non-stick properties and improves flavor retention over time. This patina forms a durable, oil-polymerized surface that resists food sticking better than nonstick pan coatings during high-heat sauteing.

Preheat Response Time

Carbon steel woks have a faster preheat response time due to their excellent heat conductivity and thin construction, allowing for quick temperature adjustments essential in sauteing. Nonstick pans generally take longer to preheat and may not retain heat as efficiently, which can affect the consistent searing and browning of ingredients during sauteing.

Deglaze Compatibility

Nonstick pans offer excellent deglaze compatibility due to their smooth surface, making it easier to loosen browned bits without scraping or damaging the coating. Carbon steel woks can achieve a more intense sear and flavor during sauteing, but their surface requires careful seasoning and handling when deglazing to prevent rust and maintain optimal performance.

Silicon-Coated Stability

Silicon-coated nonstick pans provide superior heat stability and prevent food from sticking during sauteing, ensuring even cooking and easy cleanup. Carbon steel woks offer excellent heat retention and durability but require seasoning to maintain a natural nonstick surface, which can be less stable compared to silicon-coated coatings.

Ferrous Flavor Transfer

Carbon steel woks may impart a subtle ferrous flavor to sauteed foods due to their reactive iron content, enhancing the dish's complexity, especially in acidic or high-moisture ingredients. In contrast, nonstick pans offer a neutral cooking surface that prevents flavor transfer, preserving the pure taste of sauteed ingredients without metallic influence.

Nonstick pan vs Carbon steel wok for sautéing. Infographic

cookingdiff.com

cookingdiff.com