Sauteing typically involves using stainless steel or non-stick pans, which offer quick and even heat distribution essential for browning and searing. Stone pan sauteing utilizes a stone-coated surface that provides superior non-stick properties and retains heat longer, allowing for gentle and consistent cooking. Choosing between these pans depends on the desired cooking technique: traditional sauteing favors high heat and rapid cooking, while stone pan sauteing excels in preventing sticking and evenly cooking delicate ingredients.

Table of Comparison

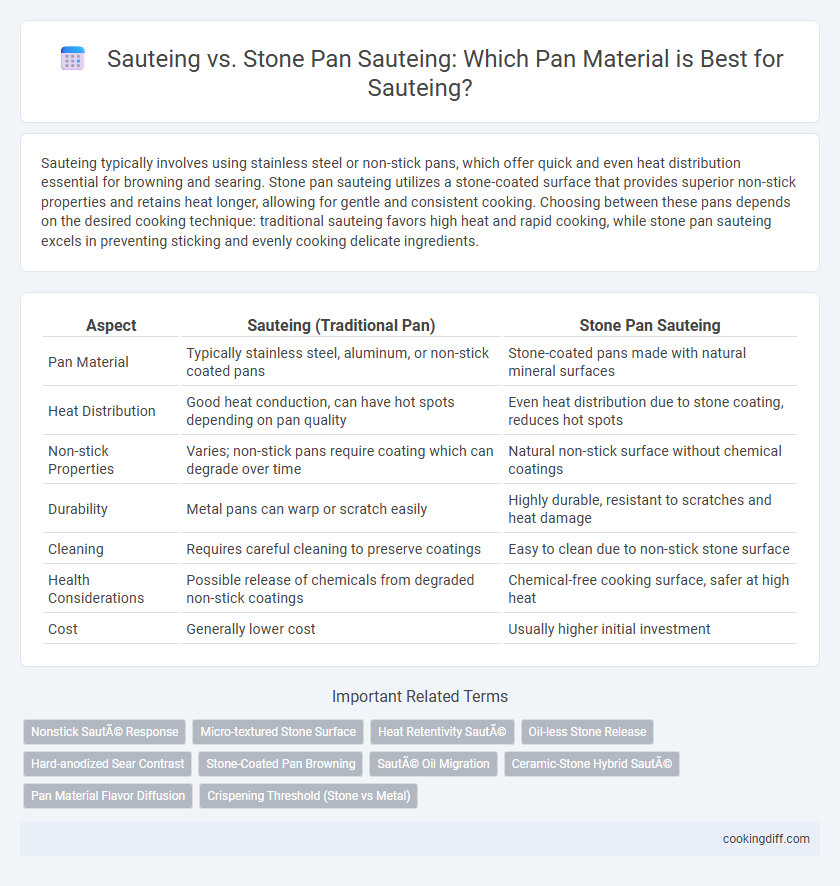

| Aspect | Sauteing (Traditional Pan) | Stone Pan Sauteing |

|---|---|---|

| Pan Material | Typically stainless steel, aluminum, or non-stick coated pans | Stone-coated pans made with natural mineral surfaces |

| Heat Distribution | Good heat conduction, can have hot spots depending on pan quality | Even heat distribution due to stone coating, reduces hot spots |

| Non-stick Properties | Varies; non-stick pans require coating which can degrade over time | Natural non-stick surface without chemical coatings |

| Durability | Metal pans can warp or scratch easily | Highly durable, resistant to scratches and heat damage |

| Cleaning | Requires careful cleaning to preserve coatings | Easy to clean due to non-stick stone surface |

| Health Considerations | Possible release of chemicals from degraded non-stick coatings | Chemical-free cooking surface, safer at high heat |

| Cost | Generally lower cost | Usually higher initial investment |

Understanding Sautéing: Basics and Techniques

Sauteing requires a pan material that heats quickly and distributes heat evenly to ensure food cooks uniformly without burning. Stone pan sauteing offers superior heat retention and non-stick properties, enhancing flavor development while reducing oil use.

- Traditional Sauteing - Uses stainless steel or aluminum pans for rapid temperature control and a responsive cooking surface.

- Stone Pan Sauteing - Utilizes stone-coated pans that provide excellent heat retention and a naturally non-stick finish.

- Technique Impact - Pan material influences the browning process and moisture retention critical to perfect sauteing results.

The Role of Pan Material in Sautéing

The choice of pan material significantly influences heat distribution and retention during sauteing. Traditional saute pans made of stainless steel or aluminum provide quick, even heating essential for proper searing and browning.

Stone pans, often coated with a non-stick layer, offer superior heat retention and a natural non-stick surface that reduces the need for excess oil. Their heavier weight and unique surface texture can affect how ingredients caramelize and release from the pan.

What Makes Stone Pans Unique for Sautéing?

Stone pans offer superior heat retention and even heat distribution compared to traditional metal pans, making them ideal for sauteing. Their naturally non-stick surfaces reduce the need for excessive oil, enhancing the cooking process and flavor development.

Unlike standard saute pans, stone pans resist scratching and maintain durability under high heat, ensuring consistent performance. The mineral composition of stone pans creates a unique cooking environment that seals in moisture and enhances the texture of sauteed foods.

Heat Distribution: Traditional vs Stone Pan Sautéing

| Pan Material | Heat Distribution |

|---|---|

| Traditional Sauteing (Stainless Steel, Aluminum) | Provides rapid and even heat conduction with quick temperature response, but hotspots can occur depending on material quality and thickness. |

| Stone Pan Sauteing | Offers slower, more uniform heat distribution with excellent heat retention, reducing temperature fluctuations and promoting consistent cooking results. |

Nonstick Properties: Metal vs Stone Pans

Nonstick properties vary significantly between metal and stone pans, with stone pans typically offering a naturally nonstick surface due to their mineral composition. Metal pans often require synthetic coatings like Teflon to achieve nonstick capabilities, which can degrade over time and with high heat. Stone pans provide durable, chemical-free nonstick performance, making them ideal for sauteing delicate ingredients without excessive oil.

Flavor Development: Impact of Pan Material

How does the choice between traditional pans and stone pans affect flavor development when sauteing? Traditional pans, often made of stainless steel or cast iron, provide even heat distribution that enhances browning and caramelization, essential for deep flavor development. Stone pans retain heat longer and distribute it more evenly, resulting in a gentler sauteing process that preserves the natural flavors of ingredients without burning.

Ease of Cleaning: Stone vs Conventional Pans

Stone pans typically feature a non-stick surface that resists food adhesion, making them easier to clean compared to conventional pans. Traditional saute pans often require more scrubbing and soaking due to their metal surfaces that can retain food residues.

- Stone pans resist sticking - The natural textured coating minimizes food buildup, reducing cleanup effort.

- Conventional pans may retain residues - Metal surfaces can trap oils and burnt bits, complicating washing.

- Durability affects cleaning - Stone coatings withstand abrasive cleaning better than some conventional pan coatings.

Choosing stone pans can streamline post-cooking maintenance due to their superior ease of cleaning.

Health Considerations: Coatings and Materials

Sauteing in traditional non-stick pans often involves coatings like PTFE, which can release harmful fumes at high temperatures, posing health risks. Stone pans, made from natural mineral-infused materials, provide a chemical-free cooking surface that reduces the risk of toxic exposure during sauteing.

- Non-stick coatings - Polytetrafluoroethylene (PTFE) coatings can degrade and emit fumes when overheated.

- Stone pan materials - Constructed from natural mineral composites, offering a safer alternative without synthetic chemicals.

- Health safety - Stone pans maintain non-toxic cooking even under high heat compared to some traditional non-stick surfaces.

Durability and Longevity: Pan Material Comparison

Stainless steel pans used in traditional sauteing offer exceptional durability and resistance to warping, making them a long-lasting choice for high-heat cooking. In contrast, stone pans provide a non-stick surface but may suffer from chipping or surface degradation over time.

Stone pan sauteing involves cookware with a mineral-infused surface that enhances non-stick properties yet requires careful maintenance to avoid wear. The inherent hardness of stone pans offers good heat retention but can compromise longevity if exposed to sudden temperature changes. Stainless steel pans maintain structural integrity with frequent use and cleaning, supporting consistent performance over years.

Related Important Terms

Nonstick Sauté Response

Nonstick pans provide superior food release and easier cleanup compared to stone pans when sauteing, enhancing cooking efficiency and reducing oil use. Stone pan sauteing offers robust heat retention but may require more oil and careful temperature control to prevent sticking.

Micro-textured Stone Surface

Sauteing on a micro-textured stone surface enhances heat distribution and retention, providing even cooking and superior browning compared to traditional smooth pans. The stone material's natural non-stick properties reduce oil usage and prevent food from sticking, resulting in healthier meals and easier cleanup.

Heat Retentivity Sauté

Sauteing in traditional stainless steel pans offers rapid heat responsiveness but lower heat retentivity, causing temperature fluctuations during cooking. Stone pan sauteing provides superior heat retention due to the dense, heat-absorbing material, enabling consistent temperature control and even cooking results.

Oil-less Stone Release

Sauteing with traditional pans typically requires oil to prevent sticking, while stone pan sauteing offers superior oil-less stone release due to its naturally non-stick mineral coating. This feature allows cooking with minimal or no oil, enhancing both health benefits and ease of food release during the sauteing process.

Hard-anodized Sear Contrast

Hard-anodized pans provide superior heat retention and even searing during sauteing, resulting in a pronounced sear contrast that enhances flavor and texture. Stone pan sauteing, while offering natural non-stick properties, often lacks the intense, consistent heat distribution of hard-anodized surfaces, making them less effective for achieving the distinct caramelization critical in professional sauteing.

Stone-Coated Pan Browning

Stone-coated pans excel in stone pan sauteing by providing superior heat retention and even distribution, allowing for better browning and caramelization of ingredients. This enhanced surface minimizes sticking and promotes flavorful, evenly browned dishes compared to traditional sauteing in standard pans.

Sauté Oil Migration

Sauteing with traditional pans often causes oil migration into the food, affecting texture and flavor, whereas stone pan sauteing minimizes oil absorption due to its non-porous surface, leading to healthier and more evenly cooked dishes. Stone pans retain heat better and reduce the amount of oil needed, promoting less greasy results without compromising sauteing efficiency.

Ceramic-Stone Hybrid Sauté

Ceramic-stone hybrid saute pans combine the heat retention and non-stick benefits of stone with the even heat distribution of ceramic, offering superior control for sauteing delicate ingredients. These pans minimize oil usage and resist scratching, making them ideal for high-temperature cooking that preserves flavor and texture without compromising durability.

Pan Material Flavor Diffusion

Sauteing with traditional stainless steel or cast iron pans allows for superior heat retention and even flavor diffusion, enhancing the caramelization and depth of sauteed ingredients. Stone pan sauteing offers a non-stick surface that minimizes oil usage but may slightly hinder flavor layering due to its less reactive, insulating material compared to metal pans.

Sautéing vs Stone Pan Sautéing for pan material. Infographic

cookingdiff.com

cookingdiff.com