Sauteing involves cooking food quickly in a hot pan with a small amount of oil, promoting caramelization and flavor development through direct contact heat. Infrared sauteing uses infrared radiation to deliver intense, even heat, accelerating the browning process without overheating the food's surface. This method enhances rapid browning while maintaining moisture and texture more effectively than traditional sauteing.

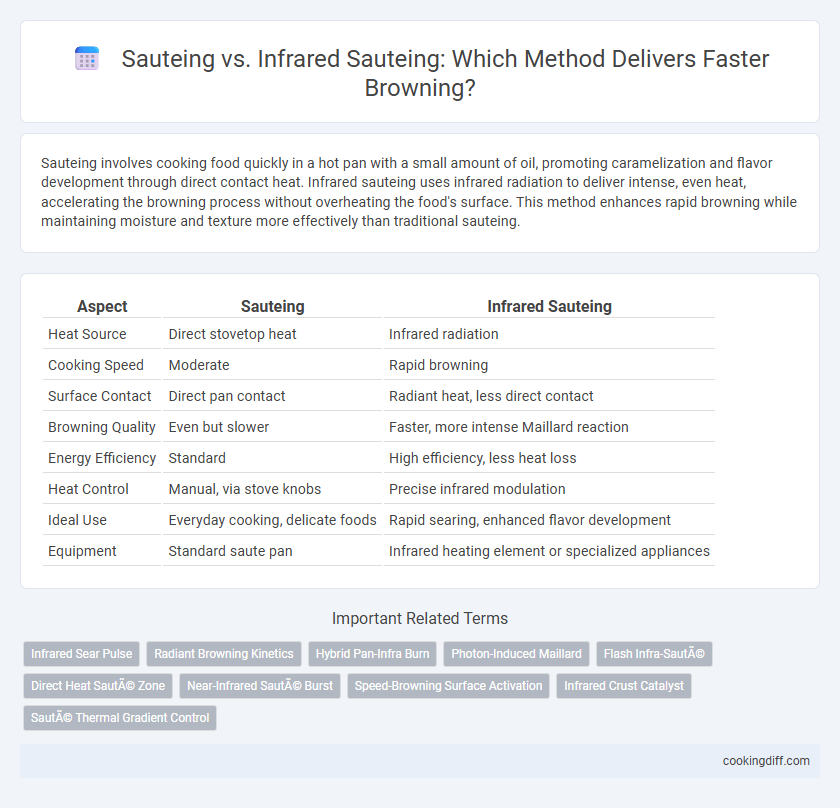

Table of Comparison

| Aspect | Sauteing | Infrared Sauteing |

|---|---|---|

| Heat Source | Direct stovetop heat | Infrared radiation |

| Cooking Speed | Moderate | Rapid browning |

| Surface Contact | Direct pan contact | Radiant heat, less direct contact |

| Browning Quality | Even but slower | Faster, more intense Maillard reaction |

| Energy Efficiency | Standard | High efficiency, less heat loss |

| Heat Control | Manual, via stove knobs | Precise infrared modulation |

| Ideal Use | Everyday cooking, delicate foods | Rapid searing, enhanced flavor development |

| Equipment | Standard saute pan | Infrared heating element or specialized appliances |

Introduction to Sautéing and Infrared Sautéing

Sauteing is a cooking technique that uses a hot pan and a small amount of oil to rapidly cook food, promoting quick browning and caramelization. Infrared sauteing employs infrared radiation to deliver intense, even heat that accelerates browning while preserving moisture and flavor. Both methods enhance Maillard reaction efficiency, but infrared sauteing offers superior heat control and faster cooking times for optimal texture.

How Traditional Sautéing Works for Browning

Traditional sauteing achieves browning through direct contact with a hot pan, causing the Maillard reaction that develops flavor and color. The technique relies on quick, even heat transfer, often using oil to prevent sticking and enhance heat distribution.

- Contact Heat Transfer - Heat is conducted directly from the pan surface to the food, triggering browning.

- Maillard Reaction - Amino acids and sugars react under heat, producing the characteristic browned crust.

- Oil Usage - Oil helps to evenly distribute heat and prevents food from adhering to the pan surface.

This method requires constant motion and temperature control to avoid burning and ensure uniform browning.

The Science Behind Infrared Sautéing

Infrared sauteing uses electromagnetic waves to directly heat food surfaces, enabling faster and more uniform browning compared to traditional sauteing methods that rely on conduction from a hot pan. This process enhances the Maillard reaction by achieving higher surface temperatures quickly without overheating the oil or food interior.

- Direct Surface Heating - Infrared radiation targets the food surface, accelerating heat absorption and promoting rapid browning.

- Efficient Energy Transfer - Energy is transferred through radiation rather than conduction, minimizing heat loss and allowing precise temperature control.

- Enhanced Maillard Reaction - The higher surface temperature created by infrared waves intensifies the chemical reaction responsible for browning and flavor development.

Heat Distribution: Traditional vs Infrared Methods

How does heat distribution differ between traditional sauteing and infrared sauteing for rapid browning? Traditional sauteing relies on direct contact heat from a pan, which may lead to uneven browning due to hot spots. Infrared sauteing delivers more uniform heat distribution by emitting infrared radiation, enabling faster and more consistent browning across the food surface.

Speed of Browning: A Direct Comparison

Sauteing achieves browning through direct contact with a hot pan, typically taking several minutes to develop a golden crust. Infrared sauteing uses concentrated infrared heat to rapidly elevate surface temperatures, reducing browning time significantly.

Infrared sauteing can brown foods up to 50% faster than traditional methods, improving cooking efficiency without sacrificing flavor. The accelerated Maillard reaction in infrared cooking enhances crust formation and color intensity within seconds.

Flavor Development in Sautéing Techniques

Sauteing creates rich, complex flavors through direct contact with hot oil, promoting Maillard reactions for enhanced browning. Infrared sauteing offers rapid browning by delivering even, intense heat, preserving moisture and intensifying flavor development.

- Traditional Sauteing - Uses direct pan heat and oil to develop deep, caramelized flavors through slow Maillard reactions.

- Infrared Sauteing - Provides faster browning with uniform heat distribution, boosting flavor intensity without overcooking.

- Flavor Development - Both methods enhance taste but infrared sauteing excels in speed and moisture retention for juicier results.

Texture and Moisture Retention in Rapid Browning

Sauteing uses direct contact with a hot pan to rapidly brown food, creating a slightly crisp texture while maintaining moderate moisture levels. Infrared sauteing generates intense, evenly distributed heat that enhances rapid browning and results in a superior sear with better moisture retention.

Infrared sauteing minimizes surface moisture loss due to its precise heat control, preserving juiciness and tenderness in proteins and vegetables. This method produces a consistently caramelized crust without overcooking the interior, unlike traditional sauteing that may cause uneven texture. Enhanced texture and moisture retention make infrared sauteing ideal for achieving restaurant-quality rapid browning results.

Equipment Needed: Standard Pans vs Infrared Devices

| Equipment Needed | Standard Sauteing | Infrared Sauteing |

|---|---|---|

| Heat Source | Gas or electric stovetop burners with direct flame or coil | Infrared burners emitting high-intensity light waves for rapid heat transfer |

| Pans | Traditional stainless steel, cast iron, or non-stick saute pans with flat bottoms | Specialized infrared-compatible pans designed to maximize radiant heat absorption |

| Temperature Control | Manual control via burner knobs providing gradual heat adjustments | Electricized control units allowing precise, rapid temperature changes |

| Surface Contact | Direct contact between pan surface and stovetop burner | Radiant heat transferred without direct contact, enabling faster browning |

| Set-up Complexity | Simple setup with standard kitchen equipment | Requires installation of infrared heating units and compatible cookware |

Energy Efficiency: Which Method Wins?

Sauteing traditionally uses direct heat from a stovetop, often leading to uneven energy distribution and longer cooking times. Infrared sauteing employs radiant heat that rapidly penetrates food, resulting in faster browning with less energy consumption.

Infrared technology converts nearly 90% of energy into usable heat, outperforming conventional sauteing methods that typically reach around 60% efficiency. This makes infrared sauteing the superior choice for energy-conscious cooking while achieving optimal browning results.

Related Important Terms

Infrared Sear Pulse

Infrared Sear Pulse technology enhances sauteing by delivering intense, concentrated heat that achieves rapid browning and caramelization far quicker than traditional methods. This precise heat control minimizes moisture loss and ensures a crisp exterior while maintaining tender, juicy interiors.

Radiant Browning Kinetics

Sauteing relies on conductive heat transfer from a hot pan surface to rapidly brown food through the Maillard reaction, while infrared sauteing uses radiant heat to accelerate surface browning by directly transferring energy to the food's exterior molecules. Infrared radiant browning kinetics enhance caramelization speed and uniformity, reducing cooking time and improving texture compared to traditional sauteing methods.

Hybrid Pan-Infra Burn

Hybrid Pan-Infra Burn technology combines traditional sauteing with infrared heat to achieve rapid browning by evenly distributing high temperatures across the pan surface. This method enhances Maillard reactions more efficiently than conventional sauteing, resulting in faster caramelization and improved flavor depth.

Photon-Induced Maillard

Photon-induced Maillard reactions during infrared sauteing enable significantly faster and more uniform browning compared to traditional sauteing methods by directly exciting molecular vibrations at the food surface, accelerating complex chemical transformations. Infrared sauteing enhances heat transfer efficiency and promotes rapid caramelization, resulting in improved flavor development and texture within a shorter cooking time.

Flash Infra-Sauté

Flash Infra-Saute harnesses infrared radiation for rapid browning, delivering intense, even heat that sears food faster than traditional sauteing methods. This technique reduces cooking time while enhancing flavor development and creating a superior Maillard reaction on the food surface.

Direct Heat Sauté Zone

Infrared sauteing provides a higher intensity of direct heat in the saute zone, enabling rapid browning with enhanced Maillard reaction efficiency compared to traditional sauteing. The concentrated thermal energy accelerates surface caramelization, resulting in improved texture and flavor development within a shorter cooking time.

Near-Infrared Sauté Burst

Near-Infrared Saute Burst technology accelerates rapid browning by delivering intense, focused heat that penetrates the food surface evenly, enhancing Maillard reactions compared to traditional sauteing methods. This innovation reduces cooking time while preserving texture and flavor, making it a superior choice for chefs seeking efficiency and optimal caramelization.

Speed-Browning Surface Activation

Infrared sauteing achieves rapid browning by using high-intensity infrared radiation to uniformly activate the Maillard reaction on the surface, significantly faster than conventional sauteing's direct heat conduction. This speed-browning surface activation minimizes moisture loss and enhances flavor development, making infrared sauteing an efficient method for achieving optimal browning in less time.

Infrared Crust Catalyst

Infrared Sauteing utilizes the Infrared Crust Catalyst technology to achieve rapid browning by generating intense, uniform heat that promotes superior Maillard reactions compared to traditional sauteing methods. This results in a perfectly caramelized crust with enhanced flavor and texture in a shorter cooking time.

Sautéing vs Infrared Sautéing for rapid browning. Infographic

cookingdiff.com

cookingdiff.com