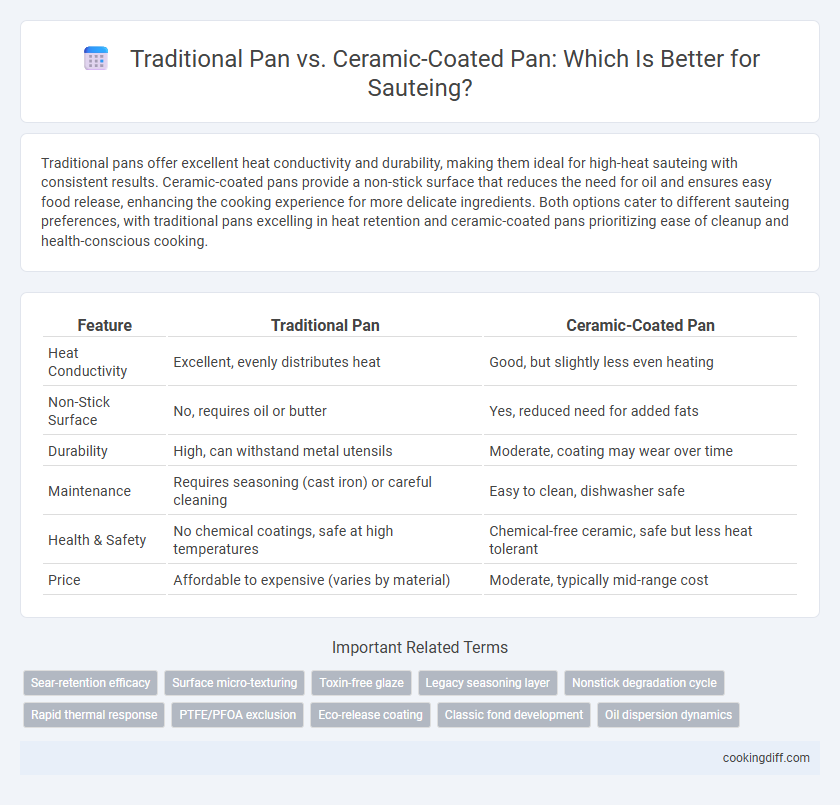

Traditional pans offer excellent heat conductivity and durability, making them ideal for high-heat sauteing with consistent results. Ceramic-coated pans provide a non-stick surface that reduces the need for oil and ensures easy food release, enhancing the cooking experience for more delicate ingredients. Both options cater to different sauteing preferences, with traditional pans excelling in heat retention and ceramic-coated pans prioritizing ease of cleanup and health-conscious cooking.

Table of Comparison

| Feature | Traditional Pan | Ceramic-Coated Pan |

|---|---|---|

| Heat Conductivity | Excellent, evenly distributes heat | Good, but slightly less even heating |

| Non-Stick Surface | No, requires oil or butter | Yes, reduced need for added fats |

| Durability | High, can withstand metal utensils | Moderate, coating may wear over time |

| Maintenance | Requires seasoning (cast iron) or careful cleaning | Easy to clean, dishwasher safe |

| Health & Safety | No chemical coatings, safe at high temperatures | Chemical-free ceramic, safe but less heat tolerant |

| Price | Affordable to expensive (varies by material) | Moderate, typically mid-range cost |

Introduction to Sautéing: Technique and Tools

| Traditional pans such as stainless steel or cast iron offer excellent heat retention and high-temperature tolerance, making them ideal for achieving the perfect sear in sauteing. |

| Ceramic-coated pans provide non-stick properties with less required oil and easier cleanup, but may have lower heat tolerance and shorter lifespan compared to traditional pans. |

| Choosing the right saute pan depends on the cooking technique, desired browning effect, and maintenance preferences, with traditional pans favored for flavor development and ceramic-coated pans preferred for convenience. |

What is a Traditional Pan? Materials and Properties

A traditional pan for sauteing is typically made from stainless steel, cast iron, or aluminum, known for excellent heat retention and even cooking. Stainless steel pans offer durability and non-reactive surfaces, while cast iron provides superior heat distribution and long-lasting seasoning properties. Aluminum pans are lightweight with rapid heat conduction but often require non-stick coatings to prevent food from sticking.

Understanding Ceramic-Coated Pans: Composition and Benefits

Ceramic-coated pans feature a non-toxic, inorganic ceramic layer that provides excellent non-stick properties and resists high temperatures ideal for sauteing. Unlike traditional pans, ceramic coatings offer superior scratch resistance and require less oil, enhancing flavor retention and promoting healthier cooking. The even heat distribution of ceramic-coated pans ensures consistent sauteing results and prevents food from sticking or burning compared to conventional metal surfaces.

Heat Distribution: Traditional vs Ceramic-Coated Pans

Traditional pans, often made of stainless steel or cast iron, provide excellent heat retention and even heat distribution, making them ideal for precise sauteing. Ceramic-coated pans heat up quickly but may have less consistent heat distribution, affecting cooking performance for delicate dishes.

Ceramic coatings offer a non-stick surface that requires less oil, enhancing the sauteing process by reducing food sticking and burning. However, traditional pans generally maintain heat better under high temperatures, offering superior control for searing and caramelizing ingredients.

Nonstick Performance: Which Pan Delivers Better Results?

Traditional pans often feature seasoned surfaces that improve nonstick performance over time, making them suitable for high-heat sauteing without sticking. Ceramic-coated pans provide immediate nonstick capabilities but can degrade faster under intense heat, potentially affecting sauteing results.

- Durability - Traditional pans resist high temperatures and maintain seasoning layers through repeated use.

- Maintenance - Ceramic-coated pans require gentle care to preserve their nonstick surface and prevent chipping.

- Heat Tolerance - Traditional pans perform better at consistent high heat, essential for optimal sauteing without food sticking.

Cooking with Oil and Butter: Absorption and Release

Traditional pans, often made of stainless steel or cast iron, tend to absorb less oil and butter, allowing fats to remain on the surface for better browning and flavor release during sauteing. These pans develop a natural seasoning that enhances non-stick properties over time, reducing the amount of added fats needed.

Ceramic-coated pans, while excellent for even heat distribution, absorb more oil and butter into their porous surfaces, which can limit the immediate release of flavors and lead to higher fat consumption. The smooth, non-stick ceramic layer often requires less butter or oil but may cause quicker fat degradation at high temperatures.

Ease of Cleaning: Maintenance and Longevity

Traditional pans often require rigorous cleaning to prevent staining and maintain seasoning, which can be time-consuming but enhances durability through proper care. Ceramic-coated pans offer non-stick surfaces that simplify cleaning, reducing residue buildup and minimizing the need for scrubbing.

Maintenance of traditional pans involves regular seasoning to preserve their surface and prevent rust, extending their longevity when properly cared for. Ceramic-coated pans resist scratches and corrosion, contributing to easier upkeep and prolonging their usability. Choosing between these depends on the balance of maintenance effort and long-term durability desired in sauteing cookware.

Safety and Health Considerations: Material Impact

Traditional pans, often made from stainless steel or cast iron, are durable but may leach metals like nickel or iron during cooking, impacting health if used improperly. Ceramic-coated pans offer a non-toxic, chemically inert surface that reduces the risk of harmful substance release, promoting safer sauteing.

- Metal leaching in traditional pans - Some metals can seep into food at high temperatures, especially if the pan is scratched or damaged.

- Ceramic coating safety - Ceramic coatings are free from PTFE and PFOA, chemicals linked to health concerns in non-stick surfaces.

- Heat resistance and degradation - Ceramic pans resist high heat without degrading, minimizing toxic byproduct formation during sauteing.

Choosing ceramic-coated pans for sauteing enhances safety by reducing exposure to potentially harmful materials from cookware.

Price Comparison: Cost Versus Value in Sautéing

Traditional pans are generally more affordable but may require seasoning and maintenance to prevent sticking, affecting long-term value for sauteing. Ceramic-coated pans come at a higher initial cost but offer non-stick convenience and easier cleanup, potentially offsetting their price over time.

- Lower upfront cost - Traditional pans typically cost less, making them more accessible for budget-conscious cooks.

- Long-term durability concerns - Traditional pans often need regular upkeep, which can increase total ownership costs.

- Ease of use boosts value - Ceramic-coated pans reduce cooking and cleaning time, adding convenience that may justify their higher price.

Related Important Terms

Sear-retention efficacy

Traditional pans, often made of stainless steel or cast iron, offer superior sear-retention efficacy due to their ability to maintain high and consistent heat, crucial for achieving a perfect caramelized crust during sauteing. Ceramic-coated pans, while non-stick and easier to clean, generally have lower heat retention and distribution, which can result in less effective searing and reduced flavor development.

Surface micro-texturing

Traditional pans often feature a smoother surface micro-texture that promotes even browning and flavor development during sauteing, while ceramic-coated pans provide a slightly rougher micro-texture that enhances non-stick properties and requires less oil. The difference in surface micro-texturing influences heat distribution and food release, affecting the overall sauteing experience and ease of cleaning.

Toxin-free glaze

Ceramic-coated pans provide a toxin-free glaze that ensures safe sauteing without the risk of harmful chemical leaching, unlike some traditional pans with non-stick coatings containing PTFE or PFOA. This makes ceramic-coated cookware a healthier choice for high-heat cooking, maintaining food flavor integrity and minimizing potential exposure to toxic fumes.

Legacy seasoning layer

Traditional pans develop a legacy seasoning layer that enhances flavor and improves natural non-stick properties over time, making them ideal for sauteing. Ceramic-coated pans lack this buildup, offering a smooth surface that resists sticking initially but may not replicate the depth of flavor achieved with a well-seasoned traditional pan.

Nonstick degradation cycle

Traditional pans with nonstick coatings often experience a degradation cycle that begins with surface scratches leading to flaking and loss of nonstick properties, reducing their effectiveness for sauteing. Ceramic-coated pans offer a more durable nonstick surface resistant to high heat and abrasive cooking utensils, maintaining performance longer without toxic chemical breakdowns.

Rapid thermal response

Traditional pans offer rapid thermal response due to their metal construction, allowing precise control over heat adjustments during sauteing. Ceramic-coated pans provide even heat distribution but generally have slower thermal response times, which may affect quick temperature changes needed for delicate sauteing techniques.

PTFE/PFOA exclusion

Ceramic-coated pans for sauteing offer a non-stick surface free from PTFE and PFOA, reducing potential health risks associated with traditional pans coated with these chemicals. Unlike traditional pans, ceramic coatings provide a safer alternative while maintaining effective heat distribution for optimal sauteing performance.

Eco-release coating

Traditional pans typically feature stainless steel or cast iron surfaces that require more oil for sauteing and can lead to food sticking, whereas ceramic-coated pans with Eco-release coatings offer superior nonstick performance with minimal oil, ensuring healthier cooking and easier cleanup. Ceramic Eco-release coatings enhance heat distribution and durability while being free from harmful chemicals, making them an environmentally friendly choice for efficient sauteing.

Classic fond development

Traditional stainless steel pans excel at classic fond development due to their high heat tolerance and ability to create a natural, browned residue essential for deglazing and rich sauces. Ceramic-coated pans, while nonstick and easier to clean, often lack the surface texture and heat retention needed to form a robust fond, making them less ideal for authentic sauteing techniques.

Traditional pan vs ceramic-coated pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com