Sauteing uses direct contact with a hot pan and a small amount of oil to quickly transfer heat, creating a crisp texture and caramelized flavors. Steam-frying combines sauteing with steam from added moisture or vegetables, which slows heat transfer and results in a tender, evenly cooked dish with less browning. Understanding the differences in heat transfer between sauteing and steam-frying helps optimize texture and flavor in cooking.

Table of Comparison

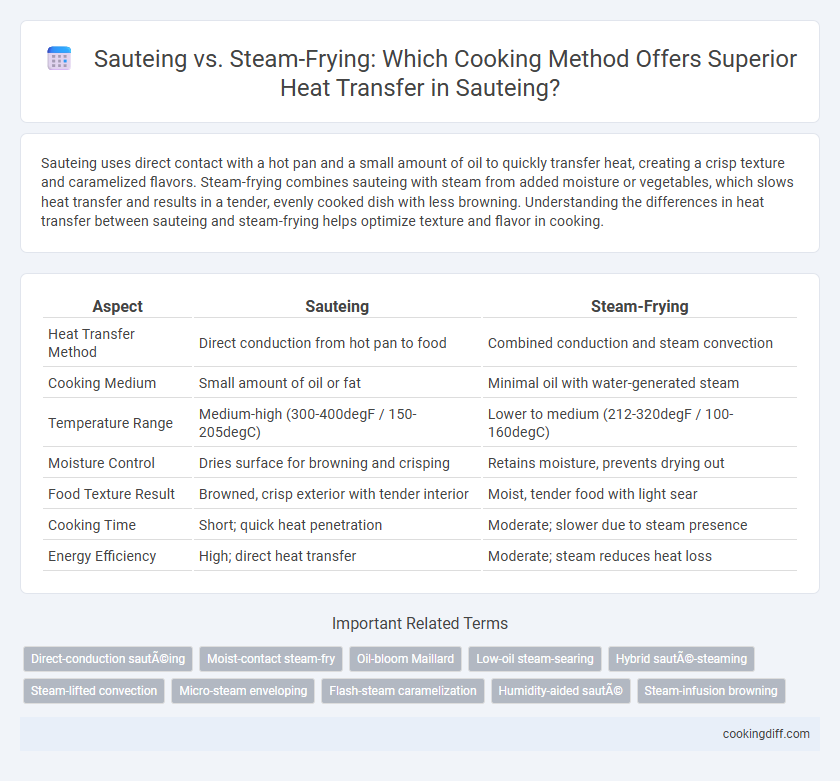

| Aspect | Sauteing | Steam-Frying |

|---|---|---|

| Heat Transfer Method | Direct conduction from hot pan to food | Combined conduction and steam convection |

| Cooking Medium | Small amount of oil or fat | Minimal oil with water-generated steam |

| Temperature Range | Medium-high (300-400degF / 150-205degC) | Lower to medium (212-320degF / 100-160degC) |

| Moisture Control | Dries surface for browning and crisping | Retains moisture, prevents drying out |

| Food Texture Result | Browned, crisp exterior with tender interior | Moist, tender food with light sear |

| Cooking Time | Short; quick heat penetration | Moderate; slower due to steam presence |

| Energy Efficiency | High; direct heat transfer | Moderate; steam reduces heat loss |

Understanding Sautéing: Direct Heat and Quick Cooking

Sauteing utilizes direct heat transfer through a hot pan and a small amount of oil, allowing for rapid cooking and browning of ingredients. The intense heat promotes caramelization and Maillard reactions, enhancing flavor development in a short time.

Steam-frying combines sauteing with steaming by adding a small amount of liquid, creating a moist cooking environment that slows heat transfer compared to pure direct contact. This method retains more moisture but reduces the intensity of browning, resulting in tender textures with less crispness.

What is Steam-Frying? A Blend of Heat and Moisture

Steam-frying is a cooking technique that combines the direct heat of frying with the moisture of steaming, creating a unique heat transfer method that enhances flavor and texture. This hybrid approach allows food to cook evenly while retaining moisture, unlike traditional sauteing which relies solely on dry heat conduction.

- Moisture Integration - Steam-frying introduces steam during cooking, preventing food from drying out and preserving juiciness.

- Heat Transfer Efficiency - The presence of steam improves heat conduction, resulting in faster and more uniform cooking.

- Texture Enhancement - Combining steam with frying produces a tender interior with a crisp exterior, balancing softness and crunch.

Comparing Heat Transfer Methods: Sautéing vs Steam-Frying

Sauteing uses direct contact with hot oil to transfer heat efficiently, creating a Maillard reaction that enhances flavor and texture. Steam-frying combines steam and high heat, allowing faster heat penetration while retaining moisture and reducing oil absorption. The choice between methods depends on desired crispiness and moisture retention, with sauteing offering more browning and steam-frying preserving juiciness.

Moisture Content: Impact on Food Texture and Flavor

How does moisture content influence the texture and flavor during sauteing compared to steam-frying? Sauteing uses high, direct heat that quickly evaporates surface moisture, resulting in a crisp, caramelized exterior and intensified flavor profile. Steam-frying retains more moisture by combining oil and steam heat, producing a tender texture with a milder, juicier taste.

Efficiency of Heat Transfer: Which Method Cooks Faster?

Sauteing transfers heat rapidly through direct contact with a hot pan, allowing foods to cook quickly and develop a crisp texture. Steam-frying combines sauteing with steam, which can slow heat transfer due to the insulating effect of vapor, though it retains moisture better.

In terms of efficiency, sauteing generally cooks faster because the dry heat directly sears the food, while steam-frying takes longer as the steam tempers the cooking process. For speed and browning, sauteing remains the superior method in most culinary applications.

Oil vs Water: Mediums of Heat Conduction

Sauteing relies on oil as a heat transfer medium, which reaches higher temperatures than water without boiling, allowing for rapid browning and crisping of food surfaces. Oil's low specific heat and high boiling point facilitate efficient conduction and caramelization, essential for flavor development.

Steam-frying uses water vapor combined with a small amount of oil, providing a gentler heat transfer that prevents scorching but limits browning due to lower temperature ceilings. Water's high specific heat ensures even cooking through steam's latent heat, while the minimal oil content adds slight crispness. This method balances moisture retention with moderate caramelization, ideal for delicate textures.

Nutrient Retention: Sautéing vs Steam-Frying Outcomes

Sauteing typically uses higher heat with less water, which can lead to greater nutrient loss through heat exposure but preserves texture and flavor. Steam-frying combines steaming and frying, reducing nutrient degradation by lowering cooking temperature and water-soluble vitamin leaching.

- Vitamin C retention - Steam-frying preserves more vitamin C compared to traditional sauteing due to reduced direct heat exposure.

- Mineral preservation - Minerals like potassium and magnesium remain more intact during steam-frying as less water contact prevents leaching.

- Antioxidant levels - Steam-frying maintains higher antioxidant content by minimizing oxidative damage associated with high-temperature sauteing.

Browning and the Maillard Reaction in Sautéing

Sauteing achieves superior browning through direct contact with high heat, promoting the Maillard reaction more effectively than steam-frying. Steam-frying uses trapped steam to cook food, which limits surface temperature and reduces the intensity of browning and flavor development.

- Enhanced Browning - Sauteing's dry heat environment allows amino acids and sugars to react, forming complex flavors and a crispy crust.

- Heat Transfer Efficiency - Direct pan contact in sauteing maximizes temperature, accelerating the Maillard reaction compared to the moist heat in steam-frying.

- Flavor Complexity - The Maillard reaction in sauteing produces richer, more pronounced flavors not achievable through steam-frying's gentler cooking method.

Choosing sauteing over steam-frying optimizes heat transfer for achieving ideal browning and enhancing savory taste through the Maillard reaction.

Steam-Frying for Delicate Ingredients: Gentle Cooking Benefits

| Steam-Frying for Delicate Ingredients | Steam-frying uses minimal oil and steam pressure to evenly transfer heat, preserving the texture and moisture of delicate vegetables and seafood. This gentle cooking method reduces nutrient loss and prevents overcooking, unlike traditional sauteing which often exposes ingredients to higher direct heat. Controlled steam environment allows for precise heat regulation, enhancing flavor retention and maintaining structural integrity in sensitive foods. |

Related Important Terms

Direct-conduction sautéing

Direct-conduction sauteing involves cooking food in a hot pan with a small amount of fat, allowing efficient heat transfer through direct contact between the food and the pan surface, resulting in rapid browning and flavor development. In contrast, steam-frying combines direct heat with steam moisture, which reduces surface temperature and slows Maillard reactions, producing a different texture and less intense caramelization.

Moist-contact steam-fry

Moist-contact steam-frying employs a combination of direct heat and steam to enhance heat transfer, ensuring rapid cooking while preserving moisture and texture. Unlike traditional sauteing, which relies solely on dry, high-heat conduction, steam-frying reduces the risk of food drying out and promotes more even cooking through the presence of steam.

Oil-bloom Maillard

Sauteing relies on direct contact with hot oil, promoting the oil-bloom Maillard reaction that enhances flavor through efficient heat transfer and browning. Steam-frying uses both steam and oil, resulting in gentler heat transfer that limits oil-bloom Maillard development, producing subtler caramelization and softer textures.

Low-oil steam-searing

Low-oil steam-searing combines the rapid heat transfer of sauteing with the moisture retention of steaming, creating a balance between high-temperature browning and gentle cooking. This method reduces oil usage while promoting even heat distribution, enhancing flavor and texture with less fat absorption compared to traditional sauteing.

Hybrid sauté-steaming

Hybrid saute-steaming combines direct heat transfer through hot oil with steam heat circulation, enhancing cooking efficiency and flavor development by evenly distributing heat and moisture. This method outperforms traditional sauteing by reducing nutrient loss and improving texture through controlled steam generation while maintaining the crispiness from oil contact.

Steam-lifted convection

Steam-frying enhances heat transfer by combining direct contact with a hot surface and steam-lifted convection, allowing for faster and more even cooking than traditional sauteing, which relies primarily on conduction through oil. This steam-lifted convection creates a thin vapor layer that improves heat distribution and reduces cooking time while preserving moisture and texture.

Micro-steam enveloping

Sauteing utilizes direct contact heat from a hot pan to rapidly brown and caramelize food surfaces, enhancing flavor through Maillard reactions, while steam-frying relies on the micro-steam enveloping effect where moisture trapped in a shallow layer enables gentle, even heat transfer without excessive oil. This micro-steam enveloping creates a steam cushion that minimizes surface drying, preserving food moisture and tenderness more effectively than the dry heat in sauteing.

Flash-steam caramelization

Sauteing utilizes direct contact with a hot pan to rapidly transfer heat, enabling flash-steam caramelization that creates complex flavors through the Maillard reaction and browning. In contrast, steam-frying traps moisture, reducing direct heat exposure and slowing caramelization, resulting in less intense surface browning.

Humidity-aided sauté

Humidity-aided saute enhances heat transfer by introducing moisture that creates steam, increasing thermal conductivity and preventing food from drying out while maintaining high cooking temperatures. This method balances direct heat from the pan with steam's vaporization energy, resulting in evenly cooked, tender textures compared to traditional dry sauteing and steam-frying.

Sautéing vs Steam-Frying for heat transfer. Infographic

cookingdiff.com

cookingdiff.com