An aluminum saute pan heats up quickly and provides excellent heat conductivity, making it ideal for precise temperature control during sauteing. Hard-anodized saute pans offer enhanced durability and non-reactive surfaces, preventing food from sticking and resisting corrosion. Choosing between the two depends on the balance between heat responsiveness and long-term wear resistance for optimal cooking performance.

Table of Comparison

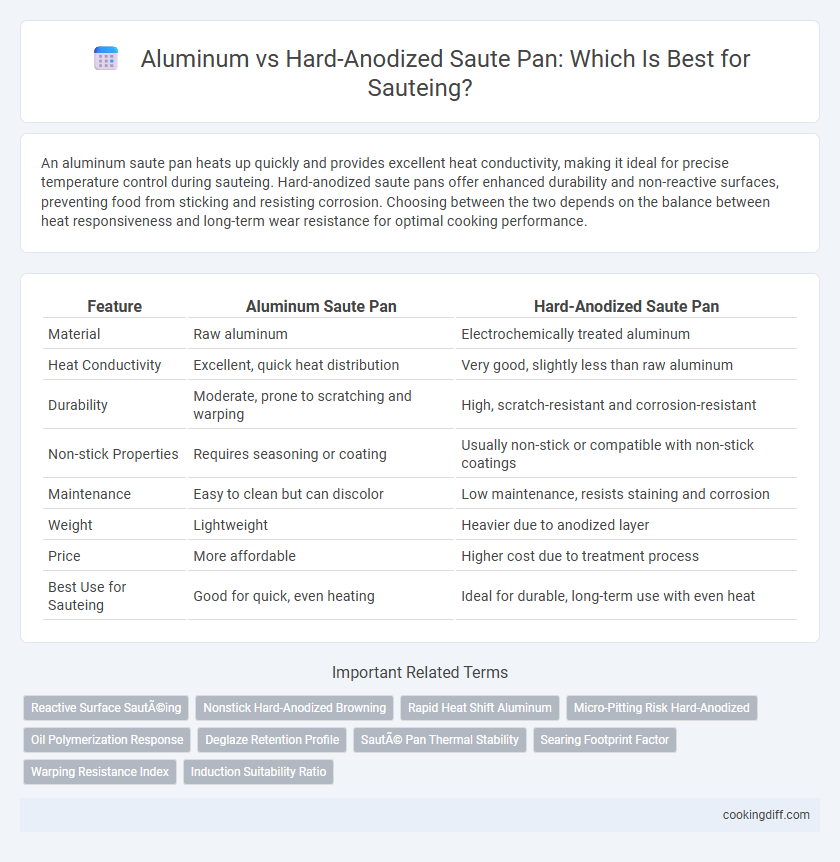

| Feature | Aluminum Saute Pan | Hard-Anodized Saute Pan |

|---|---|---|

| Material | Raw aluminum | Electrochemically treated aluminum |

| Heat Conductivity | Excellent, quick heat distribution | Very good, slightly less than raw aluminum |

| Durability | Moderate, prone to scratching and warping | High, scratch-resistant and corrosion-resistant |

| Non-stick Properties | Requires seasoning or coating | Usually non-stick or compatible with non-stick coatings |

| Maintenance | Easy to clean but can discolor | Low maintenance, resists staining and corrosion |

| Weight | Lightweight | Heavier due to anodized layer |

| Price | More affordable | Higher cost due to treatment process |

| Best Use for Sauteing | Good for quick, even heating | Ideal for durable, long-term use with even heat |

Introduction to Sautéing: Choosing the Right Pan

Which pan material enhances sauteing performance, aluminum or hard-anodized? Aluminum saute pans offer excellent heat conductivity, allowing for quick and even cooking, but can react with acidic foods. Hard-anodized saute pans provide durable, non-reactive surfaces and superior scratch resistance, making them ideal for frequent, high-heat sauteing tasks.

What Is an Aluminum Sauté Pan?

An aluminum saute pan is a lightweight cookware option made from pure aluminum, known for its excellent heat conductivity and quick responsiveness to temperature changes. This pan type often features a non-stick coating to enhance food release and ease of cleaning.

- Lightweight construction - Aluminum pans are easy to handle, reducing fatigue during cooking.

- Excellent heat conduction - They heat evenly and quickly, preventing hot spots for consistent sauteing.

- Non-stick surfaces - Many aluminum pans come with durable non-stick coatings to minimize oil usage and simplify cleanup.

Aluminum saute pans are ideal for cooks seeking fast, even heating and lightweight cookware for sauteing tasks.

What Is a Hard-Anodized Sauté Pan?

A hard-anodized saute pan is crafted from aluminum that has undergone an electrochemical process to harden its surface, making it highly durable and resistant to scratches and corrosion. This treatment creates a non-reactive, non-stick surface that enhances heat distribution and retention, ideal for sauteing delicate ingredients. Compared to regular aluminum pans, hard-anodized options offer superior durability and even cooking performance, making them a preferred choice for professional and home chefs.

Heat Conductivity: Aluminum vs Hard-Anodized

Aluminum saute pans offer superior heat conductivity, allowing for rapid and even heating across the cooking surface, which is essential for precise sauteing. This metal's low thermal mass ensures quick temperature adjustments, reducing the risk of uneven cooking or hot spots.

Hard-anodized saute pans, while less conductive than aluminum, provide enhanced durability and a non-reactive cooking surface, maintaining consistent heat distribution over time. Their corrosion-resistant anodized layer helps retain heat efficiently, but may require slightly longer to adjust temperature compared to pure aluminum pans.

Durability and Longevity Comparison

Aluminum saute pans offer excellent heat conduction but tend to be less durable and prone to warping over time. Hard-anodized saute pans provide superior resistance to wear and corrosion, ensuring longer-lasting performance in demanding kitchen environments.

- Aluminum pans warp easily - Thin aluminum is vulnerable to high heat, causing deformation and reducing lifespan.

- Hard-anodized pans resist damage - The anodization process creates a hard surface that protects against scratches and corrosion.

- Longevity favors hard-anodized - Hard-anodized pans maintain shape and integrity longer, making them a more durable investment for sauteing.

Nonstick Properties: Which Pan Performs Better?

| Pan Type | Nonstick Properties | Durability |

|---|---|---|

| Aluminum Saute Pan | Offers moderate nonstick performance but is prone to scratching and wearing over time, causing food to stick more easily. | Less durable due to soft metal surface, requiring frequent seasoning or nonstick coatings. |

| Hard-Anodized Saute Pan | Exhibits superior nonstick capabilities thanks to a dense, non-reactive anodized layer that resists food adhesion and facilitates easy release. | Highly durable with a hard surface resistant to scratches, corrosion, and wear, maintaining nonstick quality longer. |

Weight and Handling Differences

Aluminum saute pans are lightweight, offering superior maneuverability and ease of handling during quick cooking tasks. Their low weight helps reduce fatigue when tossing or stirring ingredients rapidly.

Hard-anodized saute pans are heavier due to their dense, durable construction, providing better stability on the stove. This weight contributes to even heat distribution while requiring more effort to maneuver compared to aluminum pans.

Ease of Cleaning and Maintenance

Aluminum saute pans feature a smooth surface that allows for quick and easy cleaning, often requiring just a simple wash with mild detergent and a soft sponge. Their lightweight design also simplifies handling during maintenance tasks.

Hard-anodized saute pans offer superior durability and resistance to scratches, making them less prone to staining and easier to maintain over time. Their non-stick surfaces reduce food buildup, which minimizes scrubbing effort and extends the pan's lifespan. Routine cleaning with gentle, non-abrasive materials preserves the hard-anodized coating and ensures consistent performance for sauteing.

Price Comparison: Aluminum vs Hard-Anodized Sauté Pans

Aluminum saute pans are generally more affordable, making them a popular choice for budget-conscious cooks. Hard-anodized saute pans tend to have a higher price point due to their durability and non-stick properties.

- Lower cost of aluminum pans - Aluminum saute pans often cost significantly less than hard-anodized options, appealing to beginners and casual users.

- Premium pricing for hard-anodized pans - Hard-anodized pans are priced higher because of their enhanced strength and corrosion resistance.

- Long-term value consideration - Despite the initial investment, hard-anodized pans may offer better longevity and performance, potentially reducing replacement frequency.

Related Important Terms

Reactive Surface Sautéing

Aluminum saute pans react with acidic or alkaline ingredients, causing surface degradation and imparting off-flavors during reactive surface sauteing, while hard-anodized saute pans feature a chemically hardened, non-reactive surface that resists corrosion and maintains flavor integrity. The durability and non-reactivity of hard-anodized pans make them superior for sauteing dishes with tomatoes, citrus, or wine, preventing metallic taste and surface pitting common in traditional aluminum cookware.

Nonstick Hard-Anodized Browning

Hard-anodized saute pans offer superior nonstick properties and even heat distribution, enabling better browning and preventing food from sticking compared to aluminum saute pans. Aluminum pans heat quickly but often lack durable nonstick surfaces, making hard-anodized options ideal for achieving consistent caramelization and easy food release during sauteing.

Rapid Heat Shift Aluminum

Rapid Heat Shift Aluminum saute pans excel in quickly reaching high temperatures, providing excellent heat conduction essential for precise sauteing techniques. Hard-anodized saute pans offer enhanced durability and non-reactive surfaces, but aluminum's superior thermal responsiveness ensures faster browning and consistent cooking results.

Micro-Pitting Risk Hard-Anodized

Hard-anodized saute pans offer superior resistance to micro-pitting compared to aluminum saute pans, ensuring enhanced durability and a smoother cooking surface over time. Micro-pitting in aluminum pans can lead to surface degradation and reduced non-stick performance, making hard-anodized options preferable for long-term sauteing.

Oil Polymerization Response

Aluminum saute pans heat quickly but can cause oil to polymerize faster due to uneven heat distribution, affecting the non-stick surface over time. Hard-anodized saute pans provide more even heat distribution and a durable surface that reduces oil polymerization, enhancing cooking performance and pan longevity.

Deglaze Retention Profile

Aluminum saute pans excel in rapid and even heat distribution, promoting quick deglazing and efficient release of fond, while hard-anodized saute pans offer superior nonstick properties that minimize fond adhesion yet retain sufficient heat for consistent deglaze retention. The hard-anodized surface enhances durability and corrosion resistance, maintaining optimal deglaze profiles over time, whereas aluminum pans may require more frequent seasoning or care to preserve similar performance.

Sauté Pan Thermal Stability

Hard-anodized saute pans offer superior thermal stability compared to aluminum saute pans, maintaining consistent heat distribution and reducing hot spots during high-heat cooking. Aluminum pans heat quickly but may warp under intense heat, making hard-anodized pans ideal for precise sauteing and better heat retention.

Searing Footprint Factor

Aluminum saute pans provide excellent heat conductivity, ensuring a uniform searing footprint that quickly browns food with minimal hot spots. Hard-anodized saute pans offer superior surface durability and non-reactivity, maintaining an even searing footprint while resisting warping and corrosion during high-temperature sauteing.

Warping Resistance Index

Hard-anodized saute pans exhibit a significantly higher Warping Resistance Index compared to aluminum saute pans, making them more durable and stable under high heat during sauteing. Aluminum pans, while lightweight and conductive, are more prone to warping from rapid temperature changes, reducing their lifespan and cooking performance.

Aluminum sauté pan vs Hard-anodized sauté pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com