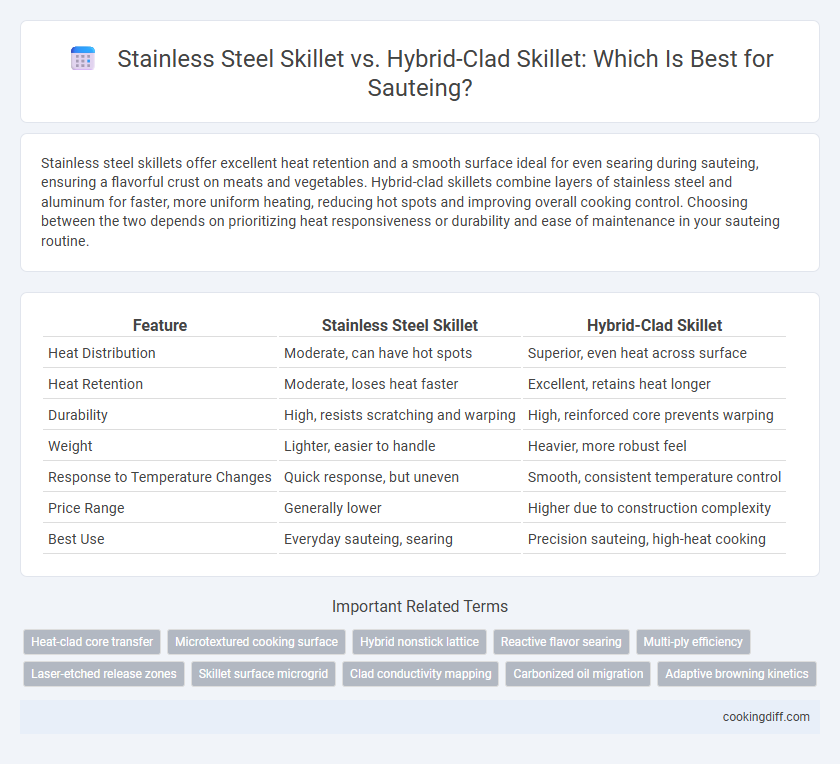

Stainless steel skillets offer excellent heat retention and a smooth surface ideal for even searing during sauteing, ensuring a flavorful crust on meats and vegetables. Hybrid-clad skillets combine layers of stainless steel and aluminum for faster, more uniform heating, reducing hot spots and improving overall cooking control. Choosing between the two depends on prioritizing heat responsiveness or durability and ease of maintenance in your sauteing routine.

Table of Comparison

| Feature | Stainless Steel Skillet | Hybrid-Clad Skillet |

|---|---|---|

| Heat Distribution | Moderate, can have hot spots | Superior, even heat across surface |

| Heat Retention | Moderate, loses heat faster | Excellent, retains heat longer |

| Durability | High, resists scratching and warping | High, reinforced core prevents warping |

| Weight | Lighter, easier to handle | Heavier, more robust feel |

| Response to Temperature Changes | Quick response, but uneven | Smooth, consistent temperature control |

| Price Range | Generally lower | Higher due to construction complexity |

| Best Use | Everyday sauteing, searing | Precision sauteing, high-heat cooking |

Introduction to Sautéing: The Importance of Pan Choice

Choosing between a stainless steel skillet and a hybrid-clad skillet significantly impacts the sauteing process due to differences in heat conductivity and retention. Stainless steel skillets offer excellent durability and high heat tolerance, making them ideal for browning and deglazing, while hybrid-clad skillets provide superior heat distribution and non-reactive surfaces that minimize hotspots. Understanding these pan characteristics ensures optimal temperature control and enhances the flavor and texture of sauteed dishes.

What Is a Stainless Steel Skillet?

A stainless steel skillet is a durable cookware option known for its non-reactive surface and even heat distribution, ideal for sauteing a variety of ingredients. It resists rust and corrosion, offering a long-lasting cooking tool that maintains flavor integrity without imparting metallic tastes.

- Material Composition - Crafted primarily from high-quality stainless steel alloys, these skillets provide excellent heat retention and resistance to staining.

- Cooking Performance - Stainless steel skillets distribute heat evenly, enabling precise control during sauteing to achieve desirable browning and caramelization.

- Maintenance - They require regular cleaning with appropriate methods to prevent discoloration and maintain their polished surface over time.

What Is a Hybrid-Clad Skillet?

What is a hybrid-clad skillet and how does it compare to a stainless steel skillet for sauteing? A hybrid-clad skillet features a stainless steel cooking surface with an aluminum core layered between stainless steel, offering superior heat distribution and retention. This design prevents hot spots, making it ideal for precise sauteing compared to traditional stainless steel skillets that may heat unevenly.

Heat Distribution: Stainless Steel vs Hybrid-Clad

Hybrid-clad skillets feature multiple bonded layers of stainless steel and aluminum, providing superior heat distribution and minimizing hot spots during sauteing. Stainless steel skillets, while durable and resistant to corrosion, often heat unevenly due to their single metal construction. This results in less consistent cooking performance compared to the more efficient thermal conductivity of hybrid-clad pans.

Responsiveness and Temperature Control

Stainless steel skillets heat evenly but are slower to respond to temperature changes, making precise temperature control challenging. Hybrid-clad skillets, with their layered construction, offer superior responsiveness and rapid heat adjustments ideal for sauteing.

- Even Heating - Stainless steel skillets distribute heat uniformly but retain heat longer.

- Quick Temperature Adjustment - Hybrid-clad skillets adapt rapidly to heat changes, reducing risk of overcooking.

- Thermal Conductivity - The aluminum or copper core in hybrid-clad skillets enhances thermal control compared to pure stainless steel.

Choosing a hybrid-clad skillet improves sauteing performance by enabling better temperature management and cooking precision.

Surface Stickiness: Browning and Release

Stainless steel skillets excel at developing a deeply browned crust due to their high heat tolerance but can sometimes cause food to stick if not properly preheated or oiled. Hybrid-clad skillets, with their layered construction, offer more even heat distribution, reducing surface stickiness and improving food release during sauteing.

- Stainless steel skillet browning - Achieves superior Maillard reaction for enhanced flavor but requires careful temperature control to prevent sticking.

- Hybrid-clad skillet heat distribution - Provides consistent warmth across the surface, minimizing hot spots that cause sticking during sauteing.

- Surface release comparison - Hybrid-clad surfaces facilitate easier food release compared to traditional stainless steel, optimizing saute texture and cleanup.

Durability and Longevity in Sautéing

Stainless steel skillets offer exceptional durability, resisting warping and corrosion even under high heat during sauteing. Their solid construction ensures a long lifespan, making them ideal for frequent, rigorous cooking.

Hybrid-clad skillets combine stainless steel with aluminum or copper cores, enhancing heat distribution while maintaining robust structural integrity. This design improves longevity by preventing hotspots and warping, ensuring consistent performance over time.

Versatility Across Cooking Methods

Stainless steel skillets offer excellent heat retention and develop a natural non-stick surface with proper seasoning, making them ideal for high-heat sauteing and searing. Their single-layer construction allows for quick temperature adjustments but may result in uneven heat distribution.

Hybrid-clad skillets combine an aluminum core with stainless steel layers, providing superior heat conduction and even cooking across various methods, including sauteing, frying, and deglazing. This versatility ensures consistent results on both stovetop and oven, making them a preferred choice for multitasking in the kitchen.

Maintenance and Cleaning Differences

Stainless steel skillets require thorough cleaning to remove food residues and prevent staining, often needing scrubbing with abrasive pads or specialized cleaners. Hybrid-clad skillets, featuring aluminum or copper cores sandwiched between stainless steel layers, distribute heat evenly and tend to resist sticking, making them slightly easier to clean after sauteing.

Maintenance of stainless steel skillets involves regular seasoning and immediate cleaning to avoid discoloration and corrosion, while hybrid-clad skillets demand less effort due to superior heat conduction and less food adherence. Hybrid-clad designs also reduce hot spots that cause burnt residues, simplifying the cleaning process. Proper care of both types ensures longevity, but hybrid-clad skillets offer enhanced convenience for sauteing enthusiasts focused on quick and effective maintenance.

Related Important Terms

Heat-clad core transfer

A hybrid-clad skillet with an aluminum or copper core provides superior heat transfer and even temperature distribution compared to a stainless steel skillet, minimizing hot spots during sauteing. This enhanced heat conductivity ensures precise control over cooking temperatures, resulting in perfectly seared ingredients with consistent texture and flavor.

Microtextured cooking surface

The microtextured cooking surface of a stainless steel skillet enhances browning and reduces sticking by creating tiny pockets for oil and food to interact evenly. Hybrid-clad skillets combine this microtexture with layered metals, offering superior heat distribution and improved sauteing performance.

Hybrid nonstick lattice

A hybrid-clad skillet with a nonstick lattice surface offers superior heat distribution and release properties compared to a traditional stainless steel skillet, making sauteing more efficient and less prone to sticking. The lattice design enhances durability while minimizing the need for excessive oil, allowing for healthier cooking with even browning and easy cleanup.

Reactive flavor searing

A hybrid-clad skillet offers superior heat distribution and retention, creating a more consistent and efficient sear that enhances reactive flavor development during sauteing. In comparison, stainless steel skillets may have hot spots that can cause uneven searing and less pronounced flavor reactions.

Multi-ply efficiency

Hybrid-clad skillets feature multiple layers of stainless steel and aluminum that provide superior heat conductivity and even distribution, resulting in precise temperature control essential for sauteing. Stainless steel skillets with single-ply construction tend to have hot spots and slower heat response, making hybrid-clad designs significantly more efficient for consistent, high-heat cooking tasks.

Laser-etched release zones

Hybrid-clad skillets with laser-etched release zones offer superior food release during sauteing by minimizing sticking and promoting even heat distribution compared to traditional stainless steel skillets. These precision-engineered zones enhance browning and reduce the need for excessive oil, making them ideal for professional and home cooks seeking optimal performance.

Skillet surface microgrid

Stainless steel skillets feature a smooth surface microgrid that promotes even browning and prevents food from sticking during sauteing, enhancing flavor development. Hybrid-clad skillets combine multiple metals with a refined microgrid surface that improves heat distribution and reduces hotspots for precise temperature control.

Clad conductivity mapping

Hybrid-clad skillets feature multi-layered construction with an aluminum core, offering superior heat conductivity and even heat distribution essential for precise sauteing. Stainless steel skillets, while durable and resistant to corrosion, typically exhibit lower thermal conductivity, resulting in less uniform heat transfer and potential hot spots during cooking.

Carbonized oil migration

A hybrid-clad skillet with an aluminum core offers superior heat distribution and reduces carbonized oil migration compared to a stainless steel skillet, which can develop uneven hotspots that accelerate oil breakdown. The enhanced thermal conductivity of hybrid-clad construction minimizes localized overheating, maintaining oil integrity and preserving flavor during sauteing.

Stainless steel skillet vs hybrid-clad skillet for sautéing. Infographic

cookingdiff.com

cookingdiff.com