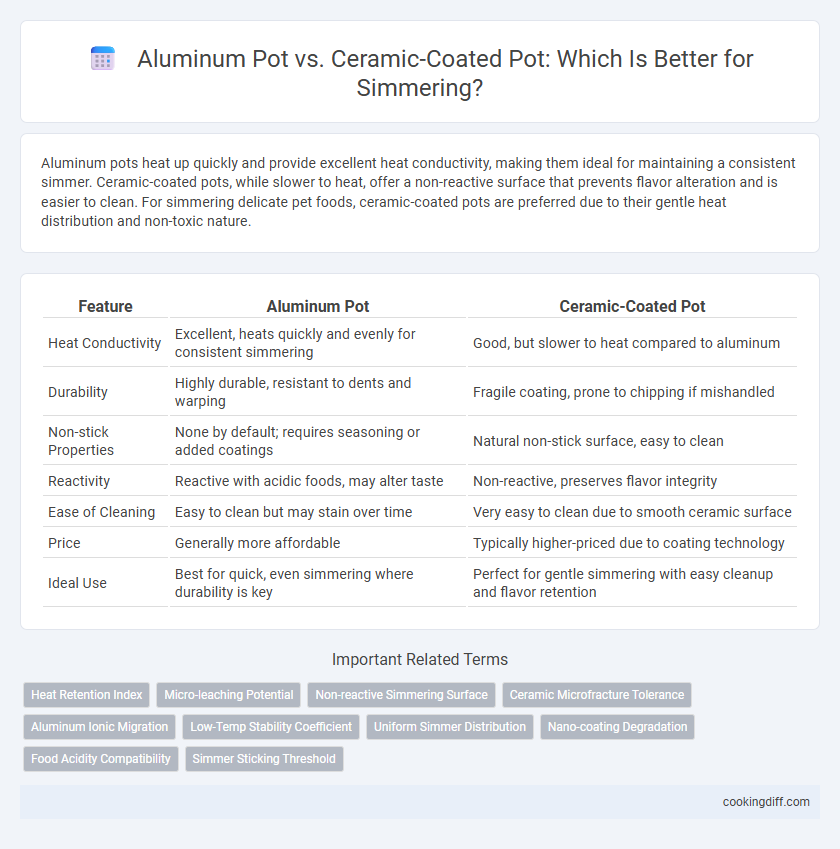

Aluminum pots heat up quickly and provide excellent heat conductivity, making them ideal for maintaining a consistent simmer. Ceramic-coated pots, while slower to heat, offer a non-reactive surface that prevents flavor alteration and is easier to clean. For simmering delicate pet foods, ceramic-coated pots are preferred due to their gentle heat distribution and non-toxic nature.

Table of Comparison

| Feature | Aluminum Pot | Ceramic-Coated Pot |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly for consistent simmering | Good, but slower to heat compared to aluminum |

| Durability | Highly durable, resistant to dents and warping | Fragile coating, prone to chipping if mishandled |

| Non-stick Properties | None by default; requires seasoning or added coatings | Natural non-stick surface, easy to clean |

| Reactivity | Reactive with acidic foods, may alter taste | Non-reactive, preserves flavor integrity |

| Ease of Cleaning | Easy to clean but may stain over time | Very easy to clean due to smooth ceramic surface |

| Price | Generally more affordable | Typically higher-priced due to coating technology |

| Ideal Use | Best for quick, even simmering where durability is key | Perfect for gentle simmering with easy cleanup and flavor retention |

Introduction to Simmering: Why Pot Material Matters

Simmering requires consistent low to medium heat, making pot material crucial for precise temperature control. Aluminum pots heat quickly and evenly, ideal for maintaining a gentle simmer without hotspots.

Ceramic-coated pots offer excellent non-stick properties and slow heat retention, reducing the risk of burning or sticking. Choosing the right pot enhances cooking efficiency and preserves the delicate flavors developed during simmering.

Aluminum Pots: Key Features and Benefits for Simmering

Aluminum pots offer excellent thermal conductivity, ensuring even heat distribution essential for consistent simmering. Their lightweight design allows for easy handling and precise temperature control during lengthy cooking processes.

Durability and affordability make aluminum pots a popular choice for simmering various dishes, from soups to sauces. They also heat up quickly, reducing energy consumption and cooking time.

Ceramic-Coated Pots: Key Features and Benefits for Simmering

Ceramic-coated pots offer superior heat retention and even distribution, ideal for maintaining a steady simmer without scorching. Their non-reactive surfaces prevent flavor alterations, preserving the natural taste of simmered dishes.

- Non-stick surface - Ensures food does not adhere during simmering, making cleanup easy and preventing burning.

- Chemical-free coating - Provides a safe cooking environment by avoiding harmful substances like PTFE and PFOA.

- Durability - Resists scratches and high temperatures, extending the pot's lifespan even with frequent simmering use.

Heat Distribution: Aluminum vs Ceramic-Coated Pots

Aluminum pots offer superior heat conduction, ensuring even heat distribution critical for consistent simmering. Ceramic-coated pots provide a more tempered heat distribution, reducing hotspots but often requiring more time to reach stable simmer temperatures.

- Aluminum's high thermal conductivity - Enables rapid and uniform heat spread throughout the pot, ideal for delicate simmering tasks.

- Ceramic coating acts as insulation - Moderates heat transfer, which can prevent burning but may cause uneven simmering if not monitored closely.

- Heat retention differences - Aluminum cools and heats quickly, while ceramic-coated pots maintain temperature longer, affecting simmer control.

Heat Retention: Which Pot Keeps a Simmer Better?

| Pot Type | Heat Retention | Simmering Efficiency |

|---|---|---|

| Aluminum Pot | Moderate heat retention, heats up quickly but loses heat faster. | Requires frequent heat adjustments to maintain steady simmer due to rapid temperature changes. |

| Ceramic-Coated Pot | Excellent heat retention, distributes heat evenly and maintains warmth longer. | More consistent simmering with reduced need for temperature adjustments, ideal for slow cooking. |

Reactivity with Foods: Aluminum and Ceramic-Coated Comparisons

Aluminum pots are highly reactive with acidic foods, often causing discoloration and metallic taste during simmering. Ceramic-coated pots provide a non-reactive surface, preventing any interaction with food and preserving flavors. This makes ceramic-coated cookware a safer choice for simmering acidic ingredients like tomatoes or vinegar-based sauces.

Nonstick Performance During Simmering

Aluminum pots provide excellent heat conduction for even simmering but often lack a durable nonstick surface, leading to food sticking during prolonged cooking. Ceramic-coated pots offer superior nonstick performance during simmering, preventing food from adhering while maintaining gentle, consistent heat distribution.

- Aluminum heat conductivity - Aluminum quickly and evenly distributes heat but may cause sticking without a nonstick coating.

- Ceramic nonstick benefits - Ceramic coatings reduce food adhesion, making simmering delicate sauces easier and cleanup simpler.

- Durability considerations - Ceramic coatings can degrade over time with high heat, while aluminum surfaces may scratch or discolor.

Ceramic-coated pots generally offer better nonstick performance for simmering, enhancing cooking results and ease of maintenance.

Durability and Longevity: Aluminum vs Ceramic-Coated

Aluminum pots offer excellent heat conductivity but are prone to scratching and warping over time, which can reduce their durability. Ceramic-coated pots provide a protective layer that resists abrasion and corrosion, enhancing longevity.

Aluminum cookware may deteriorate faster when exposed to acidic foods or high heat, impacting its lifespan. Ceramic coatings, though durable, can chip if mishandled, but generally maintain their non-stick properties longer. Proper care extends the functional life of both materials, with ceramic-coated pots often outperforming aluminum in sustained use for simmering.

Maintenance and Ease of Cleaning

Aluminum pots are lightweight and conduct heat quickly but can discolor and degrade over time if not cleaned properly. Ceramic-coated pots offer a non-stick surface that simplifies cleaning and prevents residue buildup, making maintenance easier. However, ceramic coatings require gentle handling and avoid abrasive scrubbing to preserve the finish and ensure long-term durability.

Related Important Terms

Heat Retention Index

Aluminum pots offer a lower Heat Retention Index, allowing quick temperature adjustments during simmering, while ceramic-coated pots provide higher heat retention, maintaining a consistent low simmer for extended cooking times. Choosing between them depends on whether rapid heat changes or steady heat stability is preferred for precise simmering control.

Micro-leaching Potential

Aluminum pots exhibit a higher micro-leaching potential during simmering, releasing trace amounts of aluminum ions that may affect food quality and health. Ceramic-coated pots offer a non-reactive surface that minimizes micro-leaching, ensuring safer and purer simmered meals.

Non-reactive Simmering Surface

Aluminum pots often react with acidic foods, potentially altering flavor during simmering, while ceramic-coated pots provide a non-reactive surface that preserves the purity and taste of simmered dishes. The ceramic coating also offers excellent heat distribution, ensuring even simmering without the risk of metal leaching into the food.

Ceramic Microfracture Tolerance

Ceramic-coated pots offer superior ceramic microfracture tolerance compared to aluminum pots, maintaining durability and a smooth surface during prolonged simmering. This resistance reduces the risk of cracks and enhances even heat distribution, ensuring consistent cooking performance.

Aluminum Ionic Migration

Aluminum pots, prone to ionic migration, can release aluminum ions into food during simmering, potentially affecting flavor and health. Ceramic-coated pots prevent aluminum ion transfer, offering a safer and more inert surface ideal for prolonged simmering without altering food composition.

Low-Temp Stability Coefficient

Aluminum pots exhibit a higher thermal conductivity but a lower low-temp stability coefficient compared to ceramic-coated pots, resulting in less consistent heat retention during simmering. Ceramic-coated pots provide superior low-temperature stability, ensuring even and steady heat distribution crucial for precise simmering control.

Uniform Simmer Distribution

Aluminum pots provide excellent heat conductivity, ensuring uniform simmer distribution and preventing hot spots during cooking. Ceramic-coated pots offer a non-stick surface but often have less efficient heat distribution, which can lead to uneven simmering.

Nano-coating Degradation

Aluminum pots with nano-coatings may experience faster degradation during simmering due to prolonged exposure to low heat and acidic ingredients, compromising their non-stick performance and durability. Ceramic-coated pots are more resistant to nano-coating degradation under simmering conditions, maintaining corrosion resistance and an intact surface for safer, long-term use.

Food Acidity Compatibility

Aluminum pots may react with acidic foods during simmering, potentially altering taste and discoloring the pot, while ceramic-coated pots provide a non-reactive surface that preserves the flavor and appearance of acidic dishes. Choosing ceramic-coated cookware ensures better compatibility with tomatoes, citrus, and vinegar-based recipes commonly simmered.

Aluminum pot vs Ceramic-coated pot for simmering. Infographic

cookingdiff.com

cookingdiff.com