A stainless steel pan offers superior heat conductivity and durability for simmering, allowing precise temperature control and even cooking. Nonstick sauciers provide easy food release and simple cleanup but may not achieve the same browning or flavor development as stainless steel. Choosing between the two depends on the importance of heat control and cooking techniques versus convenience and maintenance preferences.

Table of Comparison

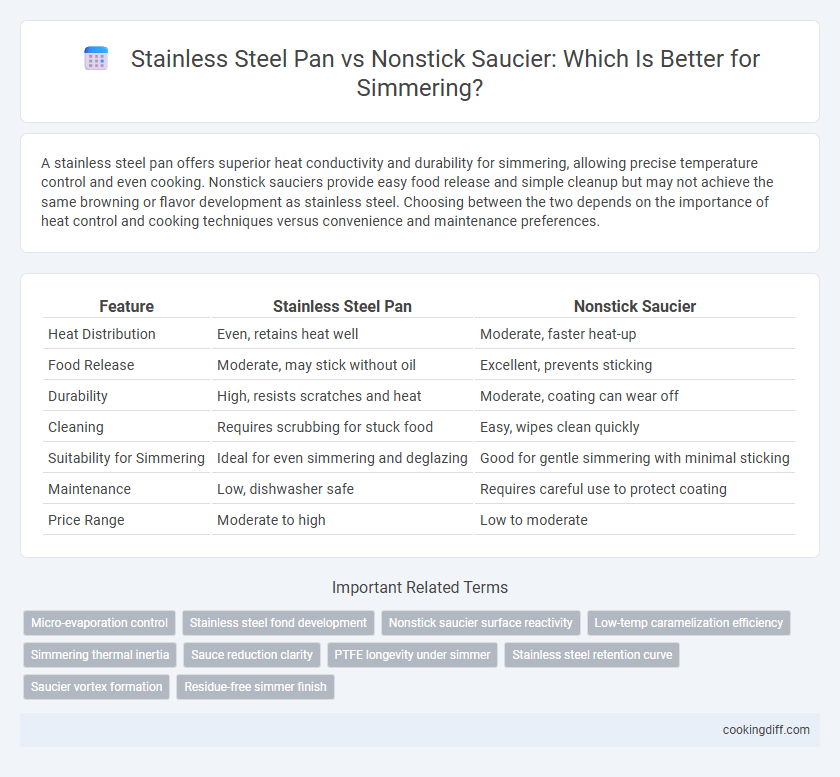

| Feature | Stainless Steel Pan | Nonstick Saucier |

|---|---|---|

| Heat Distribution | Even, retains heat well | Moderate, faster heat-up |

| Food Release | Moderate, may stick without oil | Excellent, prevents sticking |

| Durability | High, resists scratches and heat | Moderate, coating can wear off |

| Cleaning | Requires scrubbing for stuck food | Easy, wipes clean quickly |

| Suitability for Simmering | Ideal for even simmering and deglazing | Good for gentle simmering with minimal sticking |

| Maintenance | Low, dishwasher safe | Requires careful use to protect coating |

| Price Range | Moderate to high | Low to moderate |

Introduction: Choosing the Right Pan for Simmering

Selecting the right pan is crucial for perfect simmering results, as it affects heat distribution and food texture. Stainless steel pans and nonstick sauciers each offer distinct benefits depending on the cooking technique.

Stainless steel pans provide excellent heat retention and even cooking, ideal for dishes requiring prolonged simmering without scorching. Nonstick sauciers feature a curved shape and smooth coating that prevent food from sticking while making stirring effortless. Both options enhance simmering but cater to different recipe needs and maintenance preferences.

Simmering Fundamentals: Why Pan Material Matters

Stainless steel pans offer excellent heat conductivity and durability, making them ideal for maintaining consistent simmering temperatures crucial for delicate reductions and sauces. Their non-reactive surface prevents flavor alteration, ensuring the integrity of your simmered dishes.

Nonstick sauciers provide effortless food release, minimizing the risk of burning or sticking during long simmering processes, which is beneficial for simmering sticky or delicate ingredients. However, their heat distribution is often less uniform, potentially leading to uneven simmering and inconsistent results.

Stainless Steel Pan: Strengths for Simmering Sauce

Why is a stainless steel pan preferred for simmering sauces over a nonstick saucier? Stainless steel pans offer superior heat retention and even distribution, which is essential for maintaining a steady simmer without hot spots. Their ability to withstand high temperatures allows sauces to reduce and thicken efficiently, developing richer flavors compared to nonstick surfaces.

Nonstick Saucier: Benefits for Gentle Simmering

Nonstick sauciers excel at gentle simmering by providing even heat distribution and preventing food from sticking to the surface. Their smooth coating allows delicate sauces and reductions to cook slowly without scorching or burning.

- Superior heat control - Nonstick surfaces maintain consistent low temperatures essential for slow simmering.

- Easy cleanup - Food residue is less likely to cling, simplifying post-cooking maintenance.

- Enhanced flavor retention - Nonstick coatings prevent ingredients from overcooking and losing their subtle flavors during simmering.

Heat Distribution: Stainless Steel vs Nonstick

Stainless steel pans offer superior heat distribution due to their multi-layered construction, allowing for even cooking and precise temperature control during simmering. This prevents hot spots and ensures that delicate sauces or reductions cook uniformly without burning.

Nonstick sauciers generally have a lighter base, which can lead to less consistent heat distribution and potential hot spots during longer simmering sessions. Their coating excels in easy food release, but may not handle high or steady heat as evenly as stainless steel.

Temperature Control: Simmering Precision Compared

Stainless steel pans offer superior temperature control during simmering, allowing precise adjustments to maintain consistent low heat essential for delicate sauces. Nonstick sauciers heat quickly but often have uneven heat distribution, risking hot spots that can disrupt slow simmering processes. For recipes requiring meticulous temperature precision, stainless steel is preferred to achieve flawless simmering results.

Maintenance and Durability in Simmering Tasks

Stainless steel pans offer superior durability and resist warping under prolonged simmering heat, making them ideal for frequent cooking tasks. Nonstick sauciers require gentle handling and specific cleaning methods to maintain their coating and prevent damage during simmering.

- Stainless Steel Durability - These pans withstand high heat and abrasive cleaning, ensuring long-lasting performance in simmering applications.

- Nonstick Maintenance - Nonstick sauciers need careful use of non-metal utensils and mild detergents to preserve their nonstick surface over time.

- Heat Retention - Stainless steel distributes heat evenly for consistent simmering, while nonstick surfaces may degrade if overheated.

Choosing between stainless steel and nonstick sauciers hinges on balancing ease of maintenance with the durability demands of simmering.

Flavor Development: Impact of Pan Surface

Stainless steel pans promote superior flavor development during simmering by enabling the Maillard reaction and fond formation, which enrich sauces with complex, browned flavors. Nonstick sauciers prevent food from adhering, resulting in less fond and a milder taste profile. The durable surface of stainless steel also withstands high heat, allowing for gradual flavor concentration without compromising pan integrity.

Best Uses: When to Choose Stainless Steel or Nonstick

| Stainless Steel Pan | Ideal for searing and deglazing; maintains high heat and resists scratching, making it perfect for sauces that require reduction and frequent stirring during simmering. |

| Nonstick Saucier | Best for low to medium heat simmering of delicate sauces and custards to prevent sticking and burning; offers easy cleanup and even heat distribution ideal for gentle cooking. |

Related Important Terms

Micro-evaporation control

Stainless steel pans offer superior micro-evaporation control during simmering due to their higher thermal conductivity and even heat distribution, allowing precise temperature adjustments and consistent moisture retention. Nonstick sauciers provide ease of food release but typically have less efficient heat transfer, which can result in less controlled evaporation and uneven simmering results.

Stainless steel fond development

Stainless steel pans excel at simmering due to their ability to develop fond, a caramelized layer of browned bits that enhances flavor complexity and depth in sauces and reductions. Nonstick sauciers, while preventing food from sticking, do not produce fond, resulting in less flavorful simmered dishes.

Nonstick saucier surface reactivity

Nonstick sauciers feature a chemically inert surface that prevents food from reacting with the pan, ensuring flavors remain pure during simmering. This non-reactive coating contrasts with stainless steel pans, which can sometimes interact with acidic ingredients, potentially altering taste and requiring more careful temperature control.

Low-temp caramelization efficiency

Stainless steel pans excel in low-temperature caramelization due to their high heat conductivity and even heat distribution, allowing precise control over simmering processes. Nonstick sauciers, while preventing food from sticking, often have lower heat tolerance, which can limit the efficiency and depth of caramelization at gentle simmering temperatures.

Simmering thermal inertia

Stainless steel pans exhibit higher thermal inertia during simmering, providing consistent heat retention and even temperature control, ideal for slow cooking and reducing hot spots. Nonstick sauciers heat up quickly but lose heat rapidly, requiring more frequent adjustments to maintain a steady simmer.

Sauce reduction clarity

Stainless steel pans provide superior heat retention and even distribution, promoting precise control during simmering that enhances sauce reduction clarity by preventing burning and allowing natural caramelization. Nonstick sauciers, while easier to clean, often lack the high-heat tolerance and browning capability required for developing rich, clear reductions, potentially resulting in a less flavorful and cloudy sauce.

PTFE longevity under simmer

Stainless steel pans offer superior durability and maintain their heat evenly during simmering, preventing hotspots and ensuring consistent cooking without degrading surface coatings. Nonstick sauciers with PTFE coatings provide excellent release properties but can experience gradual wear and reduced longevity when exposed to prolonged low heat during simmering, potentially leading to diminished performance over time.

Stainless steel retention curve

Stainless steel pans provide superior heat retention and an even temperature curve essential for precise simmering, allowing consistent low simmer without hot spots. Unlike nonstick sauciers, stainless steel's capacity to maintain stable heat enhances the gradual reduction of sauces and prevents burning or uneven cooking.

Saucier vortex formation

Stainless steel pans provide intense heat retention essential for achieving the precise temperature control needed in simmering, but nonstick sauciers excel in vortex formation, allowing gentle circulation of liquids that prevents burning and promotes even cooking. The curved sides of a saucier create a natural vortex, enhancing simmer stability and efficient reduction, which is particularly beneficial for delicate sauces and custards.

Stainless steel pan vs Nonstick saucier for simmering. Infographic

cookingdiff.com

cookingdiff.com