A standard thermometer provides direct temperature readings by being submerged in the liquid, offering precise and consistent measurements critical for maintaining a perfect simmer. Infrared thermometers measure surface temperature without contact, providing quick readings but potentially less accuracy in detecting the true liquid temperature beneath the surface. For simmering pet care solutions where stable, accurate heat is vital, a standard thermometer is often preferred to ensure proper and safe temperature control.

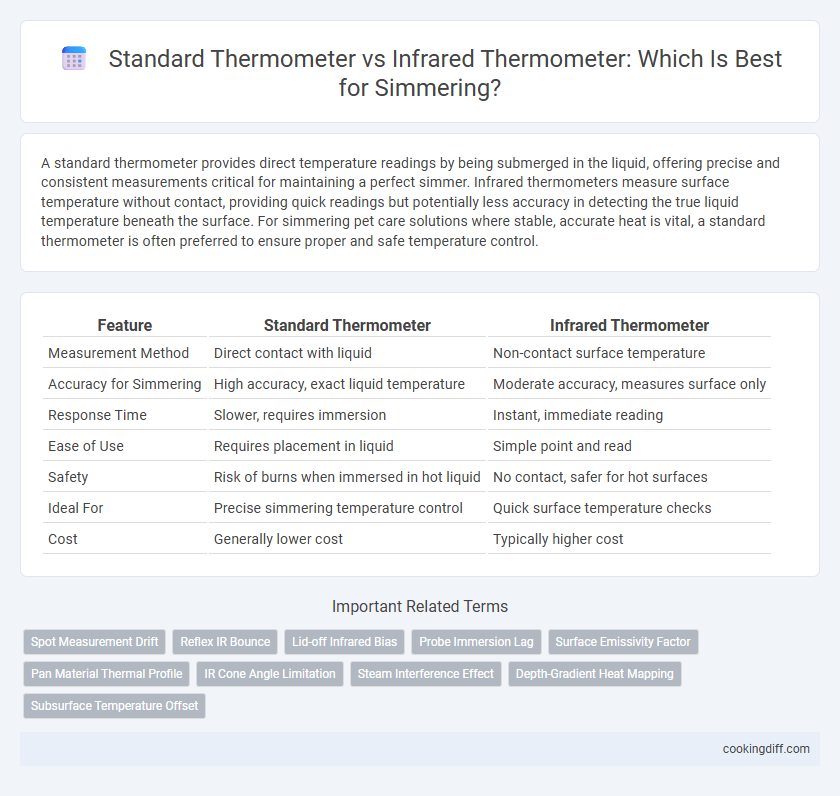

Table of Comparison

| Feature | Standard Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Method | Direct contact with liquid | Non-contact surface temperature |

| Accuracy for Simmering | High accuracy, exact liquid temperature | Moderate accuracy, measures surface only |

| Response Time | Slower, requires immersion | Instant, immediate reading |

| Ease of Use | Requires placement in liquid | Simple point and read |

| Safety | Risk of burns when immersed in hot liquid | No contact, safer for hot surfaces |

| Ideal For | Precise simmering temperature control | Quick surface temperature checks |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Thermometers in Simmering

Simmering requires precise temperature control to maintain gentle heat, usually between 185degF and 205degF (85degC to 96degC). Choosing the right thermometer can impact cooking accuracy and ease of use in the kitchen.

- Standard Thermometer - Provides direct temperature readings by immersion, ensuring accurate measurement of liquid temperatures during simmering.

- Infrared Thermometer - Offers a quick, non-contact surface temperature reading but may not reflect the true internal temperature of the simmering liquid.

- Temperature Range - Both thermometers must be capable of detecting low temperatures typical in simmering to prevent overheating or undercooking.

The Science of Simmering: Temperature Control

Standard thermometers provide direct contact temperature readings crucial for maintaining the precise 185degF to 205degF range ideal for simmering. Infrared thermometers measure surface temperature instantly without contact, offering quick visuals but potentially missing the actual liquid temperature under simmering conditions. Accurate temperature control relies on understanding heat distribution and choosing a thermometer that best reflects the internal cooking environment for consistent simmering results.

Standard Thermometer: Features and Functionality

Standard thermometers provide precise temperature readings necessary for maintaining a consistent simmer, using a probe that can be immersed directly into the liquid. Their analog or digital displays offer accurate feedback for low-temperature cooking, ensuring optimal heat control.

- Immersion Probe - Allows direct contact with the liquid, measuring temperature at the source.

- Accurate Readings - Delivers reliable data essential for delicate simmering processes.

- Continuous Monitoring - Enables ongoing temperature tracking to prevent overheating or undercooking.

Standard thermometers are essential tools for chefs aiming to perfect simmering techniques through precise temperature management.

Infrared Thermometer: How It Works

Infrared thermometers measure surface temperature by detecting the infrared radiation emitted by the liquid or cookware during simmering. They provide quick, non-contact readings, allowing precise temperature control without disturbing the cooking process. This technology enhances safety and accuracy compared to standard thermometers that require physical immersion in the liquid.

Accuracy in Simmering: Standard vs Infrared Thermometers

Which thermometer provides more accurate temperature readings for simmering: standard or infrared? Standard thermometers measure the liquid's internal temperature directly, offering precise and consistent results essential for maintaining gentle simmering. Infrared thermometers gauge surface temperature, which can fluctuate and may not reflect the true heat throughout the pot, leading to less reliable simmer control.

Response Time: Which Thermometer is Faster?

| Thermometer Type | Response Time | Accuracy at Simmering Temperatures |

|---|---|---|

| Standard Thermometer | 30 seconds to 2 minutes | Highly accurate for liquid temperature measurement |

| Infrared Thermometer | Instantaneous (<1 second) | Reads surface temperature, less accurate for liquid simmering |

Ease of Use: Practicality in the Kitchen

Standard thermometers require direct contact with the liquid, which can be cumbersome and slow when monitoring simmering temperatures. Infrared thermometers offer instant readings without contact, enhancing convenience during cooking.

In a busy kitchen, the infrared thermometer's non-contact feature reduces the risk of contamination and mess. Standard thermometers need constant immersion and can be harder to clean, making them less practical. Infrared devices provide quick temperature checks, allowing for more efficient simmer control.

Cleaning and Maintenance Considerations

Standard thermometers require thorough cleaning after each use to prevent residue buildup, especially since their probes come into direct contact with liquids. Maintaining them involves careful sterilization to avoid corrosion and ensure accurate readings over time.

Infrared thermometers offer a more hygienic option, as they measure temperature without touching the surface, reducing the risk of contamination. Their maintenance mainly involves keeping the lens clean and avoiding exposure to extreme conditions that could damage the sensor.

Cost Comparison: Value for Cooking Enthusiasts

Standard thermometers typically cost between $10 to $30, offering precise temperature readings essential for maintaining the perfect simmer. Infrared thermometers, priced from $25 to $100, provide quick surface temperature measurements but may lack accuracy for deep liquid simmering.

Cooking enthusiasts seeking value often prefer standard thermometers due to their reliability in monitoring internal pot temperatures for simmering. Infrared models are favored for versatility and ease of use but come at a higher cost that may not justify their benefits for dedicated simmering tasks.

Related Important Terms

Spot Measurement Drift

Standard thermometers provide consistent readings during simmering with minimal spot measurement drift due to direct liquid contact, ensuring precise temperature control. Infrared thermometers may experience spot measurement drift influenced by steam and surface emissivity, causing less stable accuracy for simmering liquids.

Reflex IR Bounce

Infrared thermometers often face accuracy issues during simmering due to reflex IR bounce, where reflected infrared rays from nearby surfaces distort temperature readings. Standard thermometers provide more reliable, direct contact measurements, ensuring precise monitoring of simmering temperatures without interference from surrounding heat reflections.

Lid-off Infrared Bias

Infrared thermometers often show higher readings during simmering due to lid-off heat loss, causing temperature bias compared to standard thermometers submerged in liquid. Standard thermometers provide more accurate simmering temperatures by measuring the actual liquid heat, unaffected by surface cooling or steam interference.

Probe Immersion Lag

Standard thermometers require full probe immersion in liquids, causing lag in temperature readings during simmering due to slow heat transfer. Infrared thermometers measure surface temperature instantly without probe immersion, eliminating lag but may miss accurate internal liquid temperatures during simmering.

Surface Emissivity Factor

Standard thermometers measure liquid temperature directly through physical contact, providing accurate readings unaffected by surface emissivity variations. Infrared thermometers rely on surface emissivity to detect temperature, often requiring adjustments or calibration for simmering liquids to ensure precise surface temperature measurement.

Pan Material Thermal Profile

Standard thermometers provide accurate readings by direct contact with the liquid, making them effective for simmering in pans with uniform thermal conductivity like stainless steel. Infrared thermometers, relying on surface emissivity, can yield inconsistent readings on varying pan materials such as cast iron or non-stick coatings due to uneven thermal profiles.

IR Cone Angle Limitation

Infrared thermometers used for simmering have a cone angle limitation that affects temperature accuracy by measuring a broader surface area, potentially including steam or adjacent heat sources. Standard thermometers provide direct contact readings, ensuring precise temperature measurement critical for maintaining consistent simmering conditions.

Steam Interference Effect

Standard thermometers provide direct liquid temperature readings unaffected by steam, ensuring accurate simmering control, while infrared thermometers may yield erratic results due to steam interference reflecting infrared radiation. Using a standard thermometer is preferable for precise monitoring during simmering to avoid false high temperature readings caused by steam vapor distortion.

Depth-Gradient Heat Mapping

Standard thermometers measure temperature by direct contact with the liquid, providing accurate readings at a specific depth but limited in mapping temperature gradients throughout the pot. Infrared thermometers enable non-contact surface temperature measurement, allowing for quick detection of heat distribution and depth-gradient variations critical for precise simmering control.

Standard thermometer vs Infrared thermometer for simmering. Infographic

cookingdiff.com

cookingdiff.com