Slow-cooking broth in a slow-cooker allows for gentle, consistent heat that extracts deep flavors and nutrients over several hours without boiling. In contrast, hot fill and hold methods require rapidly filling vessels with hot broth and maintaining high temperatures to ensure safety and shelf stability. Slow-cookers prioritize flavor development and ease of use, while hot fill and hold focus on sterilization and preservation for commercial or long-term storage.

Table of Comparison

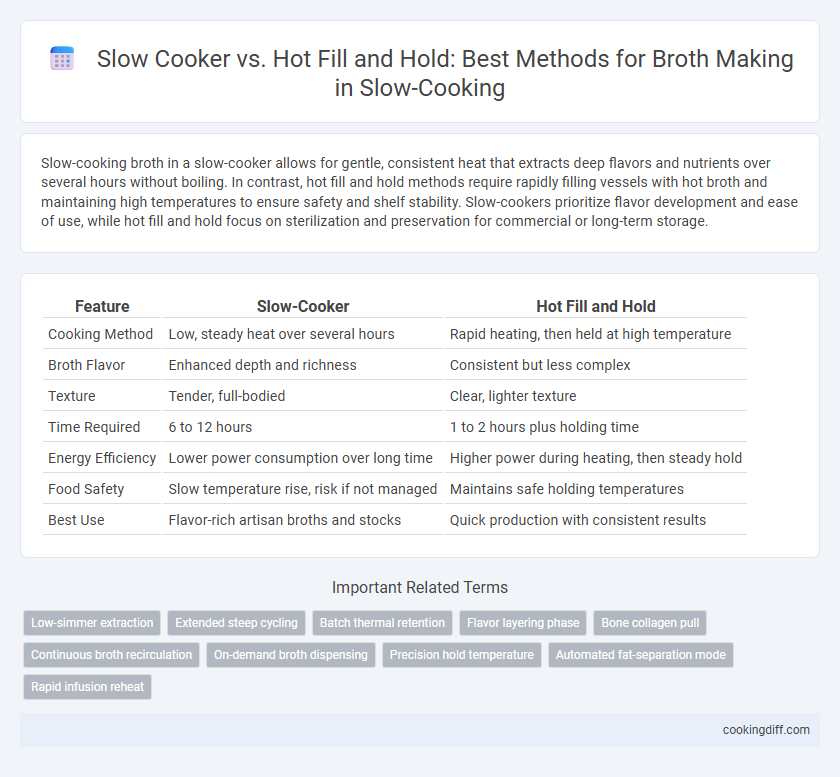

| Feature | Slow-Cooker | Hot Fill and Hold |

|---|---|---|

| Cooking Method | Low, steady heat over several hours | Rapid heating, then held at high temperature |

| Broth Flavor | Enhanced depth and richness | Consistent but less complex |

| Texture | Tender, full-bodied | Clear, lighter texture |

| Time Required | 6 to 12 hours | 1 to 2 hours plus holding time |

| Energy Efficiency | Lower power consumption over long time | Higher power during heating, then steady hold |

| Food Safety | Slow temperature rise, risk if not managed | Maintains safe holding temperatures |

| Best Use | Flavor-rich artisan broths and stocks | Quick production with consistent results |

Introduction to Broth-Making Methods

| Slow-cooker broth-making relies on low, consistent heat to extract deep flavors over several hours, preserving nutrients and yielding a rich, gelatinous texture. Hot fill and hold involves heating broth to high temperatures before sealing, which accelerates the cooking process and enhances shelf stability but may alter flavor profiles. Comparing these methods highlights trade-offs in flavor development, cooking time, and preservation techniques for optimal broth quality. |

What is Slow-Cooking Broth?

Slow-cooking broth involves simmering bones, vegetables, and herbs at low temperatures over an extended period to extract rich flavors and nutrients. Slow-cookers maintain consistent heat low enough to allow collagen breakdown and mineral release, resulting in a gelatinous and deeply flavored broth. In contrast, hot fill and hold methods rapidly bring broth to high temperatures for sterilization but lack the prolonged cooking time needed for maximum nutrient extraction and taste development.

Understanding Hot Fill and Hold Technique

The hot fill and hold technique involves cooking broth at a high temperature before immediately transferring it into sterilized containers and maintaining it at a warm temperature to prevent bacterial growth. This method ensures rapid pasteurization and extends shelf life without the need for refrigeration.

Slow-cookers, in contrast, operate at lower temperatures over long periods, allowing flavors to develop slowly but often requiring additional steps to ensure food safety. Understanding the hot fill and hold process is crucial for efficient broth production with enhanced microbial stability.

Equipment Needed for Both Methods

Slow-cookers require a programmable appliance with temperature control maintaining low heat over extended periods, essential for thorough broth extraction. Hot fill and hold demands high-temperature-resistant containers and a stove or industrial-grade kettle capable of reaching and sustaining boiling temperatures quickly. Both methods need appropriate lids and utensils, but slow-cookers offer automated temperature regulation, whereas hot fill and hold relies on manual monitoring and equipment durability.

Flavor Development: Slow-Cooker vs Hot Fill and Hold

How does flavor development differ between slow-cooker and hot fill and hold methods for broth making? Slow-cookers allow prolonged, even heat exposure that enhances the extraction of rich flavors and gelatin from bones. Hot fill and hold processes rapidly heat broth, preserving freshness but often result in less depth of flavor compared to slow simmering.

Nutrient Retention in Each Approach

Slow-cooking broth in a slow cooker preserves more heat-sensitive vitamins such as vitamin C and B-complex due to its steady, low-temperature environment. This gentle cooking method minimizes nutrient degradation compared to the hot fill and hold technique, which rapidly heats broth to high temperatures.

Hot fill and hold processes can lead to greater nutrient loss, particularly of antioxidants and volatile compounds, because of prolonged exposure to high heat. Slow cookers maintain nutrient integrity by sustaining temperatures below boiling point, optimizing the extraction and retention of minerals and collagen from bones.

Time and Energy Efficiency Compared

Slow-cookers use consistent low heat over several hours, making them more energy-efficient than hot fill and hold methods that require rapid heating and continuous maintenance of high temperatures. Hot fill and hold can reduce total cooking time but typically consume more energy due to the intense heat needed to quickly achieve safe broth temperatures.

- Slow-cookers offer steady low-energy consumption - This method maintains gentle heat over long periods, optimizing energy use for broth extraction.

- Hot fill and hold shortens cooking time - It reaches high temperatures quickly but demands more energy to sustain those temperatures throughout the process.

- Energy efficiency varies by method - Slow-cooking conserves electricity with extended low heat, whereas hot fill and hold prioritizes speed at the cost of higher energy usage.

Safety and Food Handling Considerations

Slow-cookers maintain consistent low temperatures ideal for safely breaking down bones and extracting flavors in broth. Hot fill and hold methods rapidly heat broth to high temperatures, reducing bacterial growth risks but requiring immediate cooling to prevent contamination.

- Temperature Control in Slow-Cookers - Slow-cookers operate at temperatures between 170-280degF, which are sufficient for safe broth preparation but demand extended cooking times to eliminate pathogens.

- Hot Fill and Hold Rapid Heating - This process heats broth above 185degF quickly, minimizing the time broth remains in the danger zone (40-140degF) where bacteria proliferate.

- Food Safety Handling - Slow-cooking requires careful monitoring to prevent bacterial growth during lengthy cook times, whereas hot fill and hold necessitates prompt cooling and storage to maintain safety.

Best Practices for Each Method

Slow-cookers provide consistent low heat ideal for extracting deep flavors and gelatin from bones over extended periods, while hot fill and hold methods rely on rapid heating followed by temperature maintenance to ensure broth safety and flavor retention. Choosing the appropriate method depends on balancing flavor development and food safety protocols.

- Slow-cooker temperature control - Maintain a steady 190-200degF for 8-12 hours to maximize collagen breakdown without overcooking.

- Hot fill and hold rapid heating - Bring broth to a boil quickly and hold above 135degF to inhibit bacterial growth during storage.

- Equipment suitability - Use ceramic or enamel slow-cookers to ensure even heat distribution, whereas stainless steel kettles are preferred for hot fill due to their thermal properties.

Adhering to these best practices optimizes broth quality while maintaining safety standards for each cooking technique.

Related Important Terms

Low-simmer extraction

Slow-cooker methods provide a consistent low-simmer extraction that preserves delicate flavors and nutrients, ideal for achieving rich, clear broth over extended cooking periods. In contrast, hot fill and hold techniques rapidly heat broth, often surpassing optimal simmer temperatures, which can result in cloudier stock and diminished flavor complexity.

Extended steep cycling

Slow-cooking in a slow cooker allows for extended steep cycling, which enhances the extraction of flavors and nutrients in broth making compared to hot fill and hold methods. The gradual temperature control in slow cookers maintains a consistent simmer, resulting in richer, more deeply infused broth with improved gelatin and mineral content.

Batch thermal retention

Slow-cookers maintain a consistent low temperature ideal for broth making by using batch thermal retention to evenly distribute heat over extended periods, ensuring optimal flavor extraction. In contrast, hot fill and hold methods rely on immediate high temperatures followed by insulated holding, which can cause uneven thermal gradients and less efficient flavor development in batches.

Flavor layering phase

Slow-cooker methods enhance flavor layering during broth making by gently extracting and melding ingredients over hours without rapid temperature shifts, preserving delicate aromatics and umami compounds. Hot fill and hold techniques risk interrupting this phase due to quicker heating cycles and holding processes that can diminish depth and complexity in the final broth.

Bone collagen pull

Slow-cookers extract bone collagen more effectively than hot fill and hold methods, producing a richer, gelatinous broth with enhanced mouthfeel and nutrient density. The controlled, low-temperature simmering in slow-cookers ensures thorough collagen breakdown without denaturing proteins or evaporating volatile flavors, optimizing broth quality.

Continuous broth recirculation

Slow-cookers provide consistent temperature control for gentle simmering, while hot fill and hold methods rely on rapid heating and maintaining high temperatures, which can negatively affect the delicate flavors in broth. Continuous broth recirculation in slow-cooking enhances flavor extraction and nutrient release by evenly distributing heat and ingredients, ensuring a richer and more balanced broth compared to static hot fill and hold processes.

On-demand broth dispensing

Slow-cooker broth making enhances flavor development through prolonged gentle heat, while hot fill and hold methods prioritize rapid preparation and immediate temperature control for on-demand broth dispensing. On-demand systems benefit from hot fill and hold to maintain food safety and product consistency, enabling quick access without compromising broth quality.

Precision hold temperature

Slow-cookers offer a precise hold temperature typically around 170degF to 200degF, ideal for maintaining broth quality without overcooking or bacterial growth. Hot fill and hold methods often reach higher temperatures near 212degF, which can degrade delicate flavors and nutrients in broth compared to the controlled environment of a slow-cooker.

Automated fat-separation mode

Slow-cookers with automated fat-separation mode efficiently remove excess fat from broth during the cooking process, enhancing flavor clarity and nutritional value. In contrast, hot fill and hold methods lack this built-in fat-removal feature, often requiring manual separation post-cooking.

Slow-cooker vs hot fill and hold for broth making. Infographic

cookingdiff.com

cookingdiff.com