Charcoal smoking imparts a rich, smoky flavor through natural combustion, creating a traditional taste preferred by many barbecue enthusiasts. Infrared smoking offers more precise temperature control and consistent heat distribution, reducing cooking times and producing evenly cooked meat. Choosing between charcoal and infrared depends on flavor preference and desired cooking efficiency.

Table of Comparison

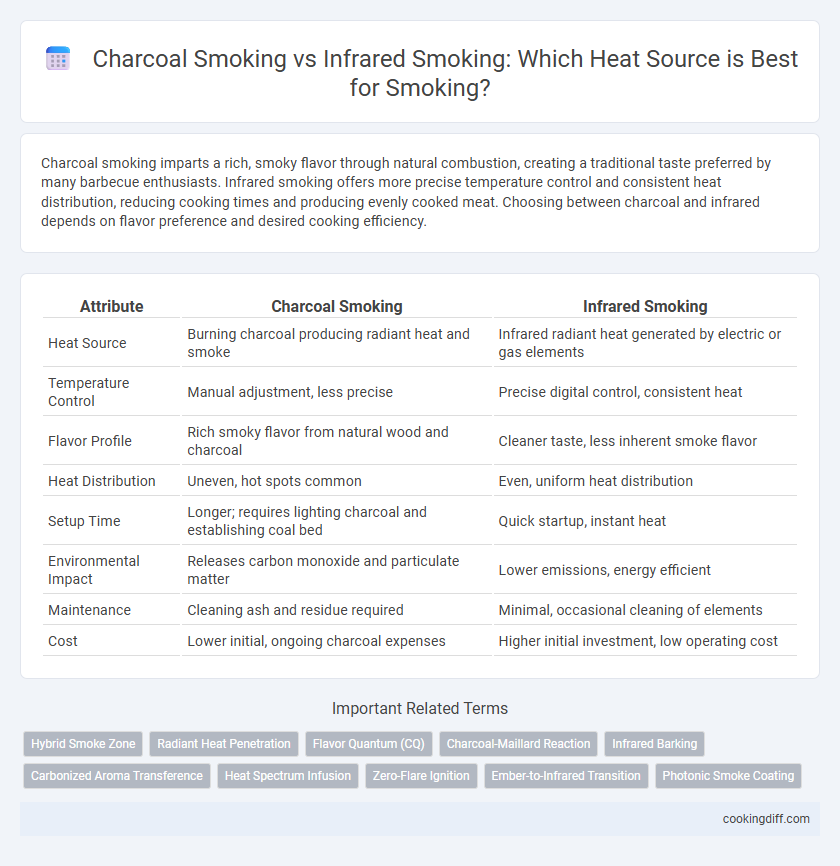

| Attribute | Charcoal Smoking | Infrared Smoking |

|---|---|---|

| Heat Source | Burning charcoal producing radiant heat and smoke | Infrared radiant heat generated by electric or gas elements |

| Temperature Control | Manual adjustment, less precise | Precise digital control, consistent heat |

| Flavor Profile | Rich smoky flavor from natural wood and charcoal | Cleaner taste, less inherent smoke flavor |

| Heat Distribution | Uneven, hot spots common | Even, uniform heat distribution |

| Setup Time | Longer; requires lighting charcoal and establishing coal bed | Quick startup, instant heat |

| Environmental Impact | Releases carbon monoxide and particulate matter | Lower emissions, energy efficient |

| Maintenance | Cleaning ash and residue required | Minimal, occasional cleaning of elements |

| Cost | Lower initial, ongoing charcoal expenses | Higher initial investment, low operating cost |

Introduction to Charcoal and Infrared Smoking

Charcoal smoking utilizes burning charcoal briquettes or lump charcoal to generate a consistent, smoky heat ideal for traditional barbecue flavors. Infrared smoking employs infrared radiation to produce even, direct heat with faster temperature recovery and reduced flare-ups.

Charcoal smoking is prized for imparting rich, authentic smoky aromas, often preferred by barbecue enthusiasts seeking deep flavor complexity. Infrared smokers offer precise temperature control and energy efficiency, making them suitable for both indoor use and quick cooking sessions. Both methods provide distinct advantages depending on desired taste, cooking time, and heat distribution preferences.

How Charcoal Smoking Works

Charcoal smoking uses burning charcoal briquettes or lump charcoal to generate consistent heat and smoky flavor, producing temperatures typically between 225degF and 275degF. As the charcoal combusts, it emits smoke rich in aromatic compounds that infuse foods with a distinctive, robust taste favored in traditional barbecue. The heat from charcoal is often adjusted by adding or removing coals and controlling airflow through vents in the smoker.

The Science Behind Infrared Smoking

| Charcoal Smoking | Uses burning charcoal to generate heat and smoke, which imparts a distinctive smoky flavor through combustion byproducts. This traditional method relies on radiant heat and actual smoke particles to flavor and cook the food. |

| Infrared Smoking | Employs infrared radiation to produce heat, which penetrates food evenly without direct flame or combustion smoke. Infrared heat minimizes temperature fluctuations and reduces smoke particulates, resulting in a cleaner cooking process while preserving flavor and moisture. |

| The Science Behind Infrared Smoking | Infrared radiation transfers energy directly to food molecules, causing rapid heating at the molecular level without requiring high ambient air temperatures. This focused heat improves cooking efficiency and consistency while reducing harmful byproducts typically generated by charcoal combustion. Infrared systems also allow precise temperature control, enhancing flavor retention and texture quality in smoked foods. |

Flavor Differences: Charcoal vs Infrared

Charcoal smoking infuses food with a rich, smoky flavor due to the natural combustion of wood and charcoal, creating complex aroma compounds. Infrared smoking, however, provides more consistent heat without imparting intense smokiness, resulting in a cleaner, less smoky taste.

Charcoal's direct flame interaction enhances meat's caramelization and adds a distinctive, robust profile favored by traditional barbecue enthusiasts. Infrared heat produces even cooking and reduces flare-ups, preserving natural food flavors while delivering subtle smokiness.

Heat Control and Consistency Compared

Charcoal smoking offers traditional smoky flavor but often struggles with inconsistent heat control due to fluctuating ember temperatures. Infrared smoking provides precise and stable heat, ensuring even cooking and better temperature management throughout the smoking process.

- Charcoal Heat Variation - Heat levels can vary significantly as charcoal burns unevenly, requiring frequent adjustments to maintain desired temperatures.

- Infrared Consistency - Infrared burners deliver uniform heat distribution, reducing hot spots and temperature fluctuations during smoking.

- Temperature Control - Infrared systems incorporate built-in controls for precise temperature settings, enhancing smoking reliability compared to manual charcoal methods.

Setup and Maintenance Requirements

Charcoal smoking demands frequent replenishment of charcoal and monitoring ash buildup to maintain consistent heat, requiring more hands-on setup and cleanup. Infrared smoking uses an electric or gas-powered element with minimal residue, simplifying maintenance and reducing downtime.

- Charcoal Setup - Requires arranging coals and controlling airflow for temperature regulation.

- Infrared Setup - Involves installing an electric or gas infrared emitter with precise temperature controls.

- Maintenance Differences - Charcoal ash must be cleaned regularly, whereas infrared elements need occasional inspection without ash removal.

Cooking Speed and Efficiency

Charcoal smoking provides a traditional heat source that delivers deep, smoky flavors but generally requires longer cooking times due to slower heat buildup. Infrared smoking uses radiant heat to cook food faster and more efficiently by directly heating the meat rather than the surrounding air.

- Cooking Speed - Infrared smokers can reduce cooking time by up to 30% compared to charcoal smokers.

- Heat Efficiency - Infrared technology converts almost 90% of energy into heat, while charcoal produces more heat loss.

- Temperature Control - Infrared smokers maintain consistent heat with less fluctuation than charcoal, improving cooking precision.

Choosing infrared smoking enhances cooking speed and energy efficiency without compromising flavor depth.

Cost Analysis: Initial and Ongoing Expenses

Charcoal smoking requires investment in high-quality lump charcoal or briquettes, which typically cost between $10 to $30 per 10-pound bag, with frequent replenishment needed for extended smoking sessions. Infrared smokers have a higher initial cost, often ranging from $300 to $800, but use electricity, leading to lower ongoing fuel expenses compared to charcoal.

Maintenance costs for charcoal smokers include regular cleaning of ash and potential replacement of grates, which may add to long-term expenses. Infrared smokers benefit from minimal maintenance and generally lower utility bills, making them more cost-effective over time for frequent use.

Health and Safety Considerations

Charcoal smoking releases higher levels of carcinogens such as polycyclic aromatic hydrocarbons (PAHs), posing increased health risks compared to infrared smoking, which emits fewer harmful pollutants. Infrared heat sources offer more precise temperature control, reducing the risk of food contamination and improving overall cooking safety. Choosing infrared over charcoal can significantly reduce exposure to smoke-related toxins and lower the potential for fire hazards in smoking environments.

Related Important Terms

Hybrid Smoke Zone

Hybrid Smoke Zone combines the deep, rich flavor of charcoal smoking with the precise temperature control of infrared heating, creating an optimal environment for consistent smoke infusion. This innovative heat source enhances meat tenderness and smoke ring development by balancing radiant heat and steady smoke production.

Radiant Heat Penetration

Charcoal smoking generates intense radiant heat that deeply penetrates meat, enhancing flavor and creating a distinct smoky crust. Infrared smoking provides more uniform heat distribution with less deep heat penetration, resulting in a gentler cooking process that preserves moisture.

Flavor Quantum (CQ)

Charcoal smoking delivers rich, smoky flavors by infusing food with aromatic compounds from natural wood combustion, creating a traditional, robust taste profile. Infrared smoking, utilizing radiant heat, offers precise temperature control but produces a milder flavor lacking the depth and complexity of charcoal's authentic smoke essence.

Charcoal-Maillard Reaction

Charcoal smoking enhances flavor through the Maillard reaction by reaching higher, uneven temperatures that promote complex caramelization and browning of proteins and sugars in meat. Infrared smoking provides more consistent heat but lacks the intense, smoky environment necessary for the deep Maillard reaction flavors characteristic of traditional charcoal smoking.

Infrared Barking

Infrared smoking uses radiant heat to penetrate food evenly, preserving its natural moisture and enhancing flavor without the heavy smoke produced by charcoal smoking. Infrared barking creates a distinctive, crispy bark on meats by promoting Maillard reactions at controlled temperatures, offering a healthier and more precise alternative to traditional charcoal methods.

Carbonized Aroma Transference

Charcoal smoking infuses food with a rich, carbonized aroma derived from smoldering natural wood and charcoal briquettes, enhancing flavor complexity through slow combustion. Infrared smoking provides a cleaner heat source with minimal smoke, resulting in less carbonized aroma transference but more precise temperature control for delicate smoking processes.

Heat Spectrum Infusion

Charcoal smoking generates a broad heat spectrum with radiant and convective heat that infuses deep smoky flavors into meat through combustion of wood and charcoal. Infrared smoking produces concentrated, consistent infrared radiation that penetrates food at a molecular level, offering precise heat control and uniform cooking without the intense smoke profile.

Zero-Flare Ignition

Charcoal smoking provides a traditional smoky flavor through slow-burning coals but often causes flare-ups that can char food unevenly, whereas infrared smoking utilizes radiant heat to maintain consistent temperatures without flare-ups, offering a precise and zero-flare ignition method. Infrared heat sources heat food evenly and reduce the risk of burning, making them ideal for controlled smoking environments where flavor consistency is critical.

Ember-to-Infrared Transition

Charcoal smoking relies on embers producing radiant heat and smoke, creating rich, traditional flavors through slow combustion and smoke infusion. Infrared smoking, using radiant infrared heat, offers precise temperature control and rapid heating, reducing smoke particles and enabling a cleaner cooking environment compared to ember-based charcoal methods.

Charcoal Smoking vs Infrared Smoking for heat source. Infographic

cookingdiff.com

cookingdiff.com